When undertaking electrical projects, one of the most critical decisions you’ll face relates to wiring specifications—especially the gauge of wire needed to ensure safety, efficiency, and compliance with electrical standards. Choosing the right 50 Amp wire isn’t just about matching a number; it involves understanding the intricate interplay between wire gauge, material properties, insulation types, circuit demands, and local electrical codes. The correct selection guarantees optimal current capacity, minimizes voltage drops, and reduces the risk of overheating or electrical fires. As an experienced electrical technician with over 15 years in residential, commercial, and industrial wiring, I emphasize that meticulous planning at this stage can prevent costly repairs, safety hazards, or code violations down the line. This comprehensive guide aims to demystify the process for DIY enthusiasts and professionals alike, anchoring decisions in technical precision while highlighting practical considerations that often extend beyond mere wire gauge.

Understanding the Basics of Ampacity and Wire Gauge

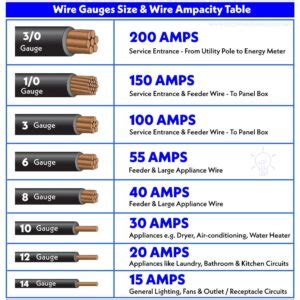

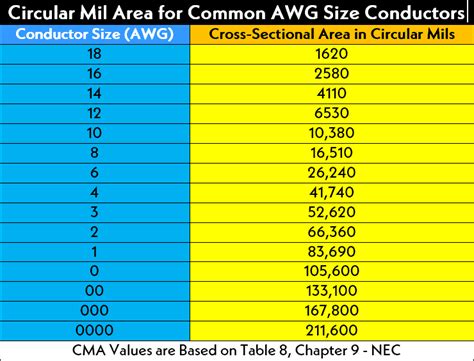

Before delving into specific wire types suitable for 50 Amp circuits, it’s essential to grasp the concept of ampacity—the maximum amount of electrical current a wire can safely conduct without exceeding its temperature rating. Ampacity depends on several factors, including conductor material, insulation type, ambient temperature, and bundling conditions. Standard wire gauges—a system that indicates the cross-sectional area—are expressed in American Wire Gauge (AWG). The smaller the AWG number, the thicker the wire and the higher its current-carrying capacity. For example, a 6 AWG copper wire can handle approximately 55 amps under typical conditions, thus making it a common choice for 50 Amp circuits. However, this is a general rule, and exact capacity can vary with installation nuances and code requirements.

Key Factors Influencing 50 Amp Wire Choice

Several interconnected factors influence the optimal wire selection for 50 Amp applications. These include:

- Conductor Material: Copper versus aluminum conductors—copper is more conductive, allowing for smaller gauge wires for the same amperage, but aluminum offers cost advantages at the expense of increased gauge size.

- Insulation Type: Different insulation ratings (e.g., THHN, THWN, RHW) impact the maximum allowable temperature and, consequently, ampacity. Higher temperature rated insulations permit thinner wires under certain conditions.

- Ambient Temperature: Elevated temperatures reduce the ampacity of conductors. For instance, a wire rated at 55 amps in standard conditions may only be rated for 45 amps in a 40°C environment.

- Installation Method: Burying, conduit type, and bundling significantly influence heat dissipation. Tightly packed bundles or underground conduits impede cooling, necessitating larger gauge wires.

- Voltage Drop Considerations: Over long runs, voltage drop becomes significant. To preserve power quality, opting for a slightly larger wire gauge may be advisable to limit voltage drops to below 3%.

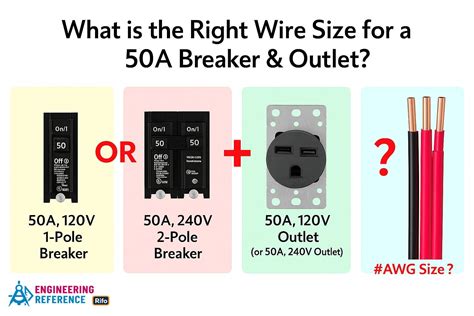

Decoding the Appropriate AWG for 50 Amp Circuits

In standard residential and commercial wiring, the American Wire Gauge system is most prevalent. The general consensus, backed by the National Electrical Code (NEC), suggests that a 6 AWG copper wire suffices for 50 Amp circuits when used with appropriate overcurrent protection devices. Conversely, for aluminum or copper-clad aluminum conductors, a 8 AWG or 6 AWG gauge is necessary due to lower conductivity. Importantly, NEC 310.16 table provides explicit ampacity ratings based on wire gauge and insulation type; consulting these tables ensures compliance and safety.

