Solid solutions are a fundamental concept in materials science, referring to a mixture of two or more substances where one substance is dissolved in another. This concept is crucial in understanding the properties and behaviors of various materials, from metals to semiconductors. In this article, we will delve into the world of solid solutions, exploring their definition, types, applications, and the principles that govern their formation and behavior.

Key Points

- Solid solutions are mixtures of substances where one is dissolved in another, forming a homogeneous phase.

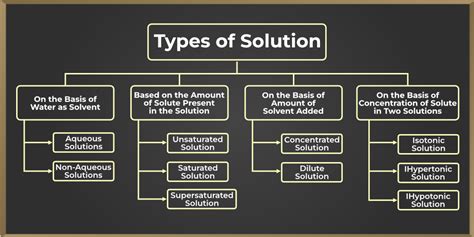

- They can be classified into substitutional and interstitial solid solutions based on the arrangement of the dissolved atoms.

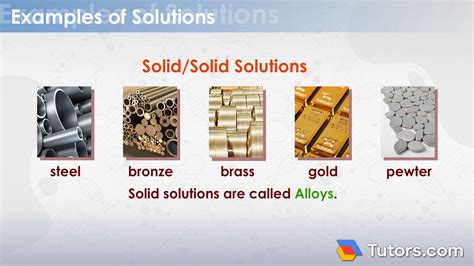

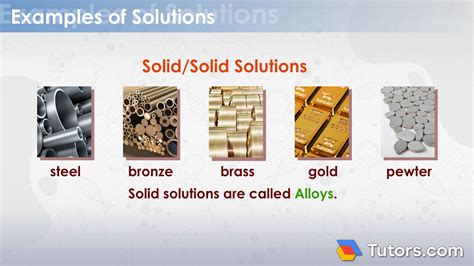

- Solid solutions have various applications, including in the production of alloys, semiconductors, and catalysts.

- The formation and properties of solid solutions are influenced by factors such as the atomic size and electronegativity of the component atoms.

- Understanding solid solutions is essential for the development of new materials with tailored properties.

Introduction to Solid Solutions

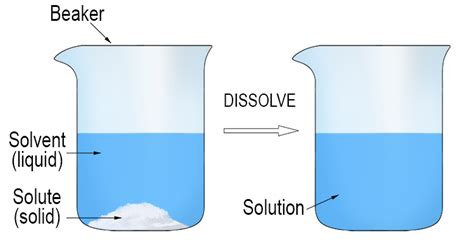

Solid solutions are typically formed when one element is dissolved in the crystal lattice of another element. The dissolved element can occupy either substitutional sites, where it replaces atoms of the host lattice, or interstitial sites, where it fits into the spaces between the host atoms. This distinction leads to two primary types of solid solutions: substitutional and interstitial.

Substitutional Solid Solutions

Substitutional solid solutions occur when the dissolved atoms replace atoms in the host crystal lattice. For this type of solution to form, the atoms of the dissolved element must be similar in size to those of the host element, typically within about 15%. This similarity in size allows the dissolved atoms to seamlessly integrate into the host lattice without significant distortion. An example of a substitutional solid solution is the alloy brass, which is a mixture of copper and zinc. In brass, zinc atoms substitute for some of the copper atoms in the crystal lattice, creating a new material with properties different from those of pure copper or zinc.

Interstitial Solid Solutions

Interstitial solid solutions, on the other hand, form when the dissolved atoms are small enough to fit into the interstitial spaces of the host lattice. These atoms do not replace host atoms but instead occupy the voids between them. This type of solution is common in transition metals, where small atoms like carbon or nitrogen can dissolve in the lattice of metals like iron or titanium. An example of an interstitial solid solution is steel, which is essentially an alloy of iron and carbon. The carbon atoms in steel occupy interstitial sites in the iron lattice, significantly altering the mechanical properties of the material compared to pure iron.

| Type of Solid Solution | Description | Example |

|---|---|---|

| Substitutional | Atoms of the dissolved element replace atoms in the host lattice. | Brass (Cu-Zn alloy) |

| Interstitial | Atoms of the dissolved element occupy spaces between the host atoms. | Steel (Fe-C alloy) |

Applications of Solid Solutions

Solid solutions have a wide range of applications across various industries. In metallurgy, they are used to create alloys with improved strength, corrosion resistance, and ductility. For instance, the addition of chromium to iron to form stainless steel enhances its resistance to corrosion. In the semiconductor industry, solid solutions of silicon with other elements like boron or phosphorus are used to create materials with specific electrical properties, which are essential for the fabrication of electronic devices.

Semiconductors and Electronics

The semiconductor industry relies heavily on solid solutions to create materials with tailored electrical properties. By carefully controlling the composition of these solid solutions, manufacturers can produce semiconductors with specific characteristics, such as conductivity type (p-type or n-type) and concentration of charge carriers. These materials are then used in the fabrication of a wide range of electronic devices, from simple diodes to complex microprocessors.

Catalysts and Chemical Reactions

Solid solutions are also used in the production of catalysts, which are materials that speed up chemical reactions without being consumed by them. By forming solid solutions of metals like platinum or palladium with other elements, catalysts can be designed to have enhanced activity and selectivity for specific chemical reactions. These catalysts are crucial in the chemical and petroleum industries for processes such as hydrogenation, oxidation, and reforming reactions.

| Application | Description | Example |

|---|---|---|

| Metallurgy | Creating alloys with improved properties. | Stainless Steel (Fe-Cr alloy) |

| Semiconductors | Producing materials with specific electrical properties. | Silicon Doped with Boron |

| Catalysts | Enhancing chemical reaction rates and selectivity. | Pt-Rh Catalyst for Automotive Exhaust |

Principles of Solid Solution Formation

The formation of solid solutions is governed by several principles, including the size factor, electronegativity, and the crystal structure of the host material. The size factor, as mentioned earlier, dictates that the atoms of the dissolved element should be of a similar size to those of the host element for substitutional solid solutions. Electronegativity differences can influence the stability and properties of the solid solution, with smaller differences often leading to more stable solutions. The crystal structure of the host material can also affect the solubility of the dissolved element and the type of solid solution formed.

Thermodynamic Considerations

The thermodynamics of solid solution formation are critical, as they determine the stability and equilibrium composition of the solution. Factors such as the enthalpy of mixing, entropy of mixing, and the temperature at which the solution is formed all play a role in determining the final composition and properties of the solid solution. Understanding these thermodynamic principles is essential for predicting the behavior of solid solutions under various conditions and for designing new materials with specific properties.

What is the primary difference between substitutional and interstitial solid solutions?

+The primary difference lies in how the dissolved atoms are accommodated in the host lattice. In substitutional solid solutions, the dissolved atoms replace host atoms, while in interstitial solid solutions, they occupy the spaces between the host atoms.

How do solid solutions influence the properties of materials?

+Solid solutions can significantly alter the mechanical, thermal, electrical, and chemical properties of materials. The exact influence depends on the type of solid solution, the composition, and the specific application.

What are some common applications of solid solutions?

+Solid solutions are used in a wide range of applications, including the production of alloys, semiconductors, and catalysts. They are crucial in industries such as metallurgy, electronics, and chemical processing.

In conclusion, solid solutions play a vital role in materials science, enabling the creation of materials with tailored properties for specific applications. Understanding the principles of solid solution formation, including the factors that influence their stability and properties, is essential for the development of new materials and technologies. As research and innovation continue to advance, the importance of solid solutions in driving technological progress will only continue to grow.