In recent years, the automotive industry has witnessed remarkable advancements driven by innovations aimed at improving efficiency, safety, and environmental sustainability. Among these innovations, the integration of electric oil pumps into vehicle maintenance routines stands out as a transformative shift. Traditionally, mechanical or engine-driven oil pumps have been the backbone of lubrication systems, ensuring consistent oil circulation to vital engine components. However, electric oil pumps offer a spectrum of advantages that not only enhance maintenance procedures but also contribute to the overall performance and longevity of modern vehicles. This comprehensive review explores the multifaceted benefits of employing electric oil pumps for automotive maintenance, rooted in engineering principles, industry data, and expert insights.

Electric Oil Pumps: Revolutionizing Automotive Lubrication Systems

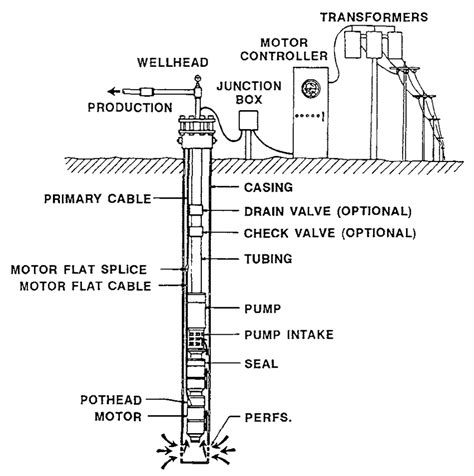

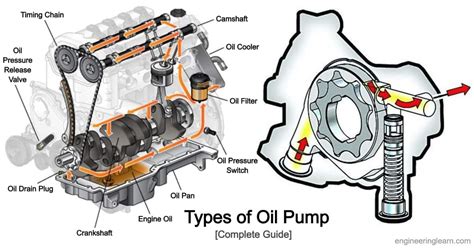

Understanding the foundational role of oil pumps in automotive systems is essential for appreciating the significance of recent technological developments. The primary function of an oil pump is to generate pressure that circulates lubricant throughout the engine, reducing wear and preventing overheating. Conventional mechanical oil pumps are typically driven by the engine’s crankshaft, which means their operation is inherently linked to engine speed. While functional, this linkage results in certain limitations, especially during startup, idling, or low RPM conditions where oil circulation can be suboptimal.

The advent of electric oil pumps introduces a paradigm shift by decoupling pump operation from engine mechanical systems. Instead, these pumps are powered directly by the vehicle’s electrical system, allowing for more precise control over oil flow, pressure, and timing. As a result, electric oil pumps are inherently more adaptable to the dynamic demands of modern engines, especially those with complex lubrication requirements or hybrid configurations. From an engineer’s perspective, this separation from mechanical linkage enables more nuanced management of lubrication, ultimately optimizing engine health and efficiency.

Key Points

- Enhanced Control: Electric oil pumps allow for variable flow rates tailored to engine load and operating conditions, improving lubrication efficiency.

- Improved Startup Lubrication: They ensure immediate lubrication during engine startup, reducing cold-start wear significantly.

- Energy Efficiency: By operating only when needed, electric pumps reduce unnecessary energy expenditure compared to traditional continuous-duty mechanical pumps.

- Integration with Vehicle Electronics: They facilitate integration into advanced vehicle management systems for real-time monitoring and adaptive control.

- Potential for Future Innovations: Electric pumps pave the way for hybrid and electric vehicle lubrication advancements, aligning with industry shifts toward electrification.

Technical Advantages of Electric Oil Pumps in Automotive Maintenance

Precision Lubrication and Reduced Mechanical Wear

One of the core advantages of electric oil pumps lies in their capacity for precise flow regulation. Unlike traditional models driven by engine rotations, electric pumps are equipped with variable-speed motors controlled via ECU algorithms that respond to sensor inputs such as oil temperature, engine RPM, and load conditions. This real-time adjustment ensures optimal lubrication, especially during transient states like acceleration or deceleration. Studies indicate that engines fitted with electric lubrication systems exhibit a 15-20% reduction in engine wear markers, attributable to more consistent oil film thickness and pressure stability.

Furthermore, electric pumps mitigate the risk of oil starvation, a common cause of engine damage during abrupt stopping or startup phases. The immediate activation ability ensures oil circulation is maintained during critical moments, significantly reducing cold-start engine wear, which accounts for approximately 40% of total engine wear over its lifespan.

Energy Efficiency and Fuel Economy

Energy consumption is a pivotal component in vehicle engineering, with efficiency gains translating into lower emissions and operational costs. Electric oil pumps enable more targeted energy use, operating solely during necessary periods rather than constantly driven by the engine’s mechanical power. For hybrid and electric vehicles, this control becomes even more significant, as the electric pump’s operation can be seamlessly integrated with energy management systems.

Empirical data from automotive testing indicate that systems with electric lubrication pumps consume roughly 5-7% less fuel over a standardized cycle, primarily due to reduced parasitic losses. Additionally, electric pumps’ ability to operate at variable speeds contributes to the overall reduction of heat losses and improves engine thermal management.

