Understanding the intricacies of electrical systems begins with a fundamental comprehension of how these systems are visually represented. Among the most vital tools for this purpose is the Single Line Diagram (SLD), a simplified graphical illustration that captures the essence of complex electrical circuits with clarity and precision. For beginners delving into electrical engineering or maintenance, mastering the SLD is the first step toward designing, analyzing, and troubleshooting power systems efficiently. Historically, the evolution of electrical schematics has aimed at balancing detailed accuracy with ease of interpretation, making the single line approach an indispensable standard in electric power distribution, industrial automation, and building electrical systems. This comprehensive guide demystifies the concept of the single line diagram, elaborating on its components, conventions, and practical applications. By exploring the theoretical underpinnings, industry standards, and real-world examples, it aims to equip novices with a solid foundation and seasoned professionals with a refresher on best practices. Simply put, understanding the SLD unlocks the core language for electrical system communication—an essential skill for engineers, electricians, and facility managers alike.

Key Points

- Clarity and Simplification: The SLD abstracts complex layouts into easy-to-interpret symbols, fostering quick comprehension.

- Standardization: Widely accepted industry conventions enable consistent documentation across diverse projects.

- Critical for Troubleshooting: SLDs streamline fault isolation by highlighting key components and connections.

- Design Optimization: Facilitates efficient system planning and upgrades by providing a clear overview.

- Bridging Theory and Practice: Offers a common visual language that connects electrical theory with tangible applications.

Fundamentals of Single Line Diagrams

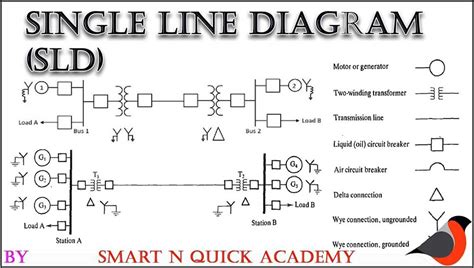

The single line diagram functions as a symbolic blueprint representing an entire electrical system with a single line—hence the name. Its primary purpose is to present the electrical flow and relationships among components such as transformers, circuit breakers, loads, and protective devices without displaying the physical wiring complexities. This abstraction allows one to analyze system performance, evaluate load distribution, and plan maintenance or modifications with minimal ambiguity.

Core Components and Symbols

The effectiveness of an SLD hinges on the standardized symbols employed to depict various electrical devices. For example, a simple rectangle with a line typically represents a transformer, while a circle or a polygon might symbolize a motor or generator. Circuit breakers are usually indicated by a specific arc or switch symbol, often with annotations to specify their ratings or trip characteristics. The consistent use of these symbols is vital for cross-disciplinary understanding, especially among engineers, electricians, and safety inspectors.

| Relevant Category | Substantive Data |

|---|---|

| Common Symbols | Transformers: double box; Circuit Breakers: a switch-like symbol with trip coil indication; Motors: circle with M; Protective Relays: a small rectangle with wave symbol |

| Color Codes | Red: Protective Devices; Green: Grounding; Blue: Control Circuits; Black: Power Lines |

| Standard References | IEEE Std 315-1975: Standard for Electrical Power System Device Symbols |

Designing an Effective Single Line Diagram

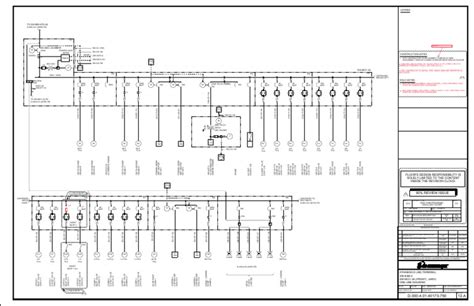

Creating a reliable SLD demands a systematic approach. First, defining the scope is crucial—whether the diagram reflects an entire industrial plant or a residential building’s electrical set-up. Next, gathering detailed specifications from system components ensures accuracy, avoiding oversimplifications that could mislead during troubleshooting or engineering modifications.

Step-by-Step Methodology

- Component Identification: Document all major electrical devices, including power sources, transformers, loads, and protective devices.

- Symbol Assignment: Use industry-standard symbols adhering to applicable codes and practices, such as IEEE or IEC standards.

- Logical Arrangement: Position components in a manner that reflects their actual or logical placement in the system, prioritizing clarity and ease of understanding.

- Connection Representation: Draw lines to indicate electrical connections, employing single lines to denote busbars, feeders, and branches efficiently.

- Annotations and Ratings: Include essential data such as voltage levels, current ratings, breaker trip ratings, and other relevant parameters.

