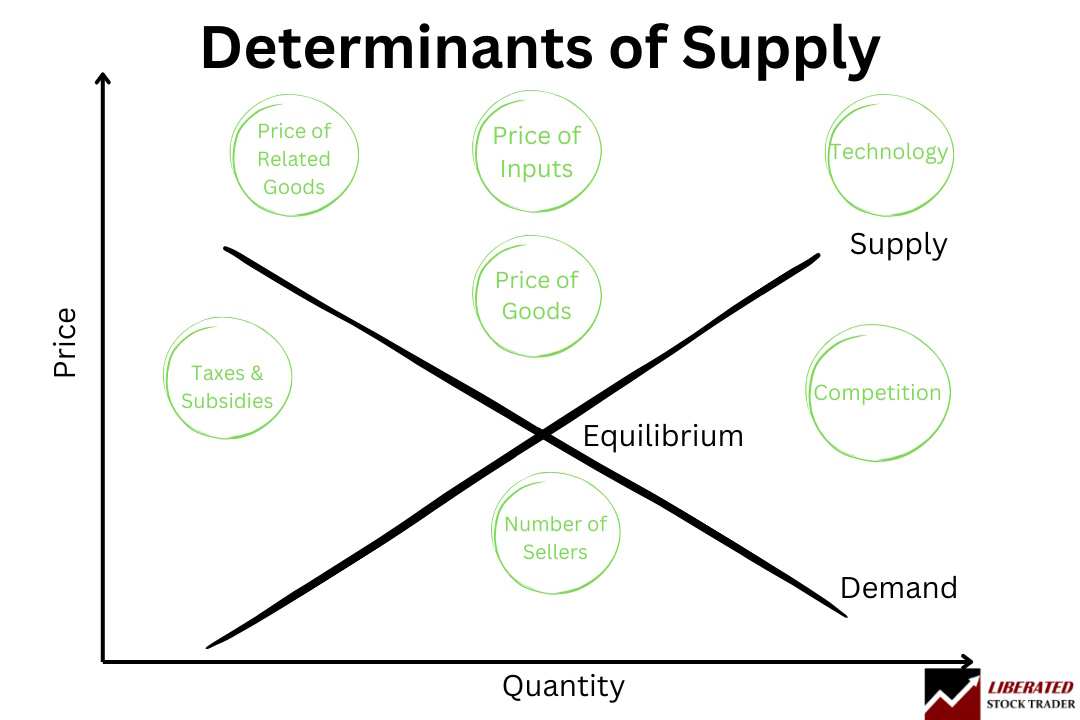

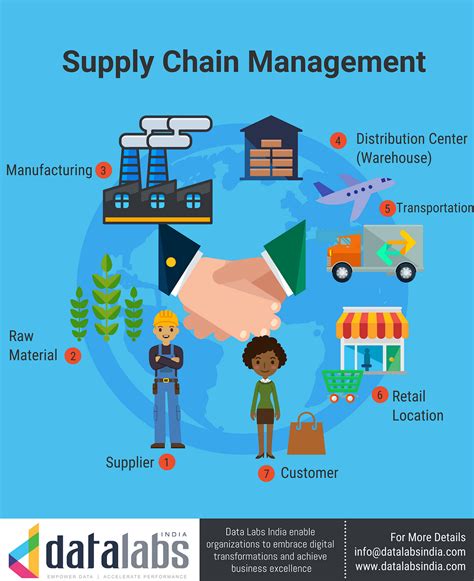

The concept of determinants in supply chain management is multifaceted and plays a crucial role in the overall efficiency and effectiveness of an organization's operations. At its core, supply chain management involves the coordination and management of activities across the entire supply chain, from sourcing raw materials to delivering products to end customers. Determinants, in this context, refer to the factors that influence the design, implementation, and performance of supply chain strategies. Understanding these determinants is essential for companies seeking to optimize their supply chains, reduce costs, enhance customer satisfaction, and ultimately gain a competitive edge in the market.

One of the primary determinants in supply chain management is demand variability. The ability to accurately forecast demand is critical because it directly affects inventory levels, production planning, and logistics operations. Companies that can better predict demand fluctuations are in a stronger position to manage their supply chains efficiently, minimizing the risks of overstocking or understocking. This is particularly challenging in industries with seasonal demand patterns or where product life cycles are short. Demand forecasting techniques, including statistical models and machine learning algorithms, are increasingly being employed to improve the accuracy of demand predictions.

Key Determinants in Supply Chain Management

Beyond demand variability, several other determinants significantly impact supply chain management. These include supplier reliability, transportation infrastructure, inventory management practices, and information technology integration. Each of these factors can either enhance or hinder the performance of a supply chain, depending on how they are managed. For instance, a reliable supplier can ensure consistent and high-quality supply of raw materials, while an unreliable one can lead to stockouts and delays. Similarly, the efficiency of transportation infrastructure can significantly affect the speed and cost of moving goods from one point to another.

Role of Information Technology

Information technology (IT) plays a pivotal role in modern supply chain management. Supply chain visibility, which refers to the ability to track products and components in real-time throughout the supply chain, is a key determinant of supply chain efficiency. Technologies such as blockchain, Internet of Things (IoT), and cloud computing are being increasingly adopted to enhance visibility, improve data sharing among partners, and automate various supply chain processes. For example, blockchain technology can help in ensuring the authenticity and traceability of products, reducing counterfeiting and improving quality control.

| Technology | Application in Supply Chain Management |

|---|---|

| Blockchain | Enhancing supply chain transparency and security |

| IoT | Real-time tracking and monitoring of shipments |

| Cloud Computing | Scalable and flexible data management and analysis |

Key Points

- Demand variability is a critical determinant that affects inventory management and production planning in supply chain management.

- Supplier reliability and transportation infrastructure are external determinants that can significantly impact supply chain performance.

- Information technology, including blockchain, IoT, and cloud computing, is crucial for enhancing supply chain visibility, security, and efficiency.

- The effective integration of technology requires not only the adoption of new systems but also changes in business processes and employee training.

- Supply chain management determinants are interconnected, and managing them requires a holistic and strategic approach.

Another crucial aspect of supply chain management is risk management. Supply chains are inherently vulnerable to various risks, including natural disasters, supplier insolvency, and geopolitical events. Companies must develop robust risk management strategies to mitigate these risks, including diversifying their supplier base, developing contingency plans, and investing in supply chain insurance. The COVID-19 pandemic, for example, highlighted the importance of supply chain resilience and the need for companies to have plans in place to manage disruptions.

In conclusion, the determinants in supply chain management are complex and multifaceted, requiring a deep understanding of both internal and external factors that influence supply chain performance. By focusing on demand variability, supplier reliability, transportation infrastructure, inventory management, information technology integration, and risk management, companies can develop more resilient and efficient supply chains. This not only enhances their competitive advantage but also contributes to better customer service and profitability.

What are the primary determinants of supply chain management?

+The primary determinants include demand variability, supplier reliability, transportation infrastructure, inventory management practices, and information technology integration. Each of these factors plays a significant role in the efficiency and effectiveness of supply chain operations.

How does information technology impact supply chain management?

+Information technology enhances supply chain visibility, security, and efficiency. Technologies like blockchain, IoT, and cloud computing are used for real-time tracking, data sharing, and process automation, leading to better decision-making and reduced risks.

Why is risk management important in supply chain management?

+Risk management is crucial because supply chains are vulnerable to various risks such as natural disasters, supplier insolvency, and geopolitical events. Effective risk management strategies, including diversification and contingency planning, can help mitigate these risks and ensure supply chain resilience.