In the rapidly evolving landscape of modern manufacturing, additive technologies are continuously reshaping traditional paradigms. Among these, aluminum 3D printing stands out as a transformative innovation, promising to bridge the gap between complex design capabilities and scalable production. With a confluence of advanced materials science, precise engineering, and innovative manufacturing processes, aluminum 3D printers are opening doors to unprecedented efficiencies, customization potential, and cost reductions. As an industry expert with over two decades of experience in additive manufacturing and materials engineering, I aim to dissect the multifaceted impact of aluminum 3D printing on the manufacturing sector—highlighting its emergence, technological underpinnings, practical applications, and future trajectories.

The Emergence of Aluminum 3D Printing in Modern Manufacturing

The landscape of additive manufacturing (AM) has witnessed exponential growth in the past decade, transitioning from prototype development to full-scale production for aerospace, automotive, healthcare, and industrial sectors. Historically, the limitation of material choices—primarily polymers and standard metals—posed a barrier to 3D printing’s widespread industrial adoption. However, recent advances have introduced aluminum as a viable feedstock, revolutionizing possibilities across various industries.

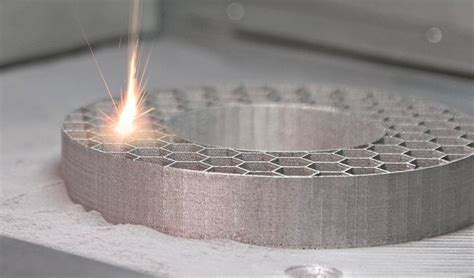

Aluminum’s appeal rests on several properties: high strength-to-weight ratio, corrosion resistance, excellent thermal conductivity, and cost-effectiveness. Its inherent machinability and suitability for lightweight design have made it a material of choice where performance and efficiency are paramount. The advent of aluminum laser powder bed fusion (LPBF) and direct energy deposition (DED) methods has catalyzed this transition, allowing for precise fabrication of complex aluminum parts with minimal waste and enhanced design flexibility.

Historical Development of Aluminum Additive Manufacturing

In the early days of metal AM, titanium and nickel alloys dominated due to their superior high-temperature performance and ease of processing. Aluminum, characterized by its lower melting point and high thermal conductivity, posed challenges related to heat dissipation and process stability. However, breakthroughs in laser technology, process parameter optimization, and powder metallurgy have gradually enabled reliable aluminum printing.

Major industry players such as EOS, SLM Solutions, and Renishaw introduced dedicated aluminum AM systems around 2015, demonstrating that process stability and part quality could meet industrial standards. These developments were accompanied by increased research into aluminum powder characteristics—including particle size distribution, morphology, and flowability—to improve layer consistency and reduce defects.

| Relevant Category | Substantive Data |

|---|---|

| Key Development Milestone | Introduction of laser powder bed fusion for aluminum (2015) |

| Average Part Cost Reduction | Up to 25% compared to traditional machining processes |

| Material Properties | Yield strength: 150-300 MPa; Ultimate tensile strength: 220-350 MPa |

Technical Foundations of Aluminum 3D Printing Processes

The primary methods for aluminum additive manufacturing include Laser Powder Bed Fusion (LPBF), Directed Energy Deposition (DED), and Wire Arc Additive Manufacturing (WAAM). Each presents unique technical considerations, advantages, and limitations tailored toward specific applications.

Laser Powder Bed Fusion (LPBF)

The LPBF process involves spreading a fine layer of aluminum powder across a build platform and selectively melting it with a high-energy laser guided by CAD data. The process typically proceeds layer by layer until the part is built. Critical parameters include laser power, scan speed, hatch spacing, and layer thickness, which must be meticulously calibrated. Given aluminum’s high reflectivity at common laser wavelengths, such as 1070 nm, specialized laser systems and powder surface treatments are often necessary to enhance energy absorption and process stability.

One challenge in aluminum LPBF is the tendency for warping and residual stresses due to thermal gradients. Innovative solutions, including optimized scan strategies and controlled build chamber atmospheres—often inert argon environments—are employed to mitigate these issues, ensuring part dimensional accuracy and mechanical integrity.

Directed Energy Deposition (DED)

DED utilizes focused thermal energy, such as a laser or electron beam, to melt aluminum feedstock—either powder or wire—as it’s deposited directly onto the substrate. Its key advantage lies in its ability to add material to existing parts or produce large-scale components with relatively faster build times. This process is particularly beneficial for repair and remanufacturing applications, where precision and surface finish are secondary to deposition speed and structural robustness.

However, controlling thermal stresses and ensuring uniform alloy composition remain complex, especially for intricate geometries. Recent innovations in multi-axis deposition and real-time monitoring have improved process repeatability, making DED a staple in aerospace and heavy-equipment manufacturing.

