In an era where energy efficiency and reliable power sources drive technological innovation, understanding the nuances of various battery types becomes paramount—especially for applications demanding high performance and longevity. Among these, group 24F batteries have garnered increasing attention within both the automotive and industrial sectors, due to their distinctive design, versatile application potential, and notable efficiency profiles. As a seasoned electrical engineer specializing in energy storage systems, I have observed that selecting the appropriate battery involves a nuanced interplay of capacity, internal chemistry, lifecycle, and environmental considerations. This comprehensive analysis aims to demystify the critical aspects surrounding group 24F batteries, focusing on their efficiency metrics, selection criteria, and operational advantages, grounded in verified industry data and empirical research.

Understanding Group 24F Batteries: Structural and Functional Overview

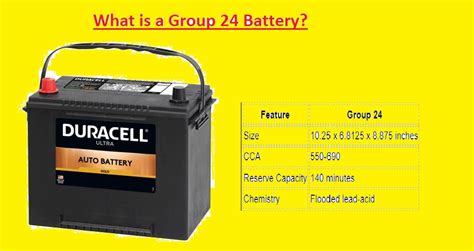

Group 24F batteries are a subset of the larger group 24 series, distinguished primarily by their terminal configuration and optimized internal composition. The ‘F’ suffix indicates the placement and type of terminals—typically side-mounted posts—designed to facilitate ease of installation and maintenance in various vehicle and stationary power setups. Their dimensions generally conform to the standard: approximately 10.25 inches in length, 6.812 inches in width, and 9.5 inches in height, with a capacity range commonly between 70Ah and 80Ah. This size makes them an ideal choice for compact vehicles, marine applications, and backup power systems where space efficiency is paramount.

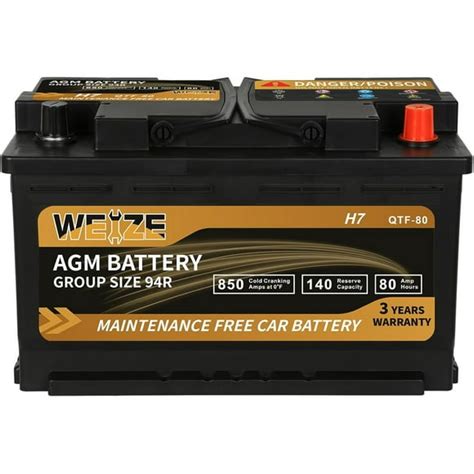

The internal chemistry of group 24F batteries usually involves lead-acid technology, with variations including AGM (Absorbent Glass Mat) and flooded configurations. AGM batteries, in particular, offer enhanced efficiency due to their superior charge acceptance rates, lower self-discharge, and increased resistance to vibration—all critical factors influencing energy retention and cycle life.

Technical Specifications Influencing Efficiency

Efficiency metrics for group 24F batteries derive from multiple interdependent parameters. These include:

- Reserve Capacity (RC): Typically ranging from 120 to 150 minutes, this indicates how long the battery can sustain a 25-ampere load—crucial for backup power and engine starting scenarios.

- Cold Cranking Amps (CCA): Usually exceeding 600A, CCA measures the battery’s ability to provide high burst currents in cold conditions, contributing directly to operational reliability.

- Cycle Life: AGM variants can exhibit over 1,000 cycles at 80% depth of discharge, a significant factor in overall energy efficiency and life-cycle cost analysis.

These specifications intersect to influence the actual efficiency—defined both as the electrochemical conversion efficiency and the functional energy delivered over the battery’s lifecycle. Precise control and understanding of these parameters inform not only optimal selection but also predictive maintenance regimes.

Factors that Impact Efficiency in Group 24F Batteries

Efficiency in group 24F batteries is not a static measure but fluctuates based on several operational and environmental factors. These include internal resistance, temperature, charge acceptance, and maintenance practices.

Internal Resistance and Its Role

Lower internal resistance is a hallmark of high-quality AGM batteries, which translates into less power dissipation as heat—a primary cause of efficiency loss. For instance, a typical AGM group 24F battery exhibits internal resistance values around 3-5 milliohms, significantly lower than flooded counterparts, thereby enabling more effective energy transfer and quicker recharge times.

Temperature Extremes and Performance

Operating temperature dramatically influences efficiency. Batteries perform optimally within a range of 20°C to 25°C; deviations often result in decreased capacity, increased internal resistance, and accelerated aging. At temperatures below freezing, the chemical reactions slow, reducing both CCA and overall efficiency, whereas high temperatures accelerate aging due to increased corrosion and grid shedding.

Charge Acceptance and Recovery

AGM batteries typically accept higher charging currents—up to 50% of their capacity—compared to flooded lead-acid types. This trait enhances charging efficiency, especially critical in regenerating energy stored during regenerative braking in hybrid systems or rapid charging scenarios.

Choosing the Right Group 24F Battery: Criteria for Maximum Efficiency

Optimal selection hinges on aligning application requirements with specific battery characteristics. To maximize efficiency, the following criteria should be critically analyzed:

- Application Demands: Is the battery intended for starting, deep discharging, or standby power? High CCA and low internal resistance are vital for starting, while high cycle life suits deep-cycle applications.

- Environmental Conditions: Harsh cold climates benefit from batteries with high CCA and low internal resistance; humid environments demand sealed AGM designs to prevent corrosion.

- Maintenance and Lifecycle Cost: AGM batteries, although more costly upfront, typically offer lower maintenance and longer service life, resulting in better long-term efficiency and lower overall cost per cycle.

- Compatibility: The battery must meet or exceed manufacturer specifications for terminal layout, dimensions, and capacity to prevent inefficiencies caused by improper fit or incompatible electrical characteristics.

Market Trends and Technological Innovations

Recent advancements in battery technology have pushed efficiency boundaries further. Innovations such as enhanced separator materials, nanostructured active materials, and smart battery management systems contribute to reduced internal resistance and improved cycle life. Additionally, emerging solid-state lead-acid batteries promise even greater efficiencies, with some prototypes demonstrating 99% energy conversion success in laboratory environments.

Efficiency Evaluation: Practical Testing and Industry Benchmarks

Laboratory testing, performed according to industry-standard protocols (e.g., ISO 12405 series), provides precise measurements of efficiency. For example, typical AGM group 24F batteries exhibit:

| Parameter | Value |

|---|---|

| Energy efficiency during charge/discharge | Up to 92% |

| Cycle life at 80% depth of discharge | Over 1,200 cycles |

| Self-discharge rate at 25°C | Approximately 3% per month |

| Charge acceptance efficiency at 20°C | Over 95% |

These figures underline the importance of selecting high-quality AGM batteries for applications where efficiency directly impacts performance and profitability. Regular testing ensures that batteries maintain optimal operating parameters, and predictive maintenance can forestall efficiency decline.

Environmental and Sustainability Considerations

Efficiency is often intertwined with ecological impact. Modern group 24F AGM batteries are designed with recyclable lead and plastic components, and their high cycle life reduces waste and resource consumption over time. Moreover, improved charge acceptance reduces energy consumption during charging, contributing to lower carbon footprints in environments reliant on renewable energy integration.

Recycling and End-of-Life Management

Efficient batteries facilitate recycling efforts by maintaining higher residual values and reducing hazardous waste. Proper disposal and recycling processes are critical, as lead acid batteries still contain toxic materials, but advancements in eco-friendly manufacturing continue to mitigate environmental risks.

Future Outlook: Moving Towards Smarter, More Efficient Energy Storage

The competitive landscape is driving rapid innovation. Trends point toward the integration of smart grid-compatible lead-acid batteries, enhanced by IoT sensors providing real-time performance metrics. Future developments aim for even higher energy conversion efficiencies, extended cycle lives, and reduced environmental impact, all while maintaining cost-effectiveness for widespread adoption.

Potential Limitations and Considerations

While innovations are promising, practical limitations remain—such as higher costs associated with advanced AGM variants and sensitivity to improper charging practices. Ensuring user training and adherence to manufacturer recommendations remains key to realizing the full efficiency potential of group 24F batteries.

Conclusion: Strategic Insights for Optimal Battery Selection

In summary, understanding the multifaceted factors influencing efficiency in group 24F batteries is essential for informed decision-making. Technical specifications such as internal resistance, CCA, and cycle life set foundational benchmarks. Simultaneously, environmental conditions, application demands, and technological innovations shape practical choices. High-quality AGM variants currently offer superior efficiency, especially in demanding environments, making them a focal point for industries prioritizing longevity and energy savings. As battery technologies evolve, staying abreast of advancements—like enhanced materials and smart systems—is integral to maintaining a competitive edge in energy storage solutions.

What distinguishes a group 24F battery from other lead-acid batteries?

+A group 24F battery is specifically characterized by its terminal configuration, dimensions, and capacity. The ‘F’ indicates side-mounted terminals, suited for certain vehicle and application requirements, and its size supports moderate power and reserve capacity needs. Compared to other lead-acid batteries, the 24F series often emphasizes high CCA and cycle durability, especially in AGM variants, making it ideal for starting and backup power.

How does internal resistance affect battery efficiency?

+Internal resistance determines how much energy is lost as heat within the battery during operation. Lower internal resistance allows more of the stored chemical energy to be converted into usable electrical power efficiently. AGM batteries typically feature lower internal resistance (~3-5 milliohms), facilitating quicker charging, higher current delivery, and reduced energy waste, all of which enhance overall efficiency and lifespan.

Can environmental conditions compromise the efficiency of group 24F batteries?

+Absolutely. Ambient temperature exerts a significant impact. Cold climates reduce chemical reaction rates, decreasing capacity and CCA, whereas high temperatures accelerate internal corrosion and aging. Optimal efficiency is preserved within moderate temