Ensuring a reliable and safe electrical grounding system is fundamental for both residential and industrial electrical installations. Among the essential tools designed to facilitate this process, the ground rod driver stands out as a key component in achieving optimal grounding efficacy. This comprehensive guide explores the intricacies of ground rod drivers, detailing their design, application, and the best practices for their use. With a focus on practical implementation supported by technical insights, the discussion aims to equip electricians, electrical engineers, and DIY enthusiasts with authoritative knowledge rooted in industry standards and empirical data. The importance of proper grounding cannot be overstated, not only for system performance but also for safety considerations—making understanding and utilizing ground rod drivers a critical aspect of electrical work.

Understanding Grounding and the Role of Ground Rod Drivers

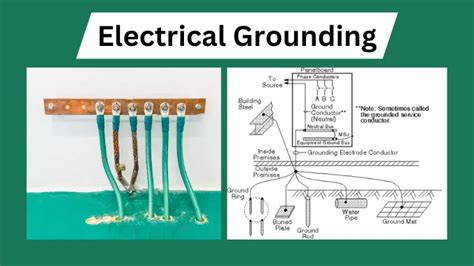

At its core, electrical grounding provides a safe path for fault currents to dissipate into the earth, protecting both personnel and equipment. A typical grounding system involves establishing a conductive connection between the electrical system and a grounding electrode, often a copper or steel rod driven into the ground. The effectiveness of this connection heavily depends on the quality of installation—specifically, ensuring sufficient contact and low resistance between the rod and soil. This is where the ground rod driver becomes indispensable.

The ground rod driver is a specialized tool designed to facilitate the forceful and precise insertion of grounding rods into the earth. Unlike traditional sledgehammers or manual driving methods, these devices offer controlled force, minimizing damage to the rod and optimizing contact integrity. Their design varies from simple mechanical rams to hydraulic systems capable of delivering high-impact forces that significantly reduce installation time and physical effort. Proper application of a ground rod driver ensures consistent depth, alignment, and contact quality, which are critical to meet industry standards such as the NEC (National Electrical Code) and IEEE guidelines.

Technical Foundations of Ground Rod Driving Mechanics

The core principle behind a ground rod driver is the application of kinetic energy to drive the rod into the ground without causing deformation or weakening of the material. Hydraulic ground rod drivers operate through pressurized fluid systems, often powered by small electric or gasoline engines, delivering repetitive powerful blows with minimal operator fatigue. Mechanical ram devices, on the other hand, utilize a spring-loaded or weight-driven system to produce forceful impacts. The choice between these systems depends on project scale, ground conditions, and operator preference.

High-quality drivers are equipped with features like adjustable stroke length, ergonomic handles, and safety shields to prevent accidents. They must also be compatible with various rod diameters—commonly ranging from 3⁄8-inch to 1⁄2-inch (9.5 to 12.7 mm)—appearing frequently in commercial electrical grounding tasks. The precise control of impact force ensures that the grounding rod penetrates the soil to the depth prescribed by the electrical standards—often at least 8 feet (2.44 meters) to reach moist soil layers conducive to low-resistance grounding.

From a scientific point of view, the effectiveness of a ground rod installation is often measured as the resistance to ground (Rg). Industry standards recommend a resistance below 25 ohms for most grounding systems, with some cases accepting up to 5 ohms for critical applications. Proper driven depth, facilitated by an efficient ground rod driver, directly correlates with reaching these targets by increasing contact surface area and soil conductivity. Empirical studies suggest that well-driven rods reduce Rg significantly—often by 50% compared to manually hammered rods under similar conditions.

Types of Ground Rod Drivers and Their Features

Hydraulic Ground Rod Drivers

Hydraulic versions are regarded as the Gold Standard for large-scale or frequent grounding operations. Their power source—electric motors or gas engines—drives a piston that delivers high-force impacts rapidly and repeatedly. These models typically feature adjustable pressure settings, allowing operators to calibrate impact force according to soil hardness and rod size. Hydraulic drivers are preferred in environments where consistency and speed are paramount, such as construction sites or utility installations.

| Relevant Category | Substantive Data |

|---|---|

| Impact Force | Up to 10,000 pounds (4,535 kg) per impact |

| Power Source | Electric or gasoline |

| Adjustment Capabilities | Yes, via pressure controls |

| Operational Efficiency | drives rods 3-4 times faster than manual methods |

Mechanical Ram Drivers

Mechanical ram systems rely on stored potential energy, such as compressed springs or counterweights, to deliver impacts. They’re often portable, lightweight, and more economical—ideal for minor installations or situations where power sources are unavailable. While they require more manual effort, advances in design have improved impact consistency and reduced operator fatigue. These tools are suitable for residential grounding jobs or small commercial projects where speed is less critical.