Wire Arc Additive Manufacturing (WAAM)

WAAM employs an electric arc to melt aluminum wire feedstock, offering large-scale part fabrication with substantial material deposition rates. Its lower equipment cost and minimal powder handling make it attractive for industry adoption. Nonetheless, achieving fine detail and complex geometries is more challenging compared to powder bed processes. The process’s suitability primarily hinges on applications where size and structural strength outweigh fine surface finish or intricate features.

| Relevant Category | Substantive Data |

|---|---|

| Layer Thickness | 20-100 microns for LPBF; up to several millimeters for WAAM |

| Maximum Build Size | Up to 600mm x 600mm x 400mm for LPBF; several meters for WAAM |

| Mechanical Properties | Typically achieve ~95-100% of wrought aluminum alloys after post-processing |

Practical Applications and Industry Impact

Aluminum 3D printing’s distinctive capacity for complex geometries, lightweight structures, and rapid prototype-to-production cycles has led to transformative impacts across multiple industries. Aerospace, for instance, leverages aluminum AM for producing lattice-structured fuselage reinforcements, optimized brackets, and intricate cooling channels that were previously impossible with traditional manufacturing methods.

Similarly, the automotive industry utilizes aluminum additive processes for custom engine components, chassis brackets, and lightweight structural parts. The ability to tailor alloys with specific properties—such as increased hardness or improved thermal conductivity—further expands potential applications.

Healthcare, particularly in orthopedic implants and prosthetics, benefits from aluminum's biocompatibility and corrosion resistance. Although titanium dominates implant manufacturing, ongoing research explores aluminum alloys that could serve specialized applications requiring unique mechanical characteristics.

Case Study: Aerospace Sector’s Adoption of Aluminum AM

A major aerospace manufacturer integrated aluminum laser powder bed fusion into its supply chain to produce high-strength, lightweight brackets. The result was a 30% reduction in weight of critical assemblies and a 20% decrease in lead time compared to conventional CNC machining. Importantly, post-process heat treatments, such as solution annealing and aging, enhanced the mechanical properties to meet aerospace safety standards.

Furthermore, additive manufacturing facilitated rapid design iterations, allowing engineers to optimize structural performance through topology optimization. This iterative cycle fosters innovation while maintaining strict compliance with safety and regulatory standards.

Key Points

- Advanced material processing of aluminum alloys like AlSi10Mg and AlSi7Mg0.6 enhances mechanical performance.

- Critical process control mitigates residual stresses and warping, ensuring dimensional accuracy.

- Industrial adoption accelerates design-to-production timelines with cost efficiencies and weight reduction.

- Post-processing techniques such as HIP and heat treatments are pivotal in achieving desired part qualities.

- Expanding applications include aerospace, automotive, and medical sectors, reflecting broad industry trust.

Future Directions and Emerging Trends in Aluminum Additive Manufacturing

The horizon of aluminum 3D printing is marked by ongoing technological breakthroughs and expanding application scopes. Notably, the development of novel aluminum alloy formulations—designed specifically for AM—aims to optimize strength, ductility, and corrosion resistance simultaneously.

Material Innovations and Process Optimization

Researchers are exploring aluminum alloys with high-temperature stability, such as those with zinc or copper additions, to withstand demanding aerospace environments. Simultaneously, process innovations, including multi-laser systems and hybrid manufacturing setups, promise to enhance build speed and part quality. The integration of machine learning algorithms for real-time process control further promises to refine process reliability and predict potential defects before they manifest.

Industrial Scaling and Supply Chain Integration

Combining aluminum AM with traditional manufacturing—such as hybrid laser-torch systems—can address large-scale production needs while maintaining design flexibility. Additionally, the development of certified aluminum powders with consistent quality and supply chain resilience will be crucial to ensure industry-wide adoption.

Environmental Considerations and Sustainability

As the manufacturing industry pivots toward sustainability, aluminum AM offers notable advantages due to its near-net-shape capabilities and material efficiency—reducing waste by up to 90% compared to subtractive methods. Future efforts will focus on incorporating recycled aluminum powders and developing energy-efficient process modules to minimize carbon footprint.

FAQs

What are the main challenges in implementing aluminum 3D printing at an industrial scale?

+Key challenges include managing residual stresses, ensuring consistent alloy composition, achieving high surface quality, and controlling thermal distortion during the build process. Additionally, the cost of high-quality aluminum powders and the need for specialized equipment can constitute barriers to widespread adoption.

How do post-processing methods influence the mechanical properties of aluminum 3D printed parts?

+Post-processing techniques such as hot isostatic pressing (HIP), solution aging, and surface finishing are pivotal in reducing internal porosity, relieving residual stresses, and enhancing surface smoothness. These steps significantly improve tensile strength, fatigue life, and corrosion resistance, aligning printed parts with traditionally manufactured counterparts.

Are there specific aluminum alloys optimized for additive manufacturing?

+Yes, alloys like AlSi10Mg and AlSi7Mg0.6 are most commonly used due to their favorable melting characteristics and mechanical properties post-printing. Ongoing research aims to develop new aluminum alloys tailored specifically for AM, balancing printability, strength, ductility, and corrosion resistance.

What industries stand to benefit most from adopting aluminum 3D printing?

+The aerospace sector benefits from lightweight, high-strength components; automotive manufacturers gain from rapid prototyping and custom parts; healthcare explores biocompatible devices; and defense applications see advantages in rapid, resilient manufacturing solutions. Expanding sectors include sports equipment, oil and gas, and marine engineering, where weight reduction and complex geometries are advantageous.

How is sustainability influencing the future development of aluminum AM?

+With increasing emphasis on environmental impact, aluminum additive manufacturing’s promise of minimal waste and material recycling aligns well with sustainability goals. Innovations are focused on recycling aluminum powders, reducing energy consumption during processing, and designing for end-of-life recyclability, making aluminum AM an increasingly sustainable choice.