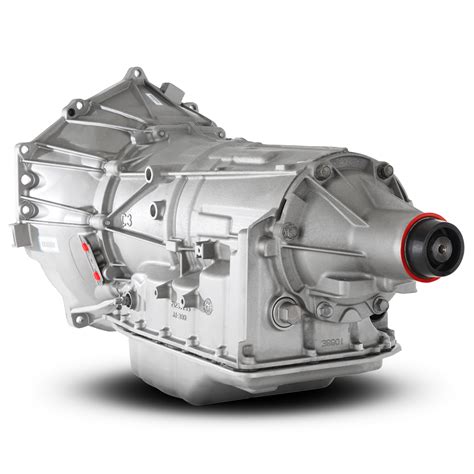

The 6L80 transmission system, a marvel of engineering in the realm of automotive technology, epitomizes the convergence of precision manufacturing, advanced control algorithms, and next-generation materials. Developed by General Motors and introduced in the early 2010s, this 6-speed automatic transmission exemplifies high-performance, efficiency, and durability tailored for a variety of vehicle platforms ranging from premium sedans to robust SUVs. Its significance in the automotive landscape is underscored by its intricate design and technological sophistication, making it an essential subject of study for automotive engineers, enthusiasts, and repair specialists alike. Understanding the comprehensive workings of the 6L80 system involves delving into its mechanical architecture, electronic controls, hydraulic systems, and the evolution of transmission technology that ultimately informs its reliability and performance metrics.

Overview of the 6L80 Transmission System

The 6L80 transmission is a product of meticulous design aimed at offering seamless gear shifts, improved fuel economy, and enhanced driving dynamics. It integrates a series of advanced components—including a cast aluminum case, multi-plate clutch packs, and electronically controlled gear selectors—forming a system that balances power transfer efficiency with driver comfort. Notably, this transmission has been used extensively in vehicles equipped with large-displacement V8 engines, such as the Chevrolet Silverado, Corvette, and some Cadillac models, highlighting its capacity for handling high torque loads up to 464 lb-ft. A chief feature is its six forward speeds, which provide optimized gear ratios for various driving conditions, from acceleration to highway cruising. The engineering behind the 6L80 incorporates refinement over previous models like the 4L80E, emphasizing durability improvements and electronic integration for better fault detection and adaptive shift control.

Mechanical Architecture and Hydraulic Systems in the 6L80

The core mechanical structure of the 6L80 relies on a complex network of planetary gear sets, clutch packs, and hydraulic circuits that coordinate to produce precise gear ratios. Constructed with high-strength steels and cast aluminum components, the transmission’s physical framework ensures both robustness and weight reduction. Central to its operation is a hydraulic control system that manages clutch engagement, band activation, and fluid pressure regulation. These hydraulic circuits are actuated via solenoids controlled by the transmission control module (TCM). Hydraulic pressure is precisely modulated to enable smooth gear changes and prevent damage during aggressive driving scenarios. The transmission employs a direct clutch, a overdrive clutch, and multiple brake bands, all working in concert to facilitate the complex shifting patterns requisite for modern engines’ torque curves.

| Relevant Category | Substantive Data |

|---|---|

| Torque Capacity | Up to 464 lb-ft, suitable for high-displacement V8 engines, with a durability system designed for 150,000+ miles under normal conditions |

| Gear Ratios | First gear: 3.06; Sixth gear: 0.67; Overdrive ratio: 0.67; providing a balance of acceleration and fuel efficiency |

| Transmission Fluid Capacity | Approximately 10 quarts, with synthetic fluids recommended for optimal performance and longevity |

The Electronic Control Unit and Shift Logic

Behind the seamless operation of the 6L80 is its sophisticated electronic control system, a key differentiator from its mechanically-controlled predecessors. The TCM integrates input from numerous sensors—including vehicle speed, throttle position, engine torque, and oil temperature—to modulate solenoid actuation dynamically. Modern control algorithms utilize adaptive learning to refine shift quality over time, accommodating driver behavior and operating conditions. The TCM also communicates with other vehicle systems via Controller Area Network (CAN) bus, providing diagnostic data and fault codes in real-time. This interconnectivity enhances fault diagnosis, facilitates software updates, and supports features such as manual shifting modes and tow/haul functions, which optimize the transmission’s response for specific driving scenarios.

