When working with measurements, it's often necessary to convert between different units, especially when dealing with projects that require precise dimensions. One common conversion is from centimeters (cm) to inches (in). Understanding how to perform this conversion is essential for various applications, including construction, design, and manufacturing. In this article, we will delve into the process of converting 9 centimeters to inches, explaining the method, providing examples, and discussing the importance of accurate conversions in different fields.

Understanding the Conversion Factor

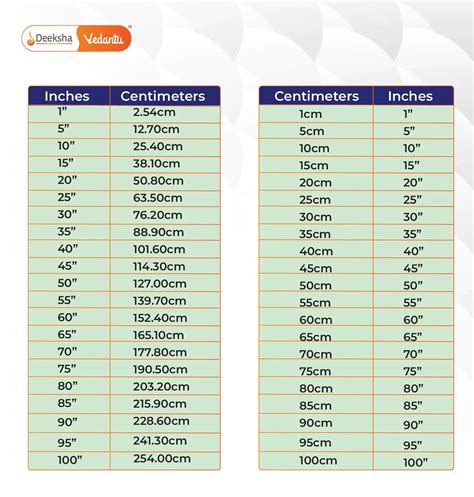

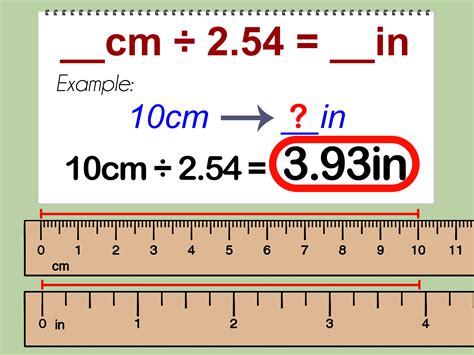

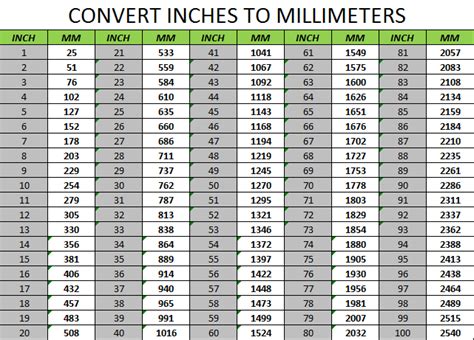

The conversion from centimeters to inches is based on the fact that 1 inch is equal to 2.54 centimeters. This relationship serves as the conversion factor. To convert centimeters to inches, you divide the number of centimeters by 2.54. This process can be applied to any measurement in centimeters to find its equivalent in inches.

Converting 9 Centimeters to Inches

To convert 9 centimeters to inches, you apply the conversion factor directly to the measurement. The calculation is as follows: 9 cm ÷ 2.54 = inches. Performing the calculation yields approximately 3.54 inches. This means that 9 centimeters is equivalent to about 3.54 inches.

| Measurement in Centimeters | Equivalent in Inches |

|---|---|

| 9 cm | Approximately 3.54 inches |

Importance of Accurate Conversions

Accurate conversions between units of measurement are crucial in many fields. In construction, for instance, incorrect conversions can lead to significant errors in building dimensions, potentially causing structural issues or failures to meet design specifications. In manufacturing, precise conversions are necessary to ensure that parts are made to the correct specifications, which is critical for the proper functioning of machinery and equipment. Similarly, in design, accurate conversions are essential for creating models and prototypes that accurately represent the final product.

Applications and Examples

Beyond the simple conversion of 9 centimeters to inches, understanding how to convert between these units has broader implications. For example, when working on a design project that requires parts to be sourced from suppliers who use different measurement systems, being able to accurately convert between systems ensures that the parts will fit together as intended. In international trade, conversions are often necessary due to the differences in measurement standards used by different countries.

Key Points

- The conversion factor from centimeters to inches is 1 inch = 2.54 cm.

- To convert centimeters to inches, divide the measurement in centimeters by 2.54.

- 9 centimeters is equivalent to approximately 3.54 inches.

- Accurate conversions are critical in construction, manufacturing, design, and international trade.

- Understanding how to convert between different units of measurement enhances project precision and reduces the risk of errors.

In conclusion, converting measurements from centimeters to inches is a straightforward process that relies on a well-defined conversion factor. The ability to perform such conversions accurately is vital for ensuring precision and avoiding errors in various fields. By understanding and applying this conversion, individuals can work more effectively across different measurement systems, contributing to the success of their projects and endeavors.

Why is it important to convert measurements accurately?

+Accurate conversions are crucial for avoiding errors in construction, manufacturing, and design. Incorrect measurements can lead to structural issues, part malfunctions, or design flaws, highlighting the importance of precision in measurement conversions.

How do I convert centimeters to inches?

+To convert centimeters to inches, divide the measurement in centimeters by 2.54. For example, to convert 9 centimeters to inches, you calculate 9 cm ÷ 2.54 = approximately 3.54 inches.

What are some fields where accurate conversions are particularly important?

+Fields such as construction, manufacturing, design, and international trade require accurate conversions. In these areas, precise measurements are critical for ensuring that projects are completed correctly, parts function as intended, and products meet design specifications.