Advantages & Limitations

The primary advantage of hydraulic systems is their ability to generate high-impact forces with minimal physical effort, leading to faster, more uniform installations. Conversely, spring-based drivers are more affordable and portable but demand more physical effort and may produce less consistent penetration depths, especially in dense or rocky soils. Selecting the appropriate driver depends on project scope, soil conditions, and available resources.

Key Points

- High-impact impact with hydraulic drivers significantly reduces installation time and improves contact quality.

- Proper driver selection based on soil type enhances grounding system reliability.

- Consistency in depth and alignment is vital for compliance with electrical standards and system safety.

- Advanced adjustable features enable customization for specific project demands.

- Operator safety and ergonomic design should be prioritized to prevent injuries during use.

Best Practices for Ground Rod Driving and Connecting

Implementing an effective grounding system goes beyond simply choosing the right driver. Proper techniques and adherence to established standards ensure the long-term safety and effectiveness of the system. First, it’s prudent to assess soil conditions—rocky, sandy, or clay soils can influence driving strategy and impact force requirements.

Before driving, inspect the rod and driver for any damage or corrosion. Proper alignment—keeping the rod vertical—reduces the risk of bending or breaking, which can compromise the entire grounding system. During operation, applying steady, controlled impacts ensures optimal depth without damaging the rod or soil structure. Using a ground rod driver with adjustable impact settings allows adaptation to varying soil conditions.

The goal is to reach the desired depth, typically at least 8 feet, ensuring the grounding system meets or exceeds local code requirements. Once driven, the connection point at the rod’s top should be cleaned to remove corrosion or debris, and a robust clamp—preferably copper or aluminum—should be used. These actions create a low-resistance pathway, vital for system efficiency during fault events or lightning strikes.

Regular inspection and testing of the grounding system—using fall-of-potential or clamp-on testers—are recommended to verify compliance and operational integrity over time. Such preventative measures safeguard the entire electrical system, emphasizing the importance of meticulous installation practices empowered by the appropriate driving tools.

Addressing Common Challenges in Grounding

One universal challenge is poor soil conductivity, which can hinder achieving the desired resistance levels. In such cases, supplementing the grounding system with chemical or conductive backfill can be effective. Additionally, initial resistance measurements can be misleading if rods are not driven to sufficient depth or if corrosion develops over time.

Another issue is equipment damage—improper use of a ground rod driver or misalignment can deform the rod, creating eventual failure points. Recognizing signs of wear and adhering to manufacturer instructions extend tool lifespan and ensure safety during operation. Operators must also remain cautious of underground utilities to avoid accidents or costly damages.

Future Trends in Grounding Technology and Ground Rod Drivers

The evolution of electrical grounding tools reflects a trend toward automation, precision, and user safety. Autonomous or semi-autonomous hydraulic drivers equipped with sensors to measure soil resistance and adjust impact force in real-time are emerging. These innovations aim to link the driver directly with digital monitoring systems, providing instant feedback on installation quality.

Moreover, advancements in materials science are producing more durable, corrosion-resistant rods and clamps, ensuring longer system longevity. Hybrid driver designs combining hydraulic and mechanical principles may offer increased portability without sacrificing power. Integration of ergonomic features and safety systems reduces operator fatigue and prevents injuries, aligning with industry safety standards.

As electrical systems grow more complex—particularly with the rise of renewable energy sources and smart grid technologies—the importance of reliable grounding intensifies. Ground rod drivers will likely become an integral part of automated installation systems, ensuring compliance with demanding specifications while maintaining efficiency and safety.

What are the key differences between hydraulic and mechanical ground rod drivers?

+Hydraulic drivers utilize pressurized fluid systems to deliver high-impact, consistent blows, significantly reducing installation time and operator effort. Mechanical ram drivers rely on spring-loaded or weight-driven impacts, are more portable and cost-effective but require more manual effort and may produce less uniform results. The choice hinges on project scale, soil conditions, and available resources.

How deep should a grounding rod be driven according to industry standards?

+Typically, grounding rods should be driven at least 8 feet (2.44 meters) into the ground to reach moist soil layers with low resistance. However, specific requirements can vary based on local codes and soil conditions, with some applications necessitating deeper penetrations or supplemental grounding methods to achieve resistance below 25 ohms.

What are best practices for testing the effectiveness of a grounding system post-installation?

+Testing usually involves the fall-of-potential method, where probes are placed at set distances to measure the voltage gradient and calculate resistance. Alternatively, clamp-on testers can provide quick, non-intrusive measurements. Regular testing ensures the system maintains low resistance levels, necessary for safety and compliance, and should be repeated periodically or after soil condition changes.

Can the use of advanced technology like automated impact adjustment improve grounding efficiency?

+Yes, automated impact adjustment systems equipped with soil resistance sensors allow for real-time calibration of impact force, optimizing the driving process for varying soil conditions. This technology enhances consistency, reduces installation time, and ensures the grounding system meets the required resistance thresholds more reliably.