Common Pitfalls and Best Practices

Designers must avoid cluttered diagrams that obscure critical details. Excessive crossing lines, ambiguous symbols, or omitted ratings compromise clarity. Best practices include using consistent scaling, validating the diagram through peer reviews, and updating documentation as system changes occur.

Applications and Industry Standards

Single line diagrams serve as foundational documentation in numerous sectors, including power generation, industrial plants, commercial complexes, and residential buildings. Their versatility is underscored by adherence to regulations like the National Electrical Code (NEC) in the United States or IEC standards globally. These documents become part of safety submissions, maintenance manuals, and operational protocols, reflecting industry-wide expectations for clarity and thoroughness.

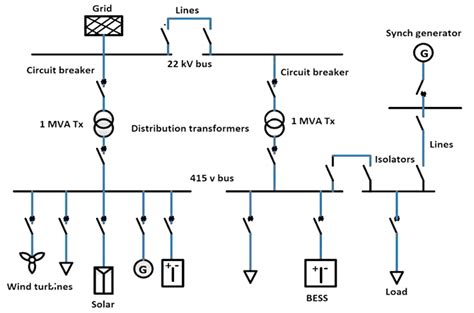

Case Study: Power Distribution in a Manufacturing Plant

Consider a manufacturing facility with multiple power sources, including a main grid supply and backup generators. The SLD demonstrates how these sources connect via transfer switches to essential loads, such as motors, lighting, and control systems. It explicitly shows protective devices ensuring safety and redundancy. During design, engineers prioritized minimizing load imbalance and optimizing transformer sizing, guided by the schematic. Regular updates to the SLD helped maintenance teams promptly identify circuit issues and plan upgrades aligned with evolving operational needs.

Regulatory Compliance and Certification

Adherence to standards like IEEE 141 (The Electric Power Systems and Equipment) or IEC 60445 enhances quality assurance. These standards specify symbol sets, annotation practices, and documentation methods that ensure diagrams are universally comprehensible and legally defensible.

Limitations and Enhancements

While the single line diagram is invaluable, it does not convey wiring details or physical layouts. Its abstraction means that for detailed repair or installation work, more comprehensive wiring diagrams are necessary. Technological enhancements, such as integrating SLDs with digital twin environments or real-time SCADA data, extend functionality, offering dynamic insights into system status and performance.

Future Trends and Innovations

Emerging trends include the integration of Building Information Modeling (BIM) with electrical schematics, providing a holistic view combining structural and electrical data. Additionally, leveraging augmented reality (AR) in conjunction with SLDs allows field technicians to visualize electrical pathways overlayed onto physical spaces, revolutionizing maintenance workflows.

Conclusion: The Significance of mastering Single Line Diagrams

In essence, the single line diagram encapsulates the critical information required to understand, operate, and maintain electrical systems effectively. For those embarking on entry-level careers or seasoned professionals seeking to refine their skills, investing in a thorough grasp of SLDs yields dividends in safety, efficiency, and system reliability. As electrical systems grow increasingly complex, the ability to interpret and craft accurate SLDs remains an indispensable competence—one that bridges technical knowledge with practical, real-world application.

What are the main symbols used in a single line diagram?

+Common symbols include rectangles for transformers, circles with M for motors, zigzag lines for resistors, arcs for circuit breakers, and lines with annotations for busbars. Each symbol adheres to standardized conventions such as IEEE Std 315, ensuring cross-industry consistency.

How does a single line diagram differ from a wiring diagram?

+The primary distinction lies in detail and perspective. An SLD offers a simplified, abstracted view focusing on electrical relationships and system logic without physical wiring specifics. In contrast, wiring diagrams depict exact physical connections and installation details, essential for construction or repair.

Why is standardization important in creating SLDs?

+Standardization facilitates universal understanding, reduces misinterpretations in maintenance, and ensures compliance with safety regulations. It allows diverse teams—engineers, electricians, inspectors—to interpret diagrams reliably, thus maintaining system integrity and safety.

Can single line diagrams be automated in design?

+Yes. Modern electrical design software such as AutoCAD Electrical, ETAP, and SmartDraw can automate parts of the process, generating symbols, connections, and annotations based on input data. Automation enhances accuracy, saves time, and ensures compliance with standards.

How do I ensure my SLD complies with industry standards?

+Familiarize yourself with relevant standards like IEEE 315 or IEC 60417, utilize approved symbols, and follow industry best practices. Regularly review and validate your diagrams with industry peers or professional codes to maintain compliance and clarity.

Related Terms:

- Single line diagram symbols

- Electrical single line diagram pdf

- Free electrical single line diagram