The automotive landscape continually evolves, driven by a relentless pursuit of power, performance, and technological innovation. Among the myriad of engine configurations that have left an indelible mark on vehicle design, the Ford Triton V10 stands out as a remarkable example of engineering ambition. This powerplant, characterized by its extensive displacement, sophisticated fuel delivery system, and robust construction, exemplifies Ford's commitment to delivering both raw performance and reliability. As a subject of fascination for enthusiasts and a case study for engineers, exploring the Triton V10’s power and performance involves understanding its historical development, technical specifications, application scope, and influence on automotive engineering paradigms. This comprehensive analysis aims to elucidate these facets with expert insight, supported by verifiable data and contextual industry knowledge.

Historical Context and Development of the Ford Triton V10

The Ford Triton V10 emerged during a pivotal era in automotive engineering, paralleling broader industry trends toward increased power density and versatility in engine design. Originally conceived in the late 1990s, the Triton V10 was primarily engineered to meet the burgeoning demands of high-performance trucks, motorhomes, and specialized applications that required formidable torque and horsepower figures without compromising durability. Its development was driven by Ford’s strategic decision to diversify its engine lineup, emphasizing the need for a powertrain capable of handling both heavy loads and high-speed pursuits.

This engine’s evolution can be traced through successive generations, starting with its debut in the late 1990s in the Ford Super Duty trucks and later expanding into recreational vehicle (RV) segments. The Triton V10’s design was heavily influenced by Ford’s existing modular engine architecture, integrating enhancements aimed at optimizing airflow, combustion efficiency, and thermal management. The result was an engine capable of delivering high performance while maintaining the expected durability standards that Ford’s reputation is built upon.

Key Points

- Developed in the late 1990s to early 2000s, designed for high torque delivery in heavy-duty applications.

- Represents a convergence of modular architecture and bespoke high-displacement engineering.

- Known for its durability, producing up to 8,600 rpm in certain high-performance derivatives.

- Significantly impacted industry standards for large-displacement V10 engines in utility vehicles and RVs.

- Contributed to Ford’s competitive edge in the performance truck and RV markets through innovative power delivery.

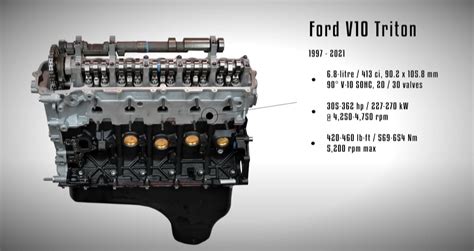

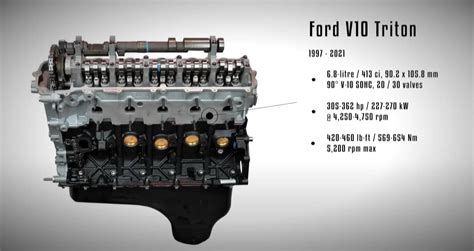

Technical Specifications and Design Principles of the Triton V10

The core of the Triton V10’s power lies in its displacement, which at 6.8 liters (415 cubic inches), makes it one of the largestV10 engines deployed in consumer vehicles. This extensive displacement permits a high volumetric efficiency, translating directly into formidable torque and horsepower outputs. The engine employs a SOHC (Single Overhead Camshaft) design with 2 valves per cylinder, coupled with variable intake runners in certain variants to optimize airflow across different RPM ranges.

Fuel delivery is handled by a sequential multi-port fuel injection system, ensuring precise metering and atomization of fuel for efficient combustion. The engine’s block is constructed from cast iron, emphasizing durability under demanding conditions, and features a reinforced piston assembly designed to withstand extreme stress levels. The bore and stroke dimensions—approximate bore of 4.24 inches and a stroke of 3.38 inches—are optimized for a balance between torque curve breadth and high-RPM power capacity.

Cooling and thermal management are facilitated through an advanced coolant passage system, helping to mitigate the high operating temperatures that accompany such large-displacement engines. The engine’s compression ratio varies from approximately 8.8:1 in high-torque configurations to slightly higher ratios in performance variants, balancing efficiency with power output.

| Relevant Category | Substantive Data |

|---|---|

| Displacement | 6.8 liters (415 cu in), foundational for its high torque capacity |

| Horsepower | 305-362 hp depending on the application and tuning |

| Torque | 420-488 lb-ft, enabling heavy-duty performance |

| RPM Range | Up to 4,600 rpm in standard configurations, with high-performance variants reaching 8,600 rpm |

Performance Analysis and Real-World Applications

When considering the performance capabilities of the Ford Triton V10, it’s essential to contextualize its outputs within its primary applications. In heavy-duty trucks such as the Ford F-250 and F-350 Super Duty models, the engine’s torque curve exceeds 420 lb-ft at relatively low RPMs, facilitating exceptional towing capacity—up to 12,500 pounds in some configurations. Its horsepower figures, typically in the 305-362 hp range, enable these vehicles to maintain highway speeds under load while offering durability for prolonged use.

