Effective inventory management is crucial for businesses across various industries, as it directly impacts profitability, customer satisfaction, and operational efficiency. The goal of inventory management is to maintain an optimal stock level, ensuring that there is enough stock to meet customer demand without overstocking, which can lead to waste and unnecessary storage costs. In this context, understanding and implementing sound inventory strategies is key to success. Let's delve into five critical inventory tips that can help businesses optimize their inventory management processes.

Key Points

- Implement a Just-In-Time (JIT) Inventory System to minimize storage needs and reduce waste.

- Use Inventory Management Software to automate tracking and forecasting.

- Conduct Regular Inventory Audits to ensure accuracy and identify discrepancies.

- Apply the 80/20 Rule to focus on high-demand items.

- Develop a Return and Refund Policy to handle unwanted or defective stock efficiently.

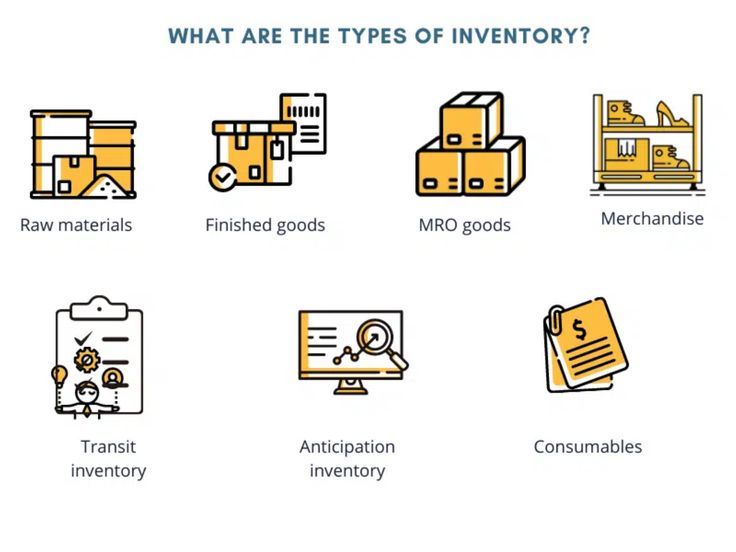

Understanding Inventory Management Basics

Inventory management encompasses the planning, organizing, and supervising of inventory from raw materials to finished goods. It involves balancing inventory levels to meet customer demand while minimizing costs. Effective inventory management can lead to reduced stockouts, lower inventory holding costs, and improved customer service. Businesses should strive to achieve an optimal balance between too little stock, which can result in lost sales, and too much stock, which can lead to unnecessary expenses.

Tip 1: Implement a Just-In-Time (JIT) Inventory System

A JIT system is designed to receive inventory just in time to meet customer demand, thereby minimizing the need for storage space and reducing waste. This approach requires precise forecasting and close relationships with reliable suppliers. Implementing JIT can significantly reduce inventory holding costs and improve cash flow. However, it also increases the risk of stockouts if demand suddenly increases or if there are supply chain disruptions.

| Inventory Metric | Description |

|---|---|

| Inventory Turnover | Measures how often inventory is sold and replaced within a given period. |

| Days Inventory Outstanding (DIO) | Average number of days inventory remains in stock before it's sold. |

| Fill Rate | Percentage of customer orders that are filled from existing inventory. |

Utilizing Technology for Inventory Management

Inventory management software has revolutionized the way businesses track, manage, and analyze their inventory. These systems offer real-time visibility into inventory levels, automate reordering processes, and provide forecasting tools based on historical data and seasonal trends. By leveraging such technology, companies can make more informed decisions about their inventory, reduce errors, and enhance overall efficiency.

Tip 2: Use Inventory Management Software

Selecting the right inventory management software is critical. The chosen system should align with the business’s specific needs, including its size, industry, and operational complexity. Key features to consider include barcode scanning, cloud accessibility, and integration with existing accounting and e-commerce platforms. The software should also offer analytics and reporting capabilities to help in making strategic inventory decisions.

For businesses operating in multiple locations or with complex supply chains, inventory management software can provide a centralized view of inventory across all warehouses and distribution centers, facilitating better stock allocation and minimizing the risk of overstocking or understocking.

Importance of Auditing and Analysis

Regular inventory audits are essential for ensuring the accuracy of inventory records and identifying any discrepancies. Audits involve physically counting inventory and comparing the results with the quantities recorded in the inventory management system. This process helps in detecting errors, theft, or damage and provides an opportunity to adjust inventory levels accordingly.

Tip 3: Conduct Regular Inventory Audits

Audits should be conducted periodically, with the frequency depending on the business’s size, inventory turnover, and past experiences with inventory discrepancies. Implementing cycle counting, where a small portion of the inventory is counted on a regular basis, can help in maintaining the accuracy of inventory records without the need for a full physical count.

How often should inventory audits be performed?

+The frequency of inventory audits depends on several factors, including the size of the business, the nature of the inventory, and past experiences with inventory discrepancies. For many businesses, conducting audits on a quarterly basis is sufficient, but this may vary based on specific needs.

What are the benefits of implementing a JIT inventory system?

+Implementing a JIT system can significantly reduce inventory holding costs, minimize waste, and improve cash flow. It also allows businesses to be more responsive to changes in demand, provided they have reliable suppliers and accurate demand forecasting.

Strategic Inventory Management Practices

Beyond the technical aspects of inventory management, adopting strategic practices can further enhance inventory efficiency. This includes applying the 80⁄20 rule, also known as the Pareto principle, which suggests that 80% of sales come from 20% of the inventory items. Focusing on these high-demand items can help in optimizing inventory levels and reducing unnecessary stock.

Tip 4: Apply the 80⁄20 Rule

By identifying the most profitable and in-demand products, businesses can prioritize their inventory management efforts. This involves ensuring that these critical items are always in stock and that their inventory levels are closely monitored. Additionally, businesses can consider implementing different service levels for different products based on their demand and profitability.

Handling Returns and Refunds

An often-overlooked aspect of inventory management is how to handle returns and refunds efficiently. Developing a clear return and refund policy not only improves customer satisfaction but also helps in managing unwanted or defective stock. This policy should outline the conditions under which returns are accepted, the process for initiating a return, and how refunds or exchanges are handled.

Tip 5: Develop a Return and Refund Policy

A well-designed return policy can reduce the administrative burden associated with handling returns and minimize the impact on inventory levels. It’s essential to communicate this policy clearly to customers to manage expectations and reduce disputes. The policy should also be flexible enough to accommodate different scenarios, such as defective products or customer change of mind, while protecting the business’s interests.

In conclusion, effective inventory management is about striking a balance between meeting customer demand and minimizing costs. By implementing a JIT system, utilizing inventory management software, conducting regular audits, applying the 80⁄20 rule, and developing a return and refund policy, businesses can significantly improve their inventory efficiency and contribute to their overall profitability and competitiveness. Each of these strategies requires careful consideration of the business’s specific circumstances and market conditions, as well as ongoing monitoring and adjustment to ensure they remain effective.