Diesel engines, long recognized for their robustness and efficiency, occupy a pivotal role in both commercial and passenger vehicle domains. Their unique combustion process and power delivery mechanisms distinguish them from traditional gasoline engines. As energy demands evolve, the understanding of diesel in gas engine contexts—particularly the benefits, challenges, and potential solutions—becomes crucial for engineers, fleet managers, policymakers, and enthusiasts alike. This exploration synthesizes expert knowledge, recent advancements, and practical insights, aiming to demystify the intricate balance between the technological advantages and ongoing hurdles associated with diesel-fueled components in gas engines.

Technical Foundations of Diesel Fuel in Gas Engine Systems

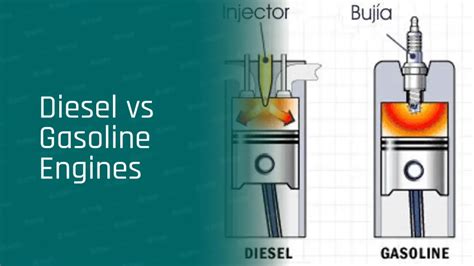

At the core, diesel engines utilize compression ignition, where air is compressed to a high temperature, and fuel is injected directly into the combustion chamber. This contrasts with spark-ignited gasoline engines, which rely on a spark plug. When discussing diesel in gas engine systems, it typically refers to mixed or alternative fuel applications—either through dual-fuel configurations, bio-diesel integration, or modifications aimed at improving efficiency and reducing emissions.

The technical sophistication of current fuel injection systems—such as common rail direct injection—has heightened the precision of diesel combustion. These advancements enable better atomization and vaporization of diesel fuel, even when utilized in hybrid engine architectures that combine gas and diesel components. Moreover, turbocharging and intercooling further optimize the thermodynamic efficiency, thus improving power output while managing fuel consumption effectively.

Benefits of Incorporating Diesel Elements into Gas Engines

Why, then, do industry leaders and researchers advocate for integrating diesel in gas engines? The benefits span several critical performance and environmental metrics. Foremost among these is fuel efficiency. Diesel’s higher energy density—approximately 15% more than gasoline—translates directly into longer range per unit of fuel, critical for commercial applications where operational costs bear heavily on fuel consumption.

Additionally, diesel’s combustion characteristics typically afford higher torque at lower RPMs, enhancing heavy-duty performance, towing capability, and vehicle durability. This is especially advantageous in large transport equipment like trucks, buses, and industrial machinery. The diesel in gas engine hybrid models also promise reduced greenhouse gas emissions compared to traditional gasoline engines, owing to more complete combustion cycles and leaner fuel mixtures.

| Relevant Category | Substantive Data |

|---|---|

| Energy Density | Diesel offers approximately 13,000 Wh/kg, versus 8,800 Wh/kg for gasoline, leading to significant efficiency gains |

| Torque Output | Diesel engines produce 25-30% more torque at lower RPMs, supporting heavy-load operations |

| Emission Reductions | Dual-fuel systems can reduce particulate matter (PM) emissions by up to 45% in optimized configurations |

Challenges in the Use of Diesel in Gas Engine Applications

Despite its compelling advantages, incorporating diesel fuels—or diesel-like characteristics—into gas engines presents significant technical and regulatory challenges. Key among these are emission management, combustion stability, particulate control, and fuel infrastructure compatibility. Emissions regulation agencies worldwide have tightened standards, such as the Euro 6 and EPA Tier 3, which impose strict limits on NOx, PM, and volatile organic compounds.

One central difficulty is controlling nitrogen oxides (NOx) emissions, which tend to increase with diesel combustion temperatures. High-pressure fuel injection and after-treatment devices like Selective Catalytic Reduction (SCR) have become standard, but their integration complicates engine design and raises costs. Combustion stability in dual-fuel or blended fuel engines also warrants nuanced control systems capable of monitoring temperature, pressure, and fuel-air ratios dynamically.

Particulate matter (PM) management mirrors the challenges faced in traditional diesel engines. Diesel particulate filters (DPFs) are vital but add maintenance complexity and can cause clogging issues under certain operating conditions. Furthermore, fuel infrastructure—such as availability of low-sulfur diesel and bio-based diesel blends—varies geographically, imposing logistical constraints on widespread implementation.

