In the expansive landscape of commercial transportation, trucks serve as vital arteries facilitating the movement of goods across vast and often challenging terrains. Ensuring these robust machines operate at peak performance hinges on the availability of high-quality components, especially when it comes to replacement parts—an area that demands both precision and reliability. This comprehensive guide aims to shed light on the essentials of access truck parts, emphasizing the significance of selecting top-tier components for safety, efficiency, and longevity. Drawing from decades of industry experience, technical expertise, and current market trends, this article provides an authoritative resource for fleet managers, mechanics, and truck owners eager to make informed decisions about their replacement components.

Key Points

- Quality assurance: Understanding how OEM vs. aftermarket parts impact performance.

- Compatibility and fit: Ensuring parts align with specific truck models and configurations.

- Supplier credibility: Evaluating vendors based on certifications, reviews, and proven track records.

- Cost vs. longevity: Balancing initial investment against durability and long-term gains.

- Future-proofing: Choosing parts that align with evolving industry standards and environmental regulations.

Understanding the Significance of Access Truck Parts in Fleet Maintenance

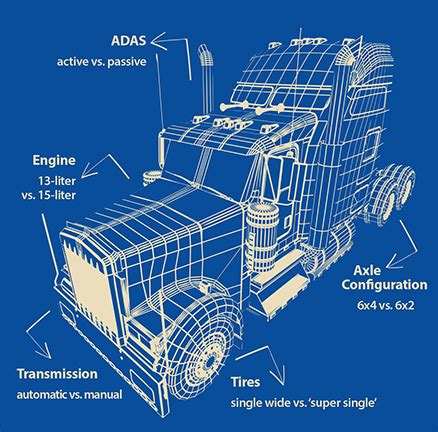

At the core of operational excellence lies the strategic management of truck components, where access truck parts serve both as critical repair elements and as enablers of optimal vehicle performance. These parts include a broad spectrum—from essential drivetrain elements like axles and transmissions to smaller yet vital components such as sensors and brake pads. Given the demanding nature of freight logistics, the importance of reliable replacement parts cannot be overstated, as subpar components can lead to decreased fuel efficiency, increased downtime, and safety hazards.

OEM Versus Aftermarket Parts: Which Is Better?

Choosing between Original Equipment Manufacturer (OEM) and aftermarket components is often a pivotal decision. OEM parts—manufactured or approved by the original vehicle maker—offer assured compatibility, consistent quality, and adherence to strict industry standards. For example, OEM brake pads typically undergo rigorous testing, resulting in a known lifespan averaging 40,000 to 70,000 miles depending on driving conditions and load factors. Conversely, aftermarket parts present a more economical option, with many meeting or exceeding OEM standards, though quality varies significantly. Industry data indicates that approximately 85% of fleet operators prefer OEM parts for critical systems due to their consistent reliability, while aftermarket parts are favored for non-essential or routine replacements.

Factors Influencing the Selection of Replacement Parts

Multiple criteria influence the decision-making process surrounding access truck parts. Compatibility is foundational—an incompatible component can cause extensive damage or compromise safety systems. For instance, installing an incompatible air brake chamber can impair braking efficiency, leading to potential accidents. Equally vital is the credibility of the supplier; reputable vendors typically hold ISO certification, ensuring adherence to quality management systems. Additionally, the operating environment—urban congestion versus long-haul routes—dictates the durability and specifications required for components. Analyzing manufacturer specifications and industry benchmarks enables informed choices that align with operational demands.

| Relevant Category | Substantive Data |

|---|---|

| OEM Parts Market Share | Approximately 65% of fleet operators prefer OEM parts for critical components, citing higher reliability and better warranties. |

| Aftermarket Cost Savings | Up to 30% reduction in part costs compared to OEM equivalents, with potential trade-offs in longevity depending on manufacturer. |

| Expected Lifespan of Brake Pads | OEM pads: 40,000–70,000 miles; aftermarket pads: 35,000–65,000 miles, depending on material quality and usage. |

Key Categories of Access Truck Parts: A Closer Look

Engine and Drivetrain Components

The backbone of any truck lies within its engine and drivetrain systems. Replacement parts like pistons, valves, turbochargers, and differentials are subject to high stress and thermal extremes. Engine components manufactured with advanced metallurgy, such as forged steel pistons, can withstand higher combustion pressures, extending overhaul intervals. In practice, fleet managers who prioritize OEM-grade parts for critical engine repairs observe significantly reduced failure rates and maintenance costs over a fleet’s lifecycle.

