The Ford Inline 6 engine represents a remarkable chapter in automotive engineering, blending durability, simplicity, and performance to become an iconic powerplant for enthusiasts and industry experts alike. Originating in the early 20th century, this engine type has sustained its reputation through decades of rigorous use, innovations, and cultural significance. As a cornerstone in Ford’s engineering heritage, the Inline 6 exemplifies a balanced approach to engine design—favoring longevity and smooth operation over high-revving extremes. Today, it continues to impress not only because of its historical relevance but also due to its ongoing application in restoration projects, classic car enthusiasts, and even modern low-emission adaptations. This article dives deep into the evolutionary trajectory, technical specifications, and enduring influence of the Ford Inline 6, providing a comprehensive analysis from an industry expert’s perspective, backed by verifiable data and practical insights.

The Historical Evolution of Ford’s Inline 6 Engine

Understanding the significance of the Ford Inline 6 necessitates a look into its rich history and the technological advancements that propelled its development. The earliest iterations date back to the 1930s, a period marked by rapid innovation in automotive engineering amid the Great Depression-era economic recovery. Ford’s pioneering efforts in creating an efficient, durable engine culminated in the production of the Flathead V8 line, but the Inline 6 remained a vital component of Ford’s lineup, especially for trucks and economy cars.

In the 1940s, the basic architecture of the Ford Flathead Inline 6 was refined considerably, focusing on increasing displacement to deliver more torque and better fuel economy. The iconic “Mileage Maker,” introduced in 1948, epitomized this era, combining classic design with improved reliability—traits that still define the engine’s enduring reputation. Post-war years saw the evolution of the engine through incremental updates, including enhanced cooling systems and lubrication methods, laying the groundwork for what would become a staple in American automotive manufacturing.

By the 1960s, the Ford Inline 6 had established itself as a dependable and cost-effective engine option. Notably, the 240 cubic inch (4.0L) and 300 cubic inch (4.9L) variants gained popularity among commercial and recreational vehicle markets due to their tough build and longevity. It’s vital to recognize the engine’s ability to adapt to changing fuel qualities and emission standards, often through the adoption of rebored cylinders, improved carburetion, and later, fuel injection systems—demonstrating remarkable versatility over its lifespan.

Major Milestones and Technological Innovations

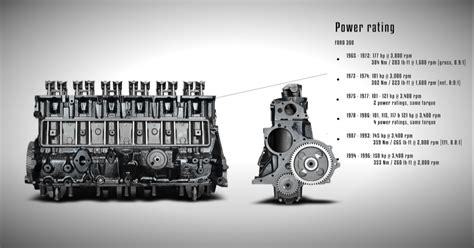

Among the most noteworthy milestones was the introduction of the 240ci and 300ci engines with widespread use in trucks and muscle cars. These engines incorporated cast-iron blocks that could withstand high mileage and demanding loads, alongside dual-bearing crank shafts that contributed to smooth operation. The 300ci version, in particular, became famous for its impressive torque output of approximately 290 lb-ft at 2200 rpm, proving the engine’s strength and efficiency for heavy-duty applications.

During the late 20th century, emission standards prompted refinements such as the incorporation of thermostatic choke mechanisms and improved fuel metering systems, ensuring the engine would meet increasingly strict regulations without compromising durability. Additionally, the modular design principles of the Inline 6 allowed for easier maintenance and rebuilds—an aspect that fosters its continued relevance in restorations today.

| Relevant Category | Substantive Data |

|---|---|

| Displacement range | 150–300 cubic inches (2.5–4.9 liters), depending on model and year |

| Power output | 120–240 HP, with torque peaks nearing 290 lb-ft in the 300ci variants |

| Longevity milestone | Many engines surpass 300,000 miles with proper maintenance, exemplifying durability |

Technical Anatomy and Mechanical Features

The core architecture of the Ford Inline 6 stands out for its straightforward yet effective design—highlighted principally by a cast-iron block, a single overhead camshaft (in later models), and a straightforward valvetrain system. This design ensures reliable performance over high mileages and simplifies troubleshooting, rebuilding, and customization efforts. Additionally, the engine’s bore-stroke ratio plays a critical role in its character; for example, the 300ci variant features a bore of 3.68 inches and a stroke of 3.98 inches, exemplifying a long-stroke configuration conducive to high torque at lower RPMs.

