Cement curing time is a critical factor in the construction process, as it directly affects the strength, durability, and overall quality of the finished product. Whether you're a seasoned contractor or a DIY enthusiast, understanding the importance of proper cement curing is essential for achieving professional-grade results. In this article, we'll delve into the world of cement curing, exploring the factors that influence curing time, the different methods of curing, and the benefits of proper curing techniques.

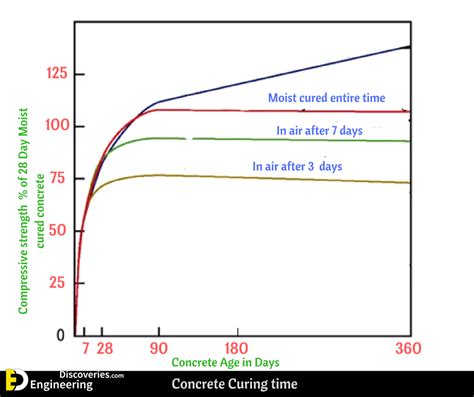

The curing process begins as soon as the cement is mixed with water, and it can take anywhere from a few days to several weeks for the concrete to reach its full strength. The American Concrete Institute (ACI) recommends a minimum curing period of 7 days for most concrete applications, but this can vary depending on the specific type of cement, ambient temperature, and humidity levels. For example, high-strength concrete may require a longer curing period, typically ranging from 14 to 28 days, to achieve its full potential. On the other hand, rapid-set cement can be cured in as little as 24 hours, making it an ideal choice for time-sensitive projects.

Key Points

- The curing process begins as soon as the cement is mixed with water

- Minimum curing period: 7 days (ACI recommendation)

- Curing time varies depending on cement type, temperature, and humidity

- High-strength concrete requires longer curing periods (14-28 days)

- Rapid-set cement can be cured in as little as 24 hours

Curing Methods and Techniques

There are several methods of curing concrete, each with its own advantages and disadvantages. The most common methods include water curing, membrane curing, and steam curing. Water curing involves applying a layer of water to the surface of the concrete, either by spraying or flooding, to maintain a consistent level of moisture. Membrane curing, on the other hand, involves applying a specialized membrane to the surface of the concrete to prevent moisture loss. Steam curing is a more advanced method that involves using steam to accelerate the curing process, often used in precast concrete applications.

Curing Time Factors

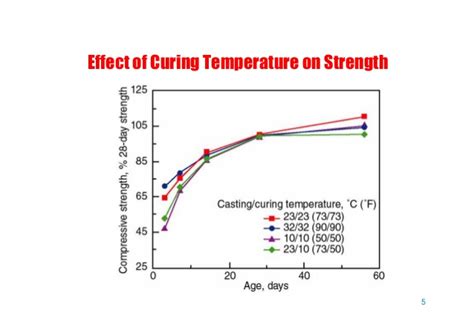

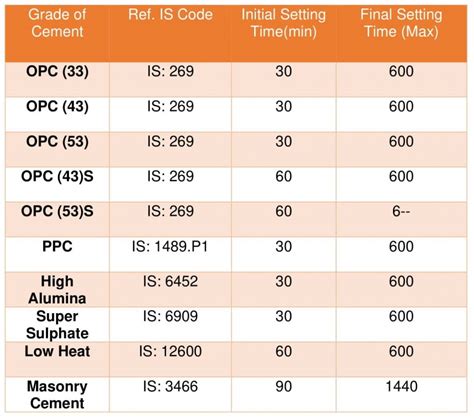

Several factors can influence the curing time of concrete, including temperature, humidity, and cement type. Ambient temperature plays a significant role in the curing process, as high temperatures can accelerate the reaction between the cement and water, while low temperatures can slow it down. Humidity levels also affect the curing process, as low humidity can lead to rapid moisture loss and reduced curing efficiency. The type of cement used can also impact curing time, with rapid-set cement requiring shorter curing periods than standard cement.

| Cement Type | Curing Time | Temperature Range |

|---|---|---|

| Standard Cement | 7-14 days | 50°F - 90°F (10°C - 32°C) |

| High-Strength Cement | 14-28 days | 50°F - 90°F (10°C - 32°C) |

| Rapid-Set Cement | 24 hours - 3 days | 50°F - 90°F (10°C - 32°C) |

Benefits of Proper Curing

Proper curing techniques offer numerous benefits, including increased strength, improved durability, and reduced maintenance costs. By maintaining a consistent level of moisture during the curing process, concrete is able to develop its full potential, resulting in a stronger and more durable finished product. Additionally, proper curing can help to reduce the risk of cracking and improve the overall appearance of the concrete. In the long run, proper curing techniques can save time and money by reducing the need for costly repairs and maintenance.

Curing Time Implications

The implications of curing time on the construction process cannot be overstated. Inadequate curing can lead to a range of problems, including reduced strength, increased porosity, and a higher risk of cracking. On the other hand, proper curing can result in a stronger, more durable, and more aesthetically pleasing finished product. As the construction industry continues to evolve, it’s essential that contractors and DIYers prioritize proper curing techniques to ensure that their projects meet the highest standards of quality and safety.

What is the minimum curing period for most concrete applications?

+The minimum curing period for most concrete applications is 7 days, as recommended by the American Concrete Institute (ACI).

How does temperature affect the curing process?

+Temperature plays a significant role in the curing process, as high temperatures can accelerate the reaction between the cement and water, while low temperatures can slow it down.

What are the benefits of proper curing techniques?

+Proper curing techniques offer numerous benefits, including increased strength, improved durability, and reduced maintenance costs.

In conclusion, cement curing time is a critical factor in the construction process, and understanding the factors that influence curing time is essential for achieving professional-grade results. By using the right curing methods and techniques, contractors and DIYers can ensure that their projects meet the highest standards of quality and safety. Whether you’re working on a small DIY project or a large-scale construction site, proper curing techniques can make all the difference in the long run.