Specific Scenarios and Recommended Wire Sizes

Different applications and installation environments necessitate nuanced choices:

| Application | Recommended Wire Gauge |

|---|---|

| Residential 50 Amp Dryer Outlet | 6 AWG Copper |

| Pool Heaters or Spa Circuits | 6 AWG Copper with THHN insulation |

| Commercial Equipment | 6 AWG Copper or 8 AWG Aluminum, depending on load |

| Underground Feed for Outbuildings | 6 or 8 AWG, considering conduit and ambient temperature |

Material Choices: Copper versus Aluminum

Choosing between copper and aluminum conductors for your 50 Amp circuit involves evaluating both technical attributes and cost considerations. Copper wiring offers superior conductivity, durability, and flexibility, with a typical ampacity of approximately 55 amps for 6 AWG. Its resistance to corrosion and proven long-term performance make it a favorite for residential wiring. On the other hand, aluminum wiring—commonly used in large commercial or industrial applications—has a lower cost per foot but requires larger gauge wire (e.g., 8 AWG for similar ampacity) due to its inherently higher resistance. Moreover, aluminum is more susceptible to expansion and contraction with temperature changes, leading to potential connection issues if not properly installed. Proper crimping and anti-oxidation connectors further mitigate these concerns, enhancing safety and longevity.

Cost Implications and Long-term Considerations

While initial material costs favor aluminum wiring, the long-term expenses associated with maintenance, potential upgrades, and safety inspections often favor copper wiring. For instance, the replacement of aluminum connectors or extensive corrosion prevention can offset upfront savings. Industry data indicates that copper wiring, despite being approximately 2-3 times more expensive per gauge, can reduce the risk of electrical failures and fire hazards, leading to lower total ownership costs over a building’s lifespan.

| Material | Typical Ampacity for 6 AWG |

|---|---|

| Copper | 55 Amps |

| Aluminum | 50 Amps |

Installation Best Practices for 50 Amp Wiring

Correct installation is as vital as selecting the proper wire gauge. Ensuring safety and compliance involves adhering to several industry best practices:

- Proper Conduit Sizing: Use conduit with adequate diameter to prevent physical deformation and facilitate heat dissipation. For example, a 6 AWG wire typically requires at least Schedule 40 PVC or ½-inch EMT conduit.

- Secure Connections: Terminate wires with appropriately rated connectors, ensuring tight, corrosion-resistant terminations. Loose connections are a leading cause of overheating and failures.

- Avoid Bending Radii Violations: Follow manufacturer specifications for minimum bending radii to prevent damage to the wire’s insulation and conductor.

- Protection Against Mechanical Damage: Use suitable conduit, protective plates, or covers in high-traffic or outdoor installations to prevent physical compromise.

- Grounding and Bonding: Ensure proper grounding conductors accompany the circuit wiring, and bonding makes effective electrical contact with grounding electrodes.

Preventing Common Wiring Mistakes

Common pitfalls include oversizing or undersizing conductors, improper termination, and neglecting local code amendments. Overly tight bends in conduit can cause insulation damage, while excessively loose conduit filling can inhibit heat dissipation. Regular inspections, adherence to the NEC, and consultation with licensed electricians help mitigate these issues, resulting in durable, safe wiring systems.

Long-Term Implications and Evolving Standards

The landscape of electrical wiring continually evolves, driven by advancements in insulation technology, material science, and changing safety standards. Recent updates to the NEC emphasize reinforcement of grounding protocols and the adoption of insulated grounding conductors, which impact wiring choices for 50 Amp circuits. Additionally, increased emphasis on energy efficiency and smart home compatibility influences wire selection, ensuring circuits can handle higher loads or integrate with monitoring systems. Staying abreast of these developments ensures that your wiring decisions remain compliant and future-proofed.

How do I determine the exact wire gauge needed for a long-distance 50 Amp circuit?

+Calculating voltage drop over long runs involves considering the wire length, load current, and acceptable voltage loss—usually less than 3%. Using the formula: Voltage Drop = (2 x Length x Resistance x Current) / 1000, you can choose a slightly larger gauge to compensate. For example, if running over 100 feet, upgrading from 6 AWG to 4 AWG copper wire may significantly reduce voltage drop.

Are there specific code requirements for outdoor 50 Amp wiring installations?

+Yes. Outdoor wiring must comply with specific codes such as the NEC Article 250 for grounding and NEC Article 300 for wiring methods. Use weather-resistant insulation (like THWN or THHN), appropriate conduit materials, and secured grounding methods. Additionally, installations often require weatherproof outlets and GFCI protection if specified by local codes or application standards.

What safety precautions should I take when handling 50 Amp wiring?

+Always disconnect power before work, use insulated tools, verify the absence of voltage with a multimeter, and adhere to local electrical codes. Proper PPE, such as gloves and eye protection, is essential. If unsure about installation, consulting a licensed electrician is advisable to prevent hazards like electric shock or fire.