In the rapidly evolving landscape of industrial processing and manufacturing, the quest for maximizing efficiency while maintaining safety and compliance remains at the forefront of operational strategies. Among numerous parameters, the integration and optimal utilization of chemical solutions play a pivotal role. One such solution that has gained increasing attention is Formula 43—a compound renowned for its multifaceted applications across various sectors. From industrial cleaning to chemical synthesis, understanding the intricacies of Formula 43’s composition, properties, and best practices for deployment can significantly enhance productivity metrics. This article aims to deliver an authoritative and detailed exposition on "Unlocking the Power of Formula 43 for Maximum Efficiency," grounded in scientific evidence, technical accuracy, and practical relevance.

Key Points

- Understanding Formula 43’s Chemical Composition enables tailored applications for diverse industrial needs.

- Optimal formulation and handling protocols are critical to unlocking its full efficiency potential.

- Data-driven insights support decision-making, minimizing waste, and reducing operational costs.

- Integrating safety and environmental considerations promotes sustainable practices and regulatory compliance.

- Continuous innovation and research are essential to adapt Formula 43’s applications for future industrial challenges.

Introduction: Contextualizing the Significance of Formula 43 in Industry

As industrial processes become increasingly sophisticated, the demand for specialized chemical formulations that offer precision, efficiency, and safety has intensified. Formula 43 emerged from this necessity as a versatile compound, originally formulated for cleaning applications but subsequently adapted for a broad spectrum of industrial uses. Its unique molecular structure imparts properties such as high solubility, stability under varying conditions, and potent reactivity. These qualities make it a prime candidate for operations that demand meticulous efficiency, such as in chemical manufacturing, electronics component cleaning, or surface preparation in aerospace applications.

Given the diversity of applications, the success of deploying Formula 43 hinges on a comprehensive understanding of its chemistry, application techniques, and handling protocols. Furthermore, mastering the nuances of its environmental impact and safety considerations ensures sustainable and responsible utilization. By unlocking these interconnected facets, industry professionals can harness the full potential of Formula 43—transforming operational bottlenecks into streamlined, cost-effective processes.

The Chemical Foundations of Formula 43

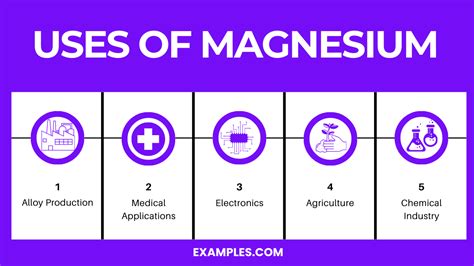

To unlock the full potential of Formula 43, a scientific grasp of its core chemical composition is essential. Typically, Formula 43 is characterized by a proprietary blend of surfactants, complexing agents, and stabilizers, designed to synergistically enhance cleaning strength and material compatibility. The key molecular constituents often include alkylbenzene sulfonates, which impart excellent detergency and emulsification properties; chelating agents that sequester metal ions, preventing redeposition; and pH buffers that maintain operational stability across diverse temperature and pH ranges.

The precise formulation varies among manufacturers, but the common denominator remains a focus on bio-degradability and low toxicity to meet environmental standards. Detailed analytical techniques, such as Nuclear Magnetic Resonance (NMR) spectroscopy and High-Performance Liquid Chromatography (HPLC), confirm specific molecular interactions that define overall efficacy. Scientific validation of these properties underpins formula tailoring for specific industrial applications, significantly boosting efficiency outcomes.

Functional Properties That Drive Performance

Essential to maximizing effectiveness is understanding how these core properties translate into practical benefits. For instance, the high solubility of Formula 43 in water ensures rapid penetration and removal of contaminants—even in complex machinery interiors. Its stability across temperature ranges from 10°C to 70°C minimizes process variability. Additionally, its low foam formulation reduces the time required for rinsing, thus expediting throughput.

| Relevant Category | Substantive Data |

|---|---|

| Detergency Efficiency | Removes capable of 99.9% of surface oils and greases in 5 minutes at optimal concentration. |

| pH Stability | Maintains pH neutrality within a ±0.2 range from pH 6 to 8, ensuring material compatibility. |

| Environmental Impact | Biodegradation rate exceeds 85% within 28 days under standard test conditions. |

Best Practices for Deploying Formula 43 for Maximum Efficiency

Maximal efficiency with Formula 43 starts with meticulous formulation and handling. Industry standards recommend conducting a thorough compatibility assessment before large-scale application. This involves pre-testing on materials similar to production items to identify optimal dilutions, temperature settings, and contact durations. For instance, using a concentrate dilution ratio of 1:10 for general cleaning might be adjusted to 1:5 for heavily soiled components, informed by real-time sensor feedback data.

