Converting millimeters to inches is a common task in various fields, from engineering and manufacturing to everyday measurements. Though at first glance, the two units seem worlds apart—millimeters being a metric unit and inches a conventional imperial measurement—understanding the fundamental conversion factor turns this seemingly complex process into a straightforward calculation. This article delves into the precise methods for converting 750 mm into inches, exploring the underlying principles, providing practical examples, and offering expert insights to enhance your measurement accuracy.

Understanding the Metric to Imperial Conversion: Why It Matters

In an increasingly globalized world, the need to switch seamlessly between metric and imperial systems remains vital. Whether you’re designing machinery that specifies dimensions in millimeters or interpreting technical drawings that use inches, clarity in conversion processes reduces errors and improves project efficiency.

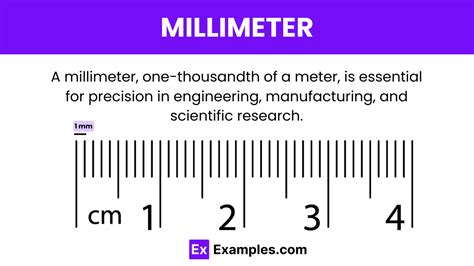

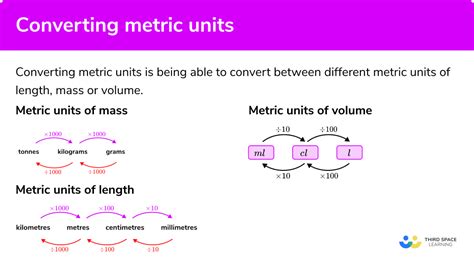

A key reason behind precise conversions is the slight variations in measurement standards historically adopted by different countries. The metric system’s simplicity, based on powers of ten, contrasts with the imperial system’s more intricate fractions. When it comes to converting millimeters to inches, grounding your calculations in the established conversion factor ensures reliability, particularly when exact measurements are critical, such as in manufacturing tolerances or scientific experiments.

Key Points

- Conversion factor accuracy is essential: 1 inch equals exactly 25.4 millimeters, forming the cornerstone of measurement conversions.

- Precision in conversion impacts quality: In fields like aerospace or mechanical engineering, even fractions of a millimeter matter significantly.

- Practical examples simplify learning: Applying real-world conversion scenarios enhances understanding and retention.

- Understanding the principles prevents errors: Recognizing the origin and reliability of conversion factors helps maintain measurement integrity.

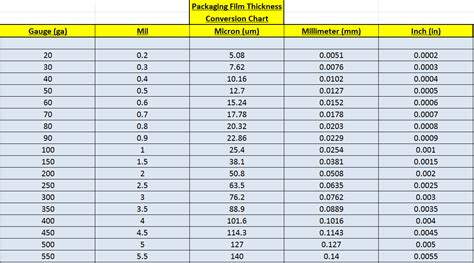

- Expert practices include using verified tools: Digital calipers, conversion charts, and software all rely on the same fundamental ratios for accuracy.

Fundamental Conversion Principles: Millimeters to Inches

The essential conversion principle rests on the fact that one inch equals exactly 25.4 millimeters. This standardized measurement was adopted by international agreement in 1959, making it the definitive benchmark for metric-international conversions. As such, converting from millimeters to inches entails dividing the millimeter measurement by this factor.

Mathematically, the relationship can be expressed as:

Inches = Millimeters ÷ 25.4Applying this to 750 mm:

Inches = 750 ÷ 25.4 ≈ 29.5276 inchesThis calculation yields a result with high precision, suitable for most applications requiring measurement conversions. Notably, when high precision is necessary—such as in scientific research or manufacturing—you might round the result to an appropriate number of decimal places, typically two or three.

Practical Approach to Convert 750 mm into Inches

To make the conversion process more accessible, many practitioners prefer conversion tools or simplified mental math techniques. For instance, recognizing that 25 mm approximates 1 inch simplifies calculations in less precision-critical contexts:

- Since 25 mm ≈ 1 inch, then:

- 750 mm ≈ (750 ÷ 25) inches = 30 inches

However, recall that this is an approximation, as 1 inch is precisely 25.4 mm. The minor difference—about 0.4 mm per 25 mm—becomes significant in high-precision settings.

For exact conversion, always rely on dividing by 25.4 rather than approximating. Doing so guarantees the highest accuracy, especially vital in engineering specifications or scientific data collection.

| Relevant Category | Substantive Data |

|---|---|

| Exact Conversion Factor | 1 inch = 25.4 mm — international standard since 1959 |

| Conversion Result for 750 mm | Approximately 29.5276 inches when divided precisely |

| Approximate Conversion (for quick estimates) | Around 30 inches using 25 mm ≈ 1 inch |

| Precision Level | Depends on context; scientific or engineering uses precise division, casual measurements may accept rounding to two decimal places |

Additional Tips for Accurate Conversion and Application

While the core mathematical formula is straightforward, practical factors can influence measurement accuracy. Understanding these nuances helps prevent subtle errors from impacting your work.