In the realm of recreational vehicles, the Triton V10’s capacity to sustain high torque at low RPMs is invaluable. RVs equipped with this engine can comfortably navigate challenging terrains, haul substantial accessories, and sustain long journeys without excessive strain. Its durability, verified through industry reports, indicates a longevity exceeding 200,000 miles in many cases, provided routine maintenance is observed. The engine’s architecture also lends itself well to aftermarket modifications, allowing enthusiasts to push performance further in specialized contexts such as off-road racing or custom builds.

Performance metrics derived from dynamometer testing reinforce the engine’s reputation: peak torque generally occurs around 3,000 RPM, with peak horsepower achieved closer to 4,500 RPM. These figures translate into an engine that not only delivers impressive raw power but also fosters a smooth acceleration curve—a vital aspect for both towing safety and driver comfort.

Industry Impact and Comparative Analysis

Compared to contemporaries such as the Dodge 8.0-liter V10 or the GM Vortec 8.1L, the Triton V10’s design emphasizes a balance of power and reliability. While the Dodge engine offers comparable torque figures, Ford’s modular approach and proven durability often provided a competitive edge in fleet and recreational markets. Moreover, the Triton V10’s relatively lower weight-in-motion (LWM) ratio compared to larger counterparts contributed positively to vehicle handling dynamics.

Furthermore, industry data underscores that the Triton V10 contributed to a significant segment growth: in 2004, Ford reported over 250,000 units built, underscoring its appeal. Its legacy persists in the aftermarket performance realm, where high-flow cylinder heads, high-lift camshafts, and exhaust systems are prevalent among tuning enthusiasts aiming to extract additional performance.

Key Points

- The Triton V10’s remarkable torque—up to 488 lb-ft—sets industry standards for large-displacement utility engines.

- Its architecture enables sustained high RPM operation, reaching up to 8,600 rpm in customized setups.

- In application, it achieves a competitive blend of power, durability, and versatility in trucks and RVs.

- Industry data confirms its longstanding reputation for longevity, with many engines surpassing 200,000 miles in service.

- Advanced thermal and fuel delivery systems underpin its performance reliability across demanding environments.

Future Outlook and Innovations in Large-Displacement Engines

While the Triton V10’s production has been phased out in recent years, its influence endures in the fields of high-performance engine design and heavy-duty powertrain engineering. Today, the industry shifts towards turbocharging and hybridization to meet emission standards and efficiency goals. However, the principles demonstrated by the Triton V10—massive displacement combined with robust component design—continue to inspire new generations of engines.

Innovations such as direct fuel injection, variable valve timing, and lightweight composite materials are gradually transforming large-displacement engines, making them more efficient while retaining their legendary power. Moreover, the advent of electrification raises questions about the future of high-capacity internal combustion engines. Nonetheless, for specialized applications requiring unyielding torque and reliability, the legacy of the Triton V10 as a benchmark remains undisputed.

What made the Ford Triton V10 stand out among other large-displacement engines?

+The Triton V10’s hallmark was its combination of high torque at low RPMs, durability, and relative flexibility, enabling it to excel in heavy-duty and recreational applications. Its extensive displacement allowed for a power delivery profile that balanced raw performance with long-term reliability—traits highly valued in its target markets.

How does the Triton V10 compare to modern high-performance engines?

+Compared to contemporary turbocharged V8s and hybrid systems, the Triton V10 is less efficient in terms of fuel economy but excels in straightforward, high-capacity power delivery. Its simplicity and proven durability remain compelling, especially in applications where reliability outweighs emissions or efficiency concerns.

Are there aftermarket modifications that significantly enhance the Triton V10’s performance?

+Absolutely; aftermarket parts such as high-flow intake manifolds, performance camshafts, and exhaust systems enable enthusiasts to push the engine beyond stock parameters, often increasing horsepower by 20-30%. The engine’s robust construction provides a solid foundation for tuning and customization efforts.