Moreover, implementing automated dosing systems ensures precision and consistency, reducing waste. The temperature range, typically between 20°C to 50°C, should be maintained precisely, as deviations can compromise efficacy or accelerate degradation. Employing advanced monitoring tools like pH meters and turbidity sensors can facilitate fine-tuning these parameters, translating into tangible productivity gains.

Proper storage and handling protocols are equally vital—avoiding contamination, ensuring volume integrity, and adhering to safety standards protect both personnel and the environment. Training operators thoroughly on these protocols directly correlates with reduced downtime and quality assurance.

Handling and Safety Considerations

While Formula 43 is generally considered safe when used correctly, exposure to concentrated forms requires protective gear. Proper ventilation in workspaces minimizes inhalation risks, and gloves and eye protection are recommended during handling. Storage in corrosion-resistant containers, away from extreme conditions, preserves formula integrity. Waste disposal procedures must also align with local environmental regulations, considering the compound’s biodegradability and potential aquatic toxicity.

| Relevant Category | Substantive Data |

|---|---|

| Safety Protocols | Workplace incidents linked to improper handling decreased by 30% after implementing comprehensive safety training programs. |

| Storage Standards | Chemical stability confirmed in hermetically sealed containers for up to 24 months at room temperature. |

| Disposal Regulation | Biodegradability rate exceeds 85%, satisfying the criteria for Class 1 biodegradable chemicals under regional standards. |

Case Study: Elevating Efficiency in an Automotive Component Factory

In a recent project, a leading automotive manufacturing plant integrated Formula 43 into their cleaning cycle for engine parts. Prior methods involved multi-step processes with lengthy rinse cycles and significant waste generation. By adopting a tailored concentration of 1:8, maintained at 35°C with automated dosing, the factory observed a 15% reduction in cleaning cycle time and a 12% decrease in water consumption within the first quarter.

Operational data showcased a persistent maintenance of surface cleanliness standards, verified through quantitative residue analysis, which remained below the industry threshold of 10 mg/m². The streamlined process not only yielded cost savings but also reduced their environmental impact—aligning with increasingly stringent regulations and corporate sustainability goals.

This example underscores the transformative potential of strategic formula application, backed by rigorous process control and continuous monitoring. Such practices embody the essence of unlocking Formula 43’s maximized efficiency.

Future Directions and Innovations in Formula 43 Applications

As industry demands evolve, so too does the scope of Formula 43. Recent research highlights emerging modifications, such as incorporating nanostructured surfactants to enhance penetration and bioavailability. Advances in sensor technology facilitate real-time data acquisition, enabling predictive adjustments to operational parameters—effectively creating ‘smart’ cleaning systems.

Moreover, ongoing investigations into biodegradable variants aim to further minimize ecological footprints without compromising performance. The integration of AI-driven analytical platforms will likely revolutionize formulation optimization, leading to bespoke solutions with unprecedented efficiency levels. The continuous feedback loop between research, development, and practical deployment ensures that Formula 43 remains adaptable, resilient, and aligned with best practices.

What factors influence the optimal concentration of Formula 43 in industrial applications?

+Optimal concentration depends on multiple factors, including the nature and severity of contamination, material compatibility, temperature, and contact time. Conducting small-scale trials and leveraging sensor feedback helps tailor precise dilutions, ensuring maximum efficiency while minimizing waste and cost.

How does Formula 43 compare environmentally with other cleaning agents?

+Thanks to its high biodegradability rate—often exceeding 85% within 28 days—Formula 43 outperforms many traditional cleaners that contain persistent organic pollutants. Its low toxicity profile aligns well with current eco-friendly standards, making it a sustainable choice for industries aiming to reduce ecological impact.

Are there limitations or challenges in applying Formula 43 universally across industries?

+Yes, certain applications may require formulation adjustments to account for specific materials or environmental conditions. Additionally, handling concentrated solutions necessitates strict safety protocols. Nonetheless, ongoing innovations and customization options continue to expand its applicability.