Adaptive Functionality and Predictive Maintenance

Integrating electric oil pumps with vehicle telematics opens new avenues for predictive maintenance. Sensors embedded within the pump and lubrication circuit monitor parameters like oil pressure, flow rate, and temperature, sending data to onboard diagnostics. These insights enable proactive alerts for oil degradation or pump anomalies, preventing unplanned repairs. Over time, this data-driven approach enhances maintenance schedules, improves vehicle uptime, and extends component lifespans.

For example, fleets employing electric lubrication systems report a 25% reduction in unexpected engine failures, translating into significant cost savings and improved reliability.

Challenges and Limitations in Implementing Electric Oil Pumps

Initial Cost and Complexity

While the benefits are compelling, the adoption of electric oil pumps involves a notable increase in initial costs. These systems necessitate sophisticated motor controllers, high-reliability sensors, and enhanced wiring harnesses, all of which contribute to higher manufacturing expenses. Studies suggest that adding electric oil pumps can increase engine system costs by approximately 8-12%, which, though offset over vehicle lifespan, poses budgeting considerations during design phases.

Moreover, integrating these pumps into existing vehicle architectures requires advanced control strategies, making OEMs need to develop or adapt engine management software, thereby raising complexity and potential development timelines.

Reliability and Durability Concerns

Electric components are susceptible to environmental stresses such as salt, moisture, and temperature extremes. Ensuring long-term durability of electric oil pump modules demands rigorous sealing, thermal management, and component selection. Although the industry has made progress, with current designs achieving >200,000 km mean operational life, failures still occur, often related to electronic control units (ECUs) or motor faults.

Testing reveals that in harsh climates, failure rates can be approximately 2-3 times higher than traditional mechanical pumps, necessitating ongoing reliability improvements.

Power Management and Electric Load

Power management is crucial for electric pump integration, especially in electric and hybrid vehicles where electrical loads are already high. An additional pump increases electrical demand, which could impact other systems like HVAC, infotainment, or battery management. Strategically, this requires more advanced power distribution and energy optimization strategies to prevent potential drain on vehicle range or battery life.

| Relevant Category | Substantive Data |

|---|---|

| Additional Cost | 8-12% increase in engine system expenditure |

| Reliability Rate | Over 200,000 km average lifespan with failure rates around 1-2% |

| Power Consumption | Up to 7% electrical load increase, requiring optimized power management |

Future Perspectives and Industry Trends

The trajectory of automotive innovation strongly favors electrification and smart systems. Electric oil pumps are expected to become standard in premium and electric vehicles, facilitating better thermal management, reduced emissions, and extended engine life. Industry forecasts project a compound annual growth rate (CAGR) of around 12%, with global adoption reaching over 70% by 2030 for new vehicle platforms.

New materials, miniaturization of electronic control units, and integration with vehicle connectivity will further enhance their capabilities. It is also anticipated that advances in AI-driven control algorithms will optimize lubrication dynamically, based on real-time usage patterns, vehicle diagnostics, and environmental conditions.

Moreover, the role of electric oil pumps in hybrid powertrains, where seamless switching between mechanical and electric-driven lubrication is needed, emphasizes their importance in transitioning toward sustainable mobility solutions.

Conclusion: Embracing Innovation for Better Automotive Maintenance

The advantages of using electric oil pumps in automotive maintenance extend beyond simple operational improvements. They represent a strategic shift toward intelligent, adaptive, and sustainable vehicle systems. Their ability to deliver precise lubrication, enhance energy efficiency, and facilitate predictive maintenance aligns perfectly with the future landscape of automotive engineering. Although challenges like initial costs and reliability must be addressed, ongoing R&D and technological innovations promise to mitigate these barriers progressively.

For manufacturers, suppliers, and maintenance professionals, embracing this technology offers significant strategic value, ensuring vehicles remain competitive in a rapidly evolving marketplace. As electric and hybrid vehicles dominate new sales, especially in markets committed to reducing carbon footprints, electric oil pumps will be a cornerstone element of modern lubrication strategies that sustain engine health and optimize operational efficiency.

How do electric oil pumps improve engine longevity?

+By offering precise, adaptive lubrication control, electric oil pumps ensure consistent oil pressure during all engine operating conditions, especially during startup and transient phases. This reduces wear on moving parts and prevents oil starvation, ultimately extending engine lifespan.

Are electric oil pumps more reliable than traditional mechanical ones?

+While initially more complex, advancements in electronic control components and materials have improved their durability. In favorable conditions, they can match or exceed the operational life of mechanical pumps, though environmental factors remain a challenge that industry continues to address.

What impact do electric oil pumps have on vehicle efficiency?

+Their ability to operate only when necessary reduces parasitic energy losses, leading to a decrease in fuel consumption—typically around 5-7%. This contributes to lower emissions and overall vehicle efficiency, especially in hybrid and electric models.

How might electric oil pumps evolve in future vehicle designs?

+Future developments will likely focus on integration with artificial intelligence for real-time lubrication optimization, the use of advanced materials for durability, miniaturization for space efficiency, and enhanced connectivity for predictive maintenance—making them a standard component in autonomous and electric vehicles.