Shift Quality and Driver Experience

The shift strategy of the 6L80 emphasizes smoothness and responsiveness. By leveraging multi-variable control maps, the system can decide the optimal timing for shifts—balancing engine load, road inclination, and driver intent. Notably, the transmission employs a torque converter lock-up clutch with an advanced controller to eliminate slip during cruising, improving efficiency. The driver perceives this as a seamless acceleration or deceleration, making the ride feel refined even under demanding conditions. Critics and users alike have appreciated its ability to adapt to various payloads and towing loads, making it a versatile choice across a broad spectrum of automotive applications.

Fault Detection, Diagnostics, and Maintenance

Given its complexity, regular diagnostics of the 6L80 are vital for ensuring longevity and performance. The TCM constantly monitors parameters like hydraulic pressure, solenoid operations, and torque converter behavior. When anomalies arise—such as slipping clutches, solenoid failures, or sensor malfunctions—the system logs specific fault codes accessible via diagnostic tools. Common issues include solenoid circuit faults, which can manifest as rough shifting or delayed engagement. Routine maintenance, including fluid changes every 30,000 to 60,000 miles with OEM-approved synthetic oils, plays a critical role in reducing wear on clutch packs and hydraulic components. Upgrading to high-quality fluids with additives designed to withstand higher temperatures and oxidative stress can substantially extend the system’s operational life.

| Common Fault | Implication |

|---|---|

| Solenoid failure | Erratic shifting, possible transmission slip; often resolved through electrical diagnostics and replacement |

| Hydraulic fluid degradation | Reduced hydraulic pressure, resulting in harsh or delayed shifts |

| Torque converter issues | Shuddering on lock-up, loss of efficiency, requiring thorough inspection or replacement |

Evolution and Comparison with Legacy Transmissions

The 6L80’s development marked a pivotal shift from earlier GM transmissions like the 4L80E, which relied more heavily on mechanical links and less sophisticated electronic controls. The evolutionary leap was driven by the need for better fuel economy, reduced emissions, and enhanced adaptability to diverse engine loads. Compared to its predecessor, the 6L80 offers increased gear ratios, improved torque handling, and electronic features such as adaptive shift scheduling. In comparative analyses, some critique its complexity and higher repair costs; however, its performance benefits have cemented its status as a benchmark in modern automatic transmissions. Its modular design facilitates easier repair and upgrading, fostering sustainable use despite the intricate control systems.

Historical Context and Market Adoption

Since its debut, the 6L80 has found wide adoption in GM’s heavy-duty and performance vehicles, underscoring its versatility. It replaced older models in numerous applications and incorporated lessons learned from earlier transmission platforms—namely durability, shift smoothness, and control precision. As automotive markets trend toward electrification and hybridization, the 6L80’s role, while still critical in traditional powertrain vehicles, exemplifies the pinnacle of internal combustion transmission engineering. Its evolution includes firmware updates and material enhancements that extend its lifespan and adapt to changing operational demands.

Key Points

- Advanced Mechanical Design: Combines planetary gearsets with hydraulic clutch packs for durability and smoothness.

- Electronic Control Superiority: Integrates adaptive algorithms, fault diagnostics, and driver customization features.

- Maintenance Strategies: Regular fluid changes and diagnostics are vital for longevity.

- Industry Significance: Represents a benchmark in high-torque, multi-speed transmissions for modern vehicles.

- Future Outlook: Continues to influence next-gen transmission design, especially with shifting automotive propulsion paradigms.

What are the common signs indicating a failing 6L80 transmission?

+Signs of impending transmission failure include delayed or harsh shifting, slipping gears, abnormal noises during operation, and fluid leaks. Vehicle diagnostic trouble codes such as P0770 (pressure control solenoid) or P0796 (torque converter lock-up) often confirm issues. Prompt diagnostics and maintenance can prevent complete system failure and costly repairs.

How often should I perform maintenance on the 6L80 transmission?

+Typically, transmission fluid should be replaced every 30,000 to 60,000 miles depending on driving conditions. Severe usage, such as towing or frequent stop-and-go traffic, warrants more frequent checks. Using high-quality synthetic fluids and keeping an eye on fluid color and smell enhances longevity. Regular diagnostics are recommended for early detection of developing issues.

Can the 6L80 transmission be upgraded for higher performance?

+Yes, performance upgrades are possible through stronger clutch packs, reinforced gearsets, and tuned control software. Many aftermarket providers offer upgrades to increase torque capacity and shift speed. However, such modifications should be undertaken with consideration of vehicle application and load demands, ideally under professional supervision to maintain reliability.