The story of American car manufacturing is a testament to ingenuity, resilience, and continuous innovation. From the early days of assembly line breakthroughs pioneered by industry giants to the modern era of electric and autonomous vehicles, the evolution of this sector underscores the profound impact of technological advancement and strategic foresight. Concurrently, American foundries—long the backbone of the nation's industrial strength—have played a pivotal role in supporting automotive innovation through their development of advanced metal casting techniques. This confluence of automotive and foundry industries exemplifies how integrated manufacturing ecosystems drive economic growth, technological mastery, and global competitiveness. In this comprehensive exploration, we'll examine how American car companies and foundries have mutually reinforced each other's growth, embedding a culture of pioneering innovation that continues to shape manufacturing paradigms.

Key Points

- The unique evolution of American automotive innovation rooted in historical industrial strength and cutting-edge developments.

- Synergistic relationship between advanced foundry processes and automotive design that fostered technological breakthroughs.

- Impact of policy, economic shifts, and technological trends on fostering innovation in both sectors.

- Future prospects of American manufacturing emphasizing sustainable practices, digital transformation, and autonomous systems.

- Core strategies that enable American firms to maintain leadership in global automotive innovation.

The Historical Foundations of American Automotive and Foundry Industries

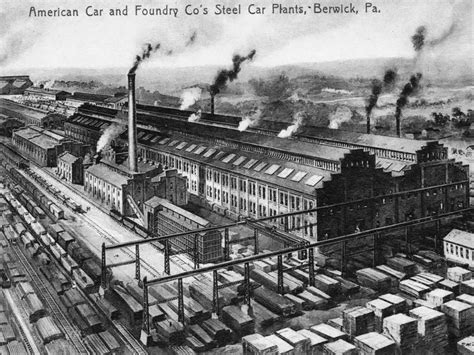

At the dawn of the 20th century, American ingenuity revolutionized transportation. The advent of mass-produced automobiles, spearheaded by visionary entities like Ford Motor Company—founded by Henry Ford in 1903—set the stage for industrial dominance. The introduction of the moving assembly line in 1913 represented a paradigm shift, lowering manufacturing costs, increasing throughput, and enabling broader market access. This innovation not only redefined automotive production but also emphasized the importance of precision metal components, many of which stemmed directly from the foundry sector.

Concurrent with automotive breakthroughs, American foundries—from the Iron and Steel industry to specialized casting facilities—began scaling operations to meet the burgeoning demand for automotive-grade parts. These foundries developed high-precision casting processes, such as sand casting and, later, die casting, that allowed for complex geometries and lightweight components, facilitating vehicle efficiency. This period laid the foundation for a symbiotic relationship between car manufacturers and foundries—each pushing the other towards higher standards of quality and innovation.

Synergistic Innovation: Foundries as Catalysts of Automotive Advancement

Advanced Casting Techniques and Material Science

Thanks to pioneering efforts in metallurgy and process engineering, American foundries have consistently integrated cutting-edge technologies like high-pressure die casting and vacuum-assisted casting. These methods enable the production of intricate engine components, chassis parts, and body panels with superior dimensional accuracy and tensile strength. For instance, the adoption of aluminum and magnesium alloys—thanks to the efforts in foundry metallurgy—has significantly reduced vehicle weight, enhancing fuel efficiency and emission standards.

One prominent example is the development of compact, lightweight engine blocks using infiltration casting methods, which have allowed manufacturers to produce more efficient and durable powertrains. The integration of nanomaterials and heat treatment innovations further advances the performance characteristics of cast components, pushing the boundaries of what automotive materials can achieve.

| Relevant Category | Substantive Data |

|---|---|

| Material Innovation | 20% reduction in component weight achieved through aluminum alloys in engine blocks since 2010 |

| Casting Precision | Dimensional tolerances improved to ±0.1mm with the adoption of vacuum-assisted casting processes |

| Production Volume | Over 150 million cast engine components produced annually in the United States |

The Evolution of American Automotive Innovation in the 21st Century

Electrification and Autonomy as New Frontiers

As the impulse to decarbonize and modernize transportation intensifies, American automakers like General Motors, Ford, and Tesla are at the forefront of adopting electrification. This shift necessitates not only new powertrain components but also precision-crafted components capable of managing high-voltage systems and thermal stresses. Foundries dedicated to developing high-temperature, corrosion-resistant castings—such as silicon carbide-infused alloys—are uniquely positioned to meet these demands.

Autonomous vehicle development further emphasizes the importance of integrating sensor housings, complex electronics casings, and lightweight chassis components—all requiring high-precision casting solutions. American foundries have responded by innovating in areas like lost foam casting—an energy-efficient process that produces complex geometries with minimal waste—thus aligning with sustainability initiatives while supporting automotive innovation.

