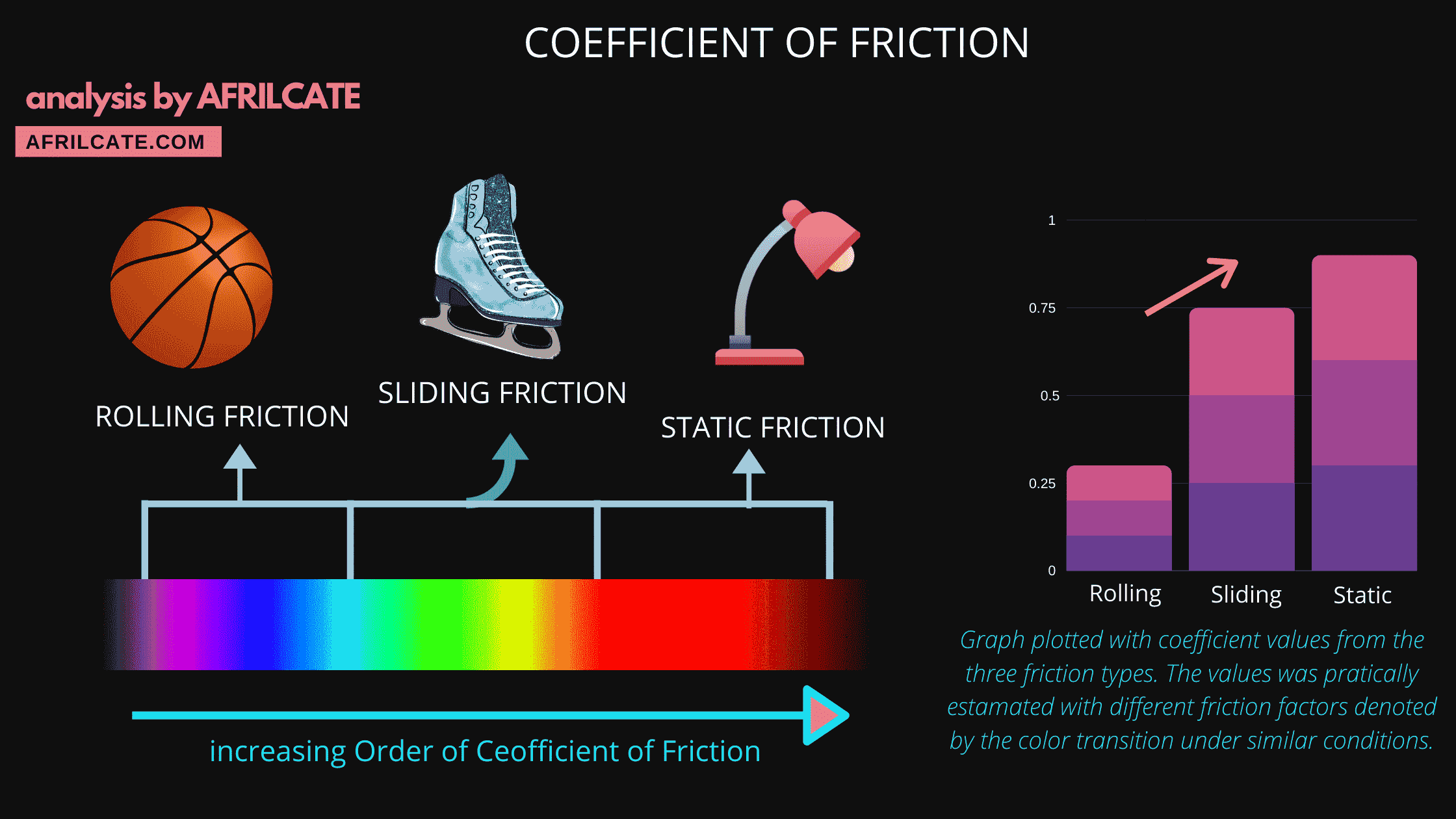

The kinetic friction coefficient is a fundamental concept in physics and engineering, playing a crucial role in understanding the behavior of objects in motion. It is a measure of the resistance that an object encounters when it is moving over a surface, and it is a key factor in determining the force required to keep an object moving at a constant velocity. In this article, we will delve into the world of kinetic friction, exploring its definition, calculation, and practical applications.

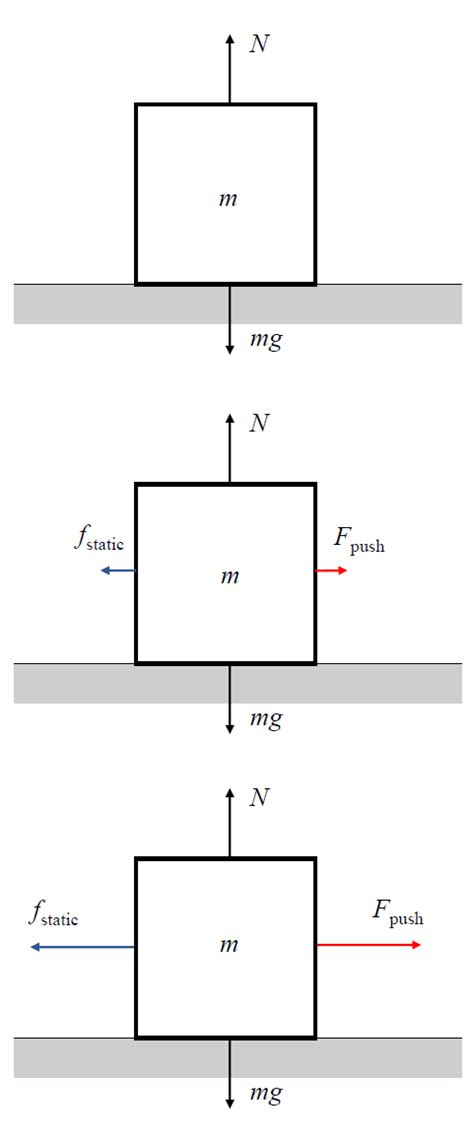

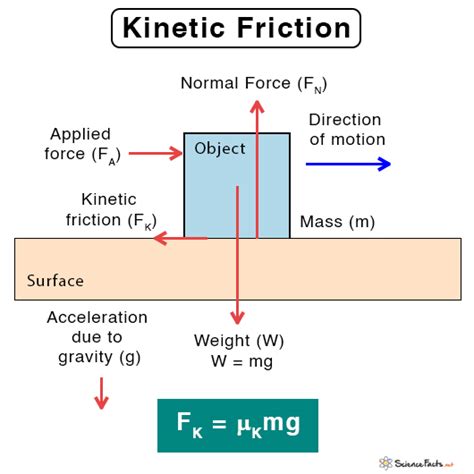

To begin with, let's define what kinetic friction is. Kinetic friction, also known as dynamic friction, is the force that opposes the motion of an object that is already in motion. It is the force that acts in the opposite direction of the motion, trying to slow down the object. The kinetic friction coefficient, often denoted by the Greek letter μ (mu), is a dimensionless quantity that represents the ratio of the kinetic friction force to the normal force acting on the object. The normal force is the force exerted by the surface on the object, perpendicular to the surface.

Key Points

- The kinetic friction coefficient is a measure of the resistance an object encounters when moving over a surface.

- It is calculated as the ratio of the kinetic friction force to the normal force acting on the object.

- The kinetic friction coefficient depends on the materials of the two surfaces in contact and the condition of the surfaces.

- It is an important factor in determining the force required to keep an object moving at a constant velocity.

- Understanding kinetic friction is crucial in various fields, including engineering, physics, and materials science.

Calculation of Kinetic Friction Coefficient

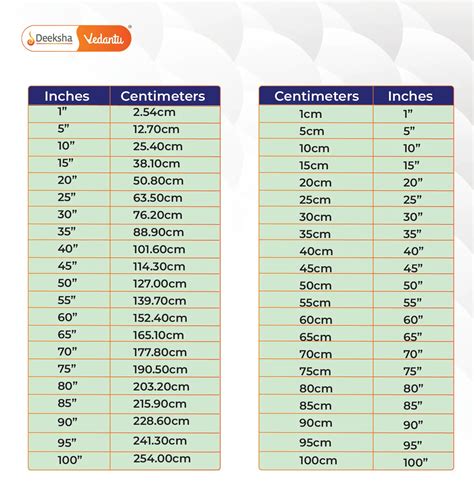

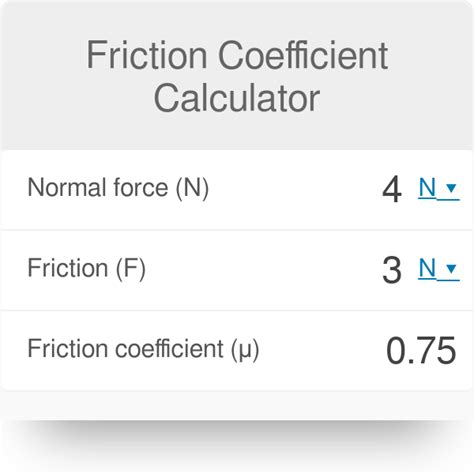

The calculation of the kinetic friction coefficient is straightforward. It is given by the formula: μ = F_k / F_n, where F_k is the kinetic friction force and F_n is the normal force. The kinetic friction force can be measured using various techniques, such as using a spring scale or a force sensor. The normal force can be calculated using the formula: F_n = m * g, where m is the mass of the object and g is the acceleration due to gravity.

For example, consider a block of wood sliding over a concrete surface. If the mass of the block is 10 kg and the acceleration due to gravity is 9.8 m/s^2, the normal force acting on the block is 10 kg \* 9.8 m/s^2 = 98 N. If the kinetic friction force is measured to be 20 N, the kinetic friction coefficient can be calculated as: μ = 20 N / 98 N = 0.2.

Factors Affecting Kinetic Friction Coefficient

The kinetic friction coefficient depends on several factors, including the materials of the two surfaces in contact and the condition of the surfaces. For example, the kinetic friction coefficient between two smooth surfaces, such as glass and metal, is typically lower than that between two rough surfaces, such as wood and concrete. Additionally, the kinetic friction coefficient can be affected by the presence of lubricants or other substances on the surfaces.

| Material Combination | Kinetic Friction Coefficient |

|---|---|

| Steel on Steel | 0.1-0.2 |

| Wood on Concrete | 0.4-0.6 |

| Rubber on Asphalt | 0.6-0.8 |

Practical Applications of Kinetic Friction Coefficient

Understanding the kinetic friction coefficient is crucial in various fields, including engineering, physics, and materials science. It is used to design and optimize systems that involve moving parts, such as gears, bearings, and brakes. For example, in the design of a car brake system, the kinetic friction coefficient is used to determine the force required to stop the car within a certain distance.

In addition, the kinetic friction coefficient is used in the development of new materials and surface treatments. For example, researchers are working on developing new materials with low kinetic friction coefficients, such as self-lubricating materials, to reduce energy consumption and improve efficiency in various applications.

Real-World Examples

Kinetic friction is all around us, and its effects can be seen in various real-world examples. For instance, when you try to push a heavy box across the floor, you may notice that it is harder to get it moving than to keep it moving. This is because the static friction force, which opposes the motion when the object is at rest, is greater than the kinetic friction force, which opposes the motion when the object is moving.

Another example is the use of kinetic friction in the design of roller coasters. The kinetic friction coefficient is used to determine the force required to keep the roller coaster cars moving at a constant velocity, and to design the braking system to safely slow down the cars.

What is the difference between static and kinetic friction?

+Static friction is the force that opposes the motion of an object when it is at rest, while kinetic friction is the force that opposes the motion of an object when it is already moving.

How is the kinetic friction coefficient calculated?

+The kinetic friction coefficient is calculated as the ratio of the kinetic friction force to the normal force acting on the object.

What are some real-world examples of kinetic friction?

+Kinetic friction can be seen in various real-world examples, such as the design of car brake systems, roller coasters, and the development of new materials and surface treatments.

In conclusion, the kinetic friction coefficient is a fundamental concept in physics and engineering, playing a crucial role in understanding the behavior of objects in motion. Its calculation, factors affecting it, and practical applications make it a vital aspect of designing and optimizing systems that involve moving parts. By understanding the kinetic friction coefficient, we can improve the efficiency and safety of various systems, from car brake systems to roller coasters, and develop new materials and technologies that reduce energy consumption and improve performance.