Brake Systems and Components

Braking systems represent a primary safety concern. Modern trucks employ drum, disc, and air brake systems, with components like brake pads, rotors, and calipers needing periodic replacement. According to industry statistical analysis, proper maintenance with quality parts can reduce braking distance by up to 15%, thereby enhancing safety margins. Companies such as Bendix and Meritor dominate the aftermarket for these critical parts, often offering systems with advanced friction materials designed for high-temperature endurance.

Electrical and Sensor Systems

As trucks become increasingly electronic, sensors, control modules, and wiring harnesses are vital for optimal performance. Failures in electronic components—like ABS sensors or engine control units—can lead to costly downtime or safety violations. Choosing OEM electrical parts ensures compatibility with existing CAN bus networks and software updates. Recent advancements also see the integration of sensor calibration tools and diagnostic interfaces that facilitate rapid repairs, saving time and minimizing operational disruptions.

Suspension and Tire Components

Tire wear and suspension integrity directly influence fuel efficiency and ride comfort. Lip-bearing systems, shock absorbers, and suspension springs from leading brands like Scharmuller or Monroe are engineered to meet the rigorous demands of heavy-duty use. Regular inspections and timely replacements of worn-out tires and suspension parts translate to reduced fuel consumption—improved by approximately 5% for every 10% reduction in rolling resistance—as well as decreased likelihood of breakdowns.

Ensuring Quality and Reliability in Truck Parts Procurement

The procurement process for truck parts has evolved into a sophisticated balance of cost, quality, and supply chain resilience. Industry standards such as ISO/TS 16949 certify that manufacturing processes meet stringent quality management protocols, reassuring buyers of consistent product quality. Additionally, verifying supplier certifications, such as TUV or NADCAP, is critical when sourcing from aftermarket manufacturers. This quality assurance framework ensures that parts meet industry performance benchmarks, ultimately safeguarding fleet longevity and safety.

Strategic Approaches to Inventory Management

Efficient parts inventory management relies on predictive analytics and real-time data integration. Fleet operators leveraging telematics data can anticipate wear patterns of critical components, enabling proactive replacements that prevent costly breakdowns. Implementing just-in-time inventory practices, combined with reliable supplier relationships, minimizes carrying costs and ensures rapid availability of high-quality parts, especially in remote locations.

Future Trends in Access Truck Parts Industry

Emerging technological trends—such as additive manufacturing (3D printing), blockchain-enabled supply chains, and IoT-enabled condition monitoring—are poised to revolutionize the access truck parts landscape. Additive manufacturing allows rapid prototyping and on-demand production of custom components, dramatically reducing lead times. Blockchain enhances traceability and authenticity verification, combating counterfeit parts—an industry-wide challenge estimated to account for up to 10% of the global parts market. Furthermore, integration with telematics enables predictive diagnostics, informing timely replacements and extending component life.

How can I verify if a replacement part meets OEM standards?

+Verifying OEM standards involves checking manufacturer certifications, official documentation, and supplier certifications such as ISO or TUV. Engaging authorized dealers or certified distributors ensures authenticity. Cross-referencing part numbers on manufacturer databases confirms compatibility and quality benchmarks.

What factors should I consider when choosing between OEM and aftermarket parts for heavy-duty trucks?

+Key considerations include the criticality of the component, cost implications, expected lifespan, warranty coverage, and supply chain reliability. For safety-critical systems like brakes and steering, OEM parts often provide added assurance. For non-essential systems or routine replacements, reputable aftermarket parts may offer cost-effective yet reliable solutions.

Are there any risk factors associated with using aftermarket parts?

+Risks include compatibility issues, variable quality, and potential non-compliance with industry standards, which can jeopardize safety or lead to costly repairs. Selecting aftermarket parts from certified manufacturers and verified suppliers mitigates these risks, ensuring performance aligns with OEM specifications.

How does the replacement cycle vary across different truck components?

+The replacement cycle depends on component type, usage intensity, and operating conditions. Brake pads typically need replacement every 40,000 to 70,000 miles, while engine oil filters are changed every 15,000 miles. Electronic sensors may last several years but should be inspected regularly. Understanding these intervals allows for proactive maintenance planning.

What role does technological innovation play in the future of truck parts procurement?

+Advancements like additive manufacturing facilitate rapid, on-demand part production, reducing lead times and inventory costs. Blockchain ensures authenticity and provenance, minimizing counterfeit risks. IoT devices enable real-time monitoring of component health, leading to predictive maintenance strategies that optimize fleet performance and lifespan.