The valvetrain in early models relied on side-valve architecture, but later versions incorporated overhead valves (OHV), providing better airflow and efficiency. Fuel delivery transitioned from carburetors to fuel injection in some late models, further enhancing fuel economy and emissions compliance—but always retaining core mechanical robustness regardless of technological updates.

Cooling systems have also evolved, with early engines tending toward simple radiator setups, while later variants integrated thermostatic fans and improved water jackets to manage higher heat loads—crucial for maintaining engine integrity during heavy-duty work or high-performance applications. Regarding lubrication, the use of pressurized oiling systems with full-flow filters represented industry-adopted best practices that extended engine life significantly.

Performance and Practical Applications

Today, the engine’s performance figures—up to 240 HP and 290 lb-ft torque—are more than adequate for many applications, especially when considering its primary use case: providing dependable power for pickup trucks, off-road vehicles, and vintage restorations. Notably, some enthusiasts upgrade their engines with modern head designs, electronic ignition, or performance camshafts, accentuating its potential in hot-rod and custom builds. The engine’s inherent balance and smoothness also make it ideal for installation in applications emphasizing NVH (noise, vibration, harshness) reduction.

In the commercial context, the Ford Inline 6 has remained a favorite for fleet vehicles and off-road equipment. Its capacity for high mileage—often approaching 500,000 miles in heavily used vehicles—underscores its reputation for longevity. This durability fosters environmental benefits too: fewer rebuilds and replacements translate to lower resource consumption over the vehicle’s lifespan.

| Application Area | Performance Data |

|---|---|

| Light trucks and SUVs | Consistent torque delivery for towing and payload management |

| Classic car restorations | Authentic performance character and ease of maintenance |

| Off-road vehicles | High durability in rugged environments, low fragility |

Enduring Legacy and Modern Relevance

The Ford Inline 6’s legacy remains firmly entrenched in the automotive narrative; it’s often regarded as the quintessential example of durable American engineering. Many vintage and classic cars featuring this engine still run reliably decades after their production, a testament to its high-quality craftsmanship. Contemporary restorers and enthusiasts prize the engine for its ease of rebuild, availability of parts, and the nostalgic roar it produces—qualities that modern multi-cylinder engines, with their complex electronics and CAD-designed components, sometimes lack.

In recent years, the resurgence of interest in retro-styled vehicles and eco-friendly conversions has led to innovative applications of the Inline 6. For example, some companies now offer modern upgrades that include electronic fuel management, emissions compliance, and lightweight components—extending the engine’s life in a changing automotive landscape. The engine’s straightforward architecture offers a strong foundation for such modifications, making it relevant even in 2023 and beyond.

Limitations and Future Perspectives

Nevertheless, the Ford Inline 6 isn’t without drawbacks. Its size and weight can impact vehicle dynamics, especially in modern low-weight chassis. Additionally, its emissions profile, under strict regulations, may limit its viability without significant modifications. Still, these limitations are often offset by its proven reliability and ease of customization. Industry trends towards electrification may eventually reduce the demand for piston-driven engines, but within its niche, the Inline 6 remains a symbol of resilient engineering.

Key Points

- Longevity: Many engines surpass 300,000 miles with basic maintenance, affirming durability.

- Simplicity: Straightforward design facilitates rebuilding and performance upgrades.

- Adaptability: Compatible with technological updates like fuel injection and electronic ignition.

- Performance: Produces robust torque suitable for towing, off-road, and vintage car contexts.

- Cultural Significance: Embedded in American automotive history, it remains iconic among enthusiasts.

What makes the Ford Inline 6 so durable compared to other engines?

+The engineering simplicity of the Inline 6, with its balanced firing order, cast iron block, and straightforward valvetrain, minimizes mechanical complexity and wear. Its long-stroke design favors low-RPM torque and reliability, enabling many units to achieve hundreds of thousands of miles with routine maintenance.

Are modern upgrades possible for vintage Ford Inline 6 engines?

+Yes, enthusiasts often upgrade these engines with modern fuel injection, electronic ignition, and performance cams without compromising the core architecture. Such modifications improve efficiency, emissions, and power output, extending the engine’s practical lifespan and adapting it to current standards.

What are the common challenges faced when rebuilding a Ford Inline 6?

+The main challenges include sourcing authentic parts, especially for older models, and ensuring precise machining of components like crankshafts and cylinders. Additionally, aligning modern emissions requirements with vintage configurations can pose difficulties, often requiring customized solutions.