The handling and storage of gas cylinders are critical aspects of safety in various industries, including healthcare, manufacturing, and construction. Gas cylinders, which contain compressed gases such as oxygen, nitrogen, and carbon dioxide, can be hazardous if not managed properly. According to the Occupational Safety and Health Administration (OSHA), gas cylinders are considered hazardous materials due to the potential risks associated with their storage, handling, and use. In this comprehensive guide, we will discuss the essential safety protocols and best practices for handling gas cylinders to minimize the risk of accidents and ensure a safe working environment.

Key Points

- Proper handling and storage of gas cylinders are crucial for safety

- Regular inspection and maintenance of gas cylinders and equipment are necessary

- Training and awareness programs for employees handling gas cylinders are essential

- Compliance with regulatory requirements and industry standards is mandatory

- Emergency preparedness and response planning are critical for gas cylinder safety

Understanding Gas Cylinder Hazards

Gas cylinders can pose several hazards, including explosion, fire, and toxic gas release. The primary hazards associated with gas cylinders are related to the physical and chemical properties of the gases they contain. For example, oxygen cylinders can ignite fires, while carbon dioxide cylinders can displace oxygen in the air, leading to asphyxiation. It is essential to understand the specific hazards associated with each type of gas cylinder to develop effective safety protocols.

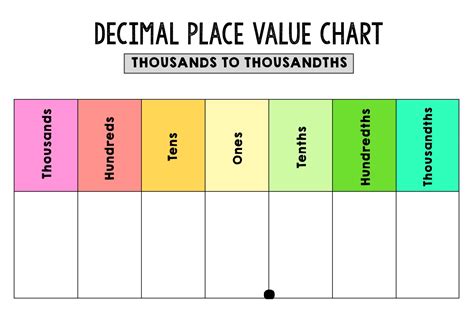

Gas Cylinder Classification and Labeling

Gas cylinders are classified and labeled based on the type of gas they contain and the associated hazards. The most common classification system is the Hazardous Materials Classification System, which categorizes gas cylinders into several classes, including flammable gases, oxidizing gases, and toxic gases. The labeling of gas cylinders is critical for identifying the hazards and taking necessary precautions. Labels should include information on the gas type, hazards, and safety precautions, as well as the manufacturer’s name and address.

| Gas Cylinder Classification | Hazards |

|---|---|

| Flammable Gases (e.g., Acetylene, Propane) | Fire and explosion hazards |

| Oxidizing Gases (e.g., Oxygen, Nitrous Oxide) | Fire and explosion hazards, as well as toxicity |

| Toxic Gases (e.g., Carbon Monoxide, Hydrogen Sulfide) | Toxicity and asphyxiation hazards |

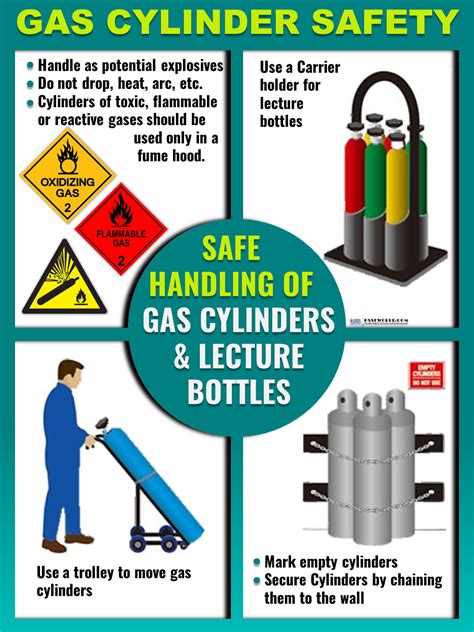

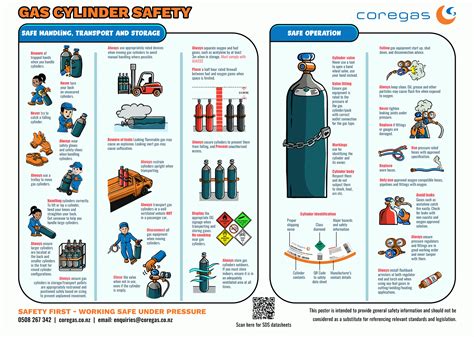

Safe Handling and Storage of Gas Cylinders

The safe handling and storage of gas cylinders are critical for preventing accidents and minimizing the risk of exposure to hazardous gases. Some essential safety protocols for handling gas cylinders include using proper lifting techniques, securing cylinders in an upright position, and keeping them away from heat sources and ignition sources. Additionally, gas cylinders should be stored in well-ventilated areas, away from incompatible materials and chemicals.

Gas Cylinder Storage and Transportation

Gas cylinders should be stored in designated areas, away from workstations and pedestrian traffic. The storage area should be well-ventilated, dry, and free from ignition sources. When transporting gas cylinders, it is essential to use proper handling equipment, such as carts or dollies, and to secure the cylinders to prevent movement or tipping. Gas cylinders should also be transported in an upright position, with the valve protection cap in place.

According to OSHA regulations, gas cylinders should be stored in accordance with the following guidelines:

- Store gas cylinders in a well-ventilated area, away from heat sources and ignition sources

- Keep gas cylinders away from incompatible materials and chemicals

- Store gas cylinders in an upright position, secured to prevent movement or tipping

- Use valve protection caps to prevent damage to the valve and regulator

What are the primary hazards associated with gas cylinders?

+The primary hazards associated with gas cylinders include explosion, fire, and toxic gas release. The specific hazards depend on the type of gas contained in the cylinder.

How should gas cylinders be stored and transported?

+Gas cylinders should be stored in well-ventilated areas, away from heat sources and ignition sources. When transporting gas cylinders, it is essential to use proper handling equipment and to secure the cylinders to prevent movement or tipping.

What are the essential safety protocols for handling gas cylinders?

+The essential safety protocols for handling gas cylinders include using proper lifting techniques, securing cylinders in an upright position, and keeping them away from heat sources and ignition sources. Regular inspection and maintenance of gas cylinders and equipment, as well as proper training and awareness programs for employees, are also crucial.

Regulatory Requirements and Industry Standards

The handling and storage of gas cylinders are subject to various regulatory requirements and industry standards. OSHA regulations, for example, provide guidelines for the safe handling and storage of gas cylinders, including requirements for labeling, storage, and transportation. Additionally, industry standards, such as those developed by the Compressed Gas Association (CGA), provide best practices and guidelines for the safe handling and storage of gas cylinders.

Compliance with Regulatory Requirements

Compliance with regulatory requirements is essential for ensuring gas cylinder safety. Employers must ensure that their employees are properly trained and equipped to handle gas cylinders safely, and that the workplace is free from hazards associated with gas cylinders. Regular inspections and maintenance of gas cylinders and equipment are also necessary to prevent accidents and ensure compliance with regulatory requirements.

In conclusion, the safe handling and storage of gas cylinders are critical for preventing accidents and minimizing the risk of exposure to hazardous gases. By understanding the hazards associated with gas cylinders, following proper safety protocols, and complying with regulatory requirements and industry standards, employers and employees can ensure a safe working environment and prevent accidents. Remember, gas cylinder safety is everyone’s responsibility, and it requires a proactive and vigilant approach to prevent accidents and ensure a safe and healthy work environment.