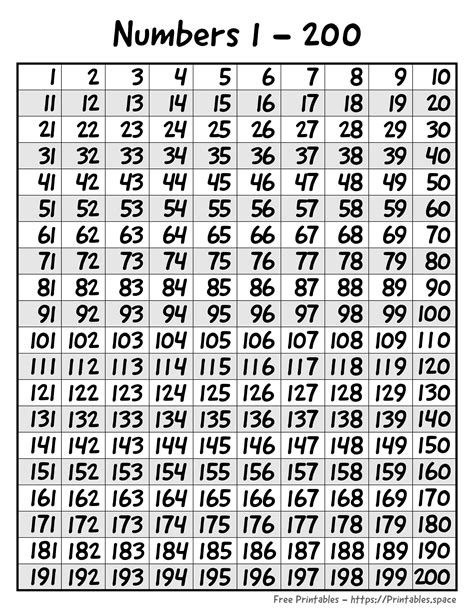

The concept of "15 out of 200" can be approached from various perspectives, depending on the context in which it is presented. In a general sense, this ratio or proportion can be seen in different fields such as statistics, quality control, education, or even in the assessment of performance metrics. To delve into the significance and applications of "15 out of 200," it's essential to consider the specific domain or scenario in which this measurement is applied.

Statistical Significance and Proportions

In statistics, the proportion of 15 out of 200 can be significant in understanding the prevalence of a particular trait, defect, or characteristic within a population or sample. This proportion translates to 7.5% (15⁄200 * 100), which can be considered low or high depending on the context. For instance, if we are talking about the failure rate of a product, a 7.5% failure rate might be deemed high and thus problematic, necessitating further investigation and corrective actions.

Quality Control and Manufacturing

In the realm of quality control, especially in manufacturing, a defect rate of 7.5% could be critical. It signifies that out of every 200 units produced, 15 are defective. This could have significant implications for customer satisfaction, brand reputation, and ultimately, the financial health of the company. Quality control measures would likely be implemented to reduce this defect rate, possibly through improved production processes, better training of staff, or enhanced quality checks.

| Defect Rate Scenario | Number of Defects | Total Units | Defect Rate (%) |

|---|---|---|---|

| Current Situation | 15 | 200 | 7.5% |

| Target Situation | 1 | 200 | 0.5% |

Educational Performance Metrics

In an educational setting, if 15 out of 200 students failed a particular exam, it might indicate a need for the educational institution to reassess its teaching methods, the difficulty level of the exam, or to provide additional support to students who are struggling. This 7.5% failure rate could prompt a review of the curriculum to ensure it is meeting the needs of all students.

Assessment and Evaluation

The process of assessing and evaluating student performance, product quality, or any other metric involves understanding the implications of ratios like 15 out of 200. It’s not just about the numbers but what they represent in terms of success, failure, or areas for improvement. Continuous assessment and evaluation are crucial for identifying trends, patterns, or anomalies that could inform decision-making processes.

Key Points

- The proportion of 15 out of 200 translates to 7.5%, which can be significant or insignificant depending on the context.

- In quality control, a 7.5% defect rate could be problematic and might require process improvements.

- In education, a 7.5% failure rate could prompt a review of teaching methods or the provision of additional student support.

- Understanding and interpreting ratios like 15 out of 200 is crucial for informed decision-making in various fields.

- Continuous assessment and evaluation are key to identifying areas for improvement and ensuring high standards of quality or performance.

Ultimately, the significance of "15 out of 200" depends on the framework within which it is analyzed. Whether it pertains to product defects, educational outcomes, or any other measurable phenomenon, this ratio serves as a metric that can guide improvements, assessments, and strategic decisions. By understanding the context and implications of such proportions, individuals and organizations can work towards achieving higher standards of quality, efficiency, and performance.

What does a ratio of 15 out of 200 typically signify?

+A ratio of 15 out of 200 signifies a proportion of 7.5%, which can indicate the prevalence of a particular trait, the success or failure rate of a process, or the quality of a product, depending on the context in which it is applied.

How is the proportion of 15 out of 200 used in quality control?

+In quality control, a proportion of 15 out of 200 might represent a defect rate, guiding the implementation of quality control measures to reduce defects and improve product reliability.

What implications might a 7.5% failure rate have in an educational setting?

+A 7.5% failure rate in an educational setting could prompt a review of the curriculum, teaching methods, and the provision of additional support to students, aiming to reduce the failure rate and improve overall educational outcomes.