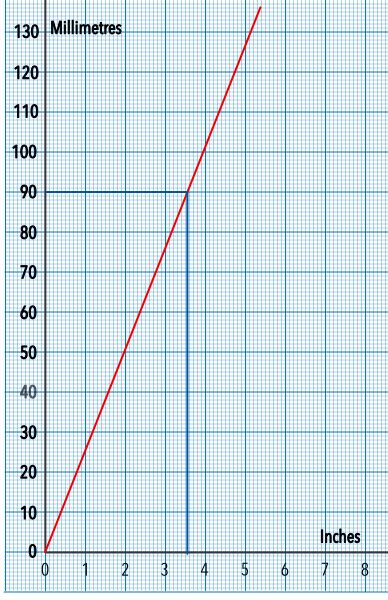

The 90mm diameter is a crucial size for various applications, including construction, manufacturing, and design. When considering the utilization of 90mm in different contexts, it's essential to delve into the specific ways this measurement can be applied. Here, we'll explore five distinct approaches to leveraging the 90mm dimension, highlighting its versatility and importance across multiple industries.

Key Points

- Construction and architecture often utilize 90mm for sizing materials and components.

- In manufacturing, 90mm can be a critical dimension for parts and machinery.

- Design and product development frequently incorporate 90mm for ergonomic and aesthetic considerations.

- Engineering applications, including piping and tubing, rely on precise 90mm measurements.

- Quality control and assurance protocols depend on accurate 90mm assessments for compliance and safety.

Construction and Architectural Applications

In the construction and architectural sectors, the 90mm measurement is significant for various elements, such as door and window frames, where it can serve as a standard size. For instance, a 90mm thick wall can provide the necessary structural integrity and insulation for a building. Moreover, components like bricks, blocks, and timber often have dimensions that are multiples or fractions of 90mm, facilitating modular construction and efficient use of materials. The use of 90mm in these applications ensures consistency and ease of assembly, contributing to the overall quality and durability of the structure.

Manufacturing and Production

In manufacturing, precision is key, and the 90mm dimension plays a vital role in the production of parts and machinery. For example, in the automotive industry, 90mm might be the diameter of a critical engine component or the width of a suspension part. Achieving this dimension with high accuracy is crucial for the performance, safety, and reliability of the vehicle. Similarly, in the aerospace sector, where materials and parts are subject to extreme stresses, the 90mm measurement could be critical for the structural integrity of aircraft components. The manufacturing process must ensure that all parts meet the required dimensions, including 90mm, to guarantee the final product’s quality and functionality.

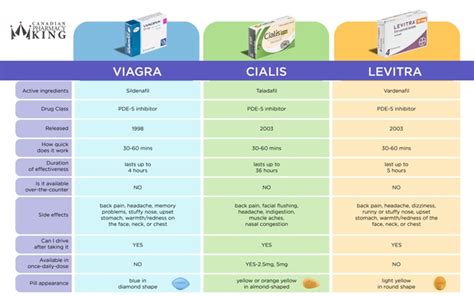

| Industry | Application of 90mm | Importance |

|---|---|---|

| Construction | Material sizing | Structural integrity and consistency |

| Manufacturing | Part dimensions | Product performance and reliability |

| Design | Ergonomics and aesthetics | User experience and product appeal |

| Engineering | Piping and tubing | System efficiency and safety |

| Quality Control | Compliance and safety assessments | Product quality and regulatory adherence |

Design and Product Development

In the realm of design and product development, the 90mm dimension can influence the ergonomic and aesthetic aspects of a product. For example, in the design of handheld devices or tools, a 90mm width might be chosen to fit comfortably in the average user’s hand, ensuring usability and comfort. Similarly, in furniture design, a 90mm thickness for table tops or shelves could provide the necessary stability while also being visually appealing. The incorporation of 90mm in design considerations reflects a balance between form and function, aiming to create products that are both appealing and practical.

Engineering Applications

Engineering fields, including mechanical, civil, and aerospace engineering, frequently encounter the 90mm dimension in various applications. In piping and tubing systems, for instance, 90mm could be a standard diameter, affecting the flow rate, pressure, and efficiency of the system. The accurate measurement and implementation of 90mm in these contexts are vital for ensuring the system’s performance, safety, and compliance with regulatory standards. Engineers must carefully consider the 90mm dimension, among others, to design and develop systems that meet the required specifications and operate effectively.

Quality Control and Assurance

Finally, in the realm of quality control and assurance, the 90mm measurement is crucial for evaluating the compliance and safety of products and structures. Quality control protocols often involve verifying that components or products meet specific dimensional requirements, including 90mm, to ensure they function as intended and meet safety standards. This process involves precise measurement tools and techniques to confirm that the 90mm dimension is accurately achieved, thereby guaranteeing the quality and reliability of the final product. The role of 90mm in quality control underscores the importance of attention to detail and adherence to specifications in manufacturing and construction.

What are the primary applications of 90mm in construction?

+The primary applications of 90mm in construction include sizing materials and components, such as door and window frames, bricks, blocks, and timber, to ensure structural integrity and ease of assembly.

How is 90mm used in manufacturing and production?

+In manufacturing, 90mm is used as a critical dimension for parts and machinery, ensuring precision and accuracy in production. This dimension is vital for the performance, safety, and reliability of the final product.

What role does 90mm play in design and product development?

+In design and product development, 90mm influences ergonomic and aesthetic considerations, aiming to create products that are both functional and visually appealing. This dimension can affect user experience and product appeal.

Meta Description: Explore the diverse applications of 90mm across industries, from construction and manufacturing to design and engineering, understanding its significance in precision and quality.