Digital Transformation and Industry 4.0

The current manufacturing renaissance, driven by Industry 4.0 principles, has led to smart foundry establishments equipped with IoT sensors, real-time data analytics, and automation. These digital tools facilitate quality control, predictive maintenance, and customized manufacturing workflows, dramatically reducing lead times and defects.

For example, the integration of digital twin technology allows for virtual validation of casting processes before physical production, saving time and material costs. American firms leveraging such cutting-edge tools demonstrate how innovation in the foundry sector is fundamental in sustaining the agility and competitiveness of the entire automotive supply chain.

| Relevant Category | Substantive Data |

|---|---|

| Industry 4.0 Adoption | Over 60% of U.S. foundries have implemented IoT-based monitoring systems as of 2023 |

| Energy Efficiency | New casting facilities save an estimated 25% energy consumption compared to previous systems |

| Customization | On-demand, small-lot casting runs increased by 35%, enabling rapid prototyping for new vehicle models |

Driving Sustainability and Future Growth in American Manufacturing

Environmental Considerations and Green Manufacturing

Future-forward American manufacturing recognizes that sustainability is key to long-term competitiveness. The transition to green foundry practices involves recycling metals, utilizing renewable energy sources, and minimizing waste through advanced casting techniques. For example, electric arc furnace (EAF) technology and submerged arc remelting processes have been adopted to produce high-grade alloys with lower carbon footprints.

Similarly, automation reduces material waste, and process optimization via AI-driven analytics leads to less energy use. Moreover, initiatives like establishing closed-loop water systems and particulate filtering significantly diminish environmental impact, aligning the industry with national and global carbon neutrality goals.

Global Competitiveness and Innovation Leadership

American firms, bolstered by government initiatives, private investment, and an entrepreneurial ecosystem, are advancing a new wave of automotive manufacturing that emphasizes innovation. The Department of Energy’s investments in clean energy manufacturing and the Commerce Department’s focus on resilient supply chains symbolize institutional commitment to maintaining U.S. leadership in this space.

Private sector collaborations, such as partnerships between OEMs and specialty foundries, foster shared technological development, especially in lightweight alloys, additive manufacturing, and EV-specific materials. These efforts position the United States to sustain a pioneering edge well into the next decades of automotive evolution.

| Relevant Category | Substantive Data |

|---|---|

| Carbon Reduction | Target to reduce manufacturing-related emissions by 50% by 2030 as part of national climate goals |

| R&D Investment | $2.5 billion allocated annually to advanced materials and sustainable manufacturing in the U.S. economy |

| Technological Innovation | Over 100 new patents annually relating to automotive casting and manufacturing processes registered in the U.S. |

Conclusion: The Road Ahead for American Car and Foundry Innovation

The intertwined histories of American car manufacturing and foundry industries illustrate a remarkable narrative of technological resilience and visionary adaptation. As the industry navigates the twin challenges of electrification and digital transformation, the foundational role of advanced foundry services remains pivotal. Moving forward, continued investments in materials science, green manufacturing practices, and Industry 4.0 technologies will reinforce America’s position as a global leader in automotive innovation.

This synergy of sectors—rooted in decades of shared evolution—demonstrates how American manufacturing can sustain its pioneering edge by embracing future-oriented strategies while honoring its industrial heritage. The ongoing dance between innovation and tradition promises to uphold the U.S. automotive and foundry industries as key drivers of economic growth, technological progress, and sustainable development in the decades to come.

How have American foundries contributed to automotive innovation historically?

+American foundries historically supplied high-precision casting components vital for the development of early automobiles. By advancing techniques like sand casting and die casting, they enabled the mass production of lightweight, durable parts. Their collaboration with automakers led to innovations such as aluminum engine blocks and complex chassis components, laying a technical foundation for automotive evolution.

What role does material science play in modern automotive casting advancements?

+Material science drives the development of high-performance alloys tailored for high-temperature, corrosion-resistant, and lightweight applications. Innovations like silicon carbide-reinforced castings enable safer, more efficient electric vehicle components. These advances directly impact vehicle performance, sustainability, and longevity.

How is Industry 4.0 transforming foundry operations?

+The integration of IoT sensors, AI analytics, and digital twin models creates smarter, more agile foundries. These technologies enhance process control, reduce waste, optimize energy use, and enable rapid prototyping. As a result, American foundries are increasingly able to meet the dynamic demands of modern automotive manufacturing efficiently.

What are the future prospects for sustainability within American automotive manufacturing?

+Future sustainable manufacturing will rely on recycling metals, adopting renewable energy, and utilizing environmentally friendly casting techniques. Innovations in metals processing and waste reduction aim to cut emissions by half by 2030, aligning industry practices with global climate commitments and ensuring long-term competitiveness.

How do policy developments influence innovation in American car and foundry sectors?

+Government initiatives like R&D funding, emissions regulations, and resilience programs provide incentives and support for technological development. This policy environment encourages private investments and innovation collaborations, positioning the U.S. as a leader in clean, smart, and sustainable automotive manufacturing.