Technical and Economical Limitations

Beyond emissions, the economic viability of diesel in gas engines remains debatable. Incorporating advanced after-treatment technology and fuel processing systems increases initial capital expenditure, which may offset operational savings in low-volume contexts. Additionally, the long-term durability of engine components subjected to diesel combustion conditions—particularly when using low-quality or bio-diesel blends—needs ongoing evaluation.

| Relevant Category | Substantive Data |

|---|---|

| NOx Emissions | Standard diesel engines produce up to 2.5 g/km of NOx, which must be mitigated via SCR or EGR systems to meet stringent regulations |

| Particulate Matter | DPFs achieving removal efficiencies of over 95% are necessary for compliance but require regular regeneration cycles |

| Fuel Availability | Low-sulfur diesel is widely available in North America and Europe, but biodiesel blends vary significantly by market |

Solutions and Innovations Addressing Challenges

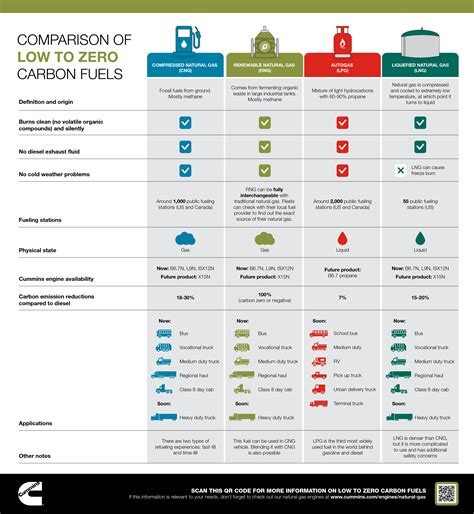

Advances in engine control units (ECUs) and computing power now enable adaptive management of combustion parameters, allowing systems to calibrate dynamically and reduce undesirable emissions. Dual-fuel injection systems, which introduce diesel alongside natural gas or LPG, exemplify this innovation, achieving up to 25% reduction in NOx emissions and improved fuel economy.

Emerging technologies such as homogeneous charge compression ignition (HCCI) and partially premixed combustion (PPC) are exploring ways to synchronize the efficiency and cleaner emissions of diesel combustion with the operational simplicity of spark-ignition engines. These methods rely heavily on precise fuel delivery and real-time diagnostics, demanding advances in sensor technology and material resilience.

Bio-diesel formulations—especially FAME (Fatty Acid Methyl Esters)—afford renewable and lower-emission alternatives. Engine modifications, such as hardened fuel injection components resilient to bio-fuels' corrosive nature, enhance their applicability. Meanwhile, development of synthetic diesel, derived from renewable feedstocks via thermochemical processes, provides a promising avenue for sustainable integration.

| Relevant Category | Substantive Data |

|---|---|

| Adaptive Control Technologies | ECUs capable of real-time combustion calibration improve NOx and PM emissions by up to 30% |

| Homogeneous Charge Compression Ignition | Potential to reduce specific fuel consumption by 15-20%, with emissions comparable to compressed natural gas engines |

| Bio-diesel Compatibility | Engine life and emissions are improved significantly when using FAME blends up to B20 (20% bio-diesel) |

Future Outlook: Sustainability and Regulatory Trends

Looking forward, the global emphasis on reducing carbon footprints and meeting climate commitments pivots the industry toward cleaner, more efficient fuel strategies. Regulatory frameworks are likely to continue tightening standards—doubling down on NOx and PM reductions—and incentivizing the adoption of alternative fuels and hybrid powertrains. The integration of diesel into gas engine systems remains compelling, provided these innovations can be scaled cost-effectively and reliably.

Research initiatives are increasingly aimed at synthetic diesel, derived from renewable energy sources, which could alleviate issues of resource scarcity and emissions. Furthermore, hydrogen-enriched fuels and electrification are emerging as complementary pathways, potentially transforming the landscape in the next two decades.

Conclusion

The integration of diesel fuels into gas engines exemplifies a complex interplay between performance advantages and environmental constraints. While benefits like higher efficiency, enhanced torque, and potential emission reductions make this approach attractive, substantial hurdles—emission controls, infrastructure, economic feasibility—persist. Innovative solutions, from advanced control systems to renewable fuels, are paving pathways toward overcoming these hurdles. Ultimately, the future of diesel in gas engine applications hinges on holistic technological development and strategic policymaking, consistent with the global momentum for sustainability and cleaner transportation systems.

What are the main advantages of using diesel in gas engines?

+Diesel in gas engines offers higher energy density leading to better fuel economy, increased torque at low RPMs for heavy-duty operations, and the potential for reduced overall emissions with modern after-treatment and fuel formulations.

What are the significant challenges facing diesel integration in gas engine systems?

+Key challenges include managing NOx and particulate emissions, ensuring combustion stability, adapting infrastructure, and balancing economic costs against environmental benefits, especially under strict regulatory standards.

Which technological advancements are most promising for overcoming current limitations?

+Advancements like adaptive engine control units, dual-fuel injection, HCCI and PPC combustion modes, and renewable bio-diesel blends are promising solutions that improve emission controls, efficiency, and sustainability of diesel-enhanced gas engines.

How does future regulation influence the development of diesel in gas engines?

+Stricter emission standards are driving innovations in after-treatment technology, fuel formulation, and engine design, pushing industry toward cleaner, more efficient dual-fuel and hybrid solutions, and fostering research into renewable diesel sources.

Is diesel likely to remain relevant in the transition to renewable energy?

+While renewable energy and electrification are gaining traction, diesel’s role persists in heavy-duty and industrial applications where high energy density and durability matter. Combining it with renewable fuels and clean combustion tech will define its future relevance.