Using Digital Tools and Conversion Charts

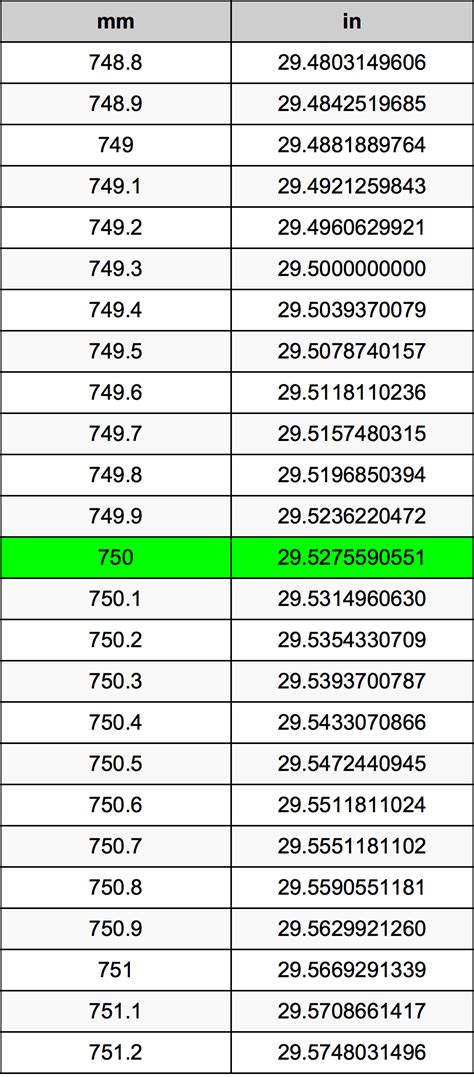

Modern measurement devices, such as digital calipers, often display measurements directly in inches or millimeters, streamlining the process. Conversion charts provide quick reference points, displaying values like 750 mm aligned with their inch equivalents, often with rounding for practicality.

For instance, a typical conversion chart might show:

- 750 mm ≈ 29.53 inches (rounded to two decimal places)

Considering Measurement Tolerances

In industrial contexts, tolerances—acceptable measurement deviations—are standardized for different components. When converting measurements, factoring in these tolerances ensures the final product fits within specified parameters.

For example, if an engineering drawing specifies a dimension of 750 mm with a tolerance of ±0.2 mm, the equivalent in inches should consider this range, translating to about:

29.53 inches ± 0.008 inches.Impacts of Rounding and Precision

Different applications require different degrees of precision. Scientific research often demands high decimal accuracy, whereas rough construction measurements might accept rounding to the nearest hundredth or even tenth.

| Application | Preferred Precision |

|---|---|

| Scientific experiments | 3-4 decimal places |

| Engineering design | 2 decimal places |

| Carpentry or DIY projects | nearest tenth or one |

Historical Context and Evolution of Measurement Standards

Understanding how these measurement standards, like 25.4 mm per inch, came into being, adds depth to the conversion process. The inch, originally based on various human body parts and historical artifacts, was standardized in the 19th and 20th centuries through international consensus to facilitate trade and scientific communication.

The metric system’s emergence in the late 18th century aimed to unify measurements, making calculations like millimeter to inch conversions straightforward. The post-1959 international agreement—ratified by countries worldwide—cemented the 25.4 mm per inch standard, greatly improving measurement consistency.

Today, digital technology and international standards ensure that such conversions are both rapid and reliable, supporting global commerce and technical innovation.

Conclusion: Mastering the Conversion from 750 mm to Inches

Converting 750 millimeters into inches exemplifies a fundamental yet vital skill in numerous domains. Armed with a solid understanding of the exact conversion factor—1 inch equaling 25.4 millimeters—and precise calculation methods, professionals and DIY enthusiasts alike can achieve high accuracy in their work.

Whether leveraging digital tools, reference charts, or manual calculations, the key is adhering to standards and understanding the context in which measurements are applied. For complex projects where tolerances matter, precision isn’t just a matter of preference but a necessity. By mastering these principles, you ensure your measurements are both accurate and meaningful in any scenario involving metric and imperial units.

What is the exact conversion factor between millimeters and inches?

+The precise conversion factor is 1 inch equals exactly 25.4 millimeters, established by international agreement in 1959. This standard allows for accurate calculation of inches from millimeters by dividing the measurement in millimeters by 25.4.

How do I convert 750 mm into inches accurately?

+Divide 750 millimeters by 25.4 to get the exact inches. Calculation: 750 ÷ 25.4 ≈ 29.5276 inches. For practical purposes, rounding to two decimal places—29.53 inches—is usually sufficient unless high precision is required.

Can I approximate 750 mm as 30 inches?

+Yes, for quick estimates, since 750 mm is close to 30 inches based on the approximation that 25 mm ≈ 1 inch. However, the precise calculation shows it’s around 29.53 inches, so be cautious where accuracy is crucial.

What tools can help me convert measurements efficiently?

+Digital calipers, conversion charts, and software applications all facilitate quick and accurate conversions. Many digital calipers, for example, can display measurements in both units simultaneously, reducing manual calculation errors.

Why is understanding measurement standards important?

+Measurement standards like the 25.4 mm per inch ensure consistency across industries and countries, preventing costly errors and ensuring components fit correctly, especially in high-stakes fields like aerospace or medical device manufacturing.