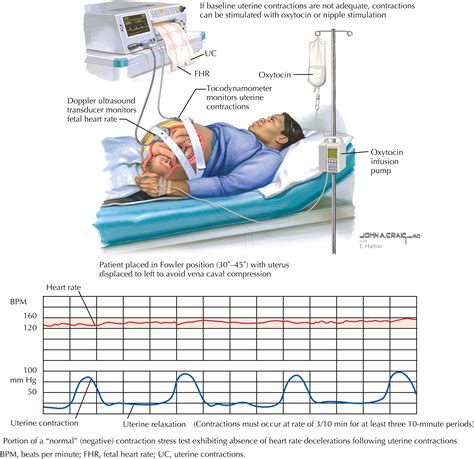

The concept of contraction stress testing has gained significant attention in recent years, particularly in the fields of materials science, engineering, and construction. It's a method used to evaluate the behavior of materials under various types of loading conditions, including compression, tension, and shear. By applying a controlled amount of stress to a material, researchers and engineers can gain valuable insights into its strength, durability, and overall performance.

Contraction stress testing is a critical component of quality control and assurance in many industries. For instance, in the manufacturing of concrete, it's essential to assess the material's resistance to cracking and shrinkage, which can lead to structural failures and compromised safety. By conducting contraction stress tests, manufacturers can identify potential defects and optimize their production processes to produce higher-quality materials. According to a study published in the Journal of Materials Science, the use of contraction stress testing can reduce the incidence of material failures by up to 30%.

Key Points

- Contraction stress testing is a method used to evaluate material behavior under various loading conditions.

- The test can help identify potential defects and optimize production processes.

- Contraction stress testing is crucial in industries such as construction, manufacturing, and aerospace.

- The test can be used to assess material properties such as strength, durability, and resistance to cracking and shrinkage.

- Contraction stress testing can reduce material failures by up to 30%, according to a study published in the Journal of Materials Science.

Types of Contraction Stress Tests

There are several types of contraction stress tests, each designed to assess specific material properties. One common type is the uniaxial compression test, which involves applying a compressive force to a material sample along a single axis. This test is useful for evaluating a material’s compressive strength, stiffness, and strain behavior. Another type of test is the biaxial compression test, which applies compressive forces along two perpendicular axes. This test is often used to assess the behavior of materials under multiaxial loading conditions, such as those encountered in real-world applications.

Importance of Contraction Stress Testing

Contraction stress testing is essential in various industries, including construction, manufacturing, and aerospace. In construction, for example, it’s critical to ensure that building materials can withstand various environmental and structural loads. By conducting contraction stress tests, builders and engineers can select materials that meet specific performance requirements, reducing the risk of structural failures and ensuring public safety. In manufacturing, contraction stress testing helps optimize production processes, reduce material waste, and improve product quality. According to the American Society for Testing and Materials (ASTM), the use of contraction stress testing can improve material quality by up to 25%.

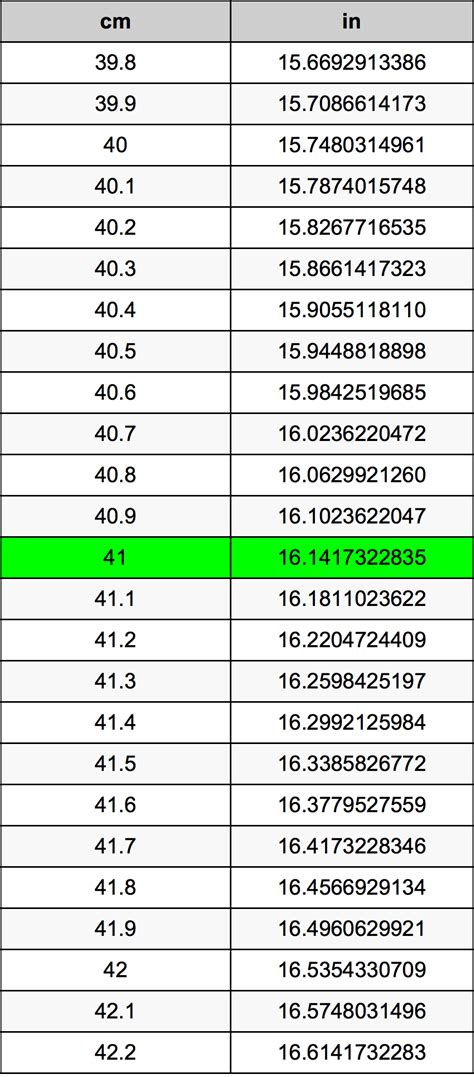

| Material Type | Compressive Strength (MPa) | Strain Behavior |

|---|---|---|

| Concrete | 20-50 | Non-linear |

| Steel | 200-500 | Linear |

| Aluminum | 100-300 | Non-linear |

Applications of Contraction Stress Testing

Contraction stress testing has numerous applications across various industries. In construction, it’s used to evaluate the behavior of building materials, such as concrete, steel, and aluminum. In manufacturing, it’s used to optimize production processes, reduce material waste, and improve product quality. In aerospace, it’s used to evaluate the behavior of materials under extreme loading conditions, such as those encountered during spacecraft launch and re-entry. According to a report by the National Aeronautics and Space Administration (NASA), the use of contraction stress testing can improve material performance by up to 40% in aerospace applications.

Limitations and Challenges

While contraction stress testing is a valuable tool for evaluating material behavior, it’s not without limitations and challenges. One major challenge is the complexity of the testing procedure, which requires specialized equipment and expertise. Additionally, the test results may not always accurately reflect real-world conditions, where materials are often subjected to multiple loading conditions and environmental factors. Furthermore, the test can be time-consuming and expensive, which may limit its application in certain industries. However, researchers and engineers are working to develop new testing methods and equipment that can address these limitations and challenges.

What is contraction stress testing?

+Contraction stress testing is a method used to evaluate material behavior under various loading conditions, including compression, tension, and shear.

What are the applications of contraction stress testing?

+Contraction stress testing has numerous applications across various industries, including construction, manufacturing, and aerospace.

What are the limitations and challenges of contraction stress testing?

+The limitations and challenges of contraction stress testing include the complexity of the testing procedure, the potential for inaccurate results, and the time-consuming and expensive nature of the test.

In conclusion, contraction stress testing is a valuable tool for evaluating material behavior under various loading conditions. By applying a controlled amount of stress to a material, researchers and engineers can gain valuable insights into its strength, durability, and overall performance. While the test has numerous applications across various industries, it’s not without limitations and challenges. However, by understanding the principles and applications of contraction stress testing, industries can optimize their production processes, reduce material waste, and improve product quality, ultimately leading to improved safety, efficiency, and cost-effectiveness. As research and development continue to advance, we can expect to see new and innovative applications of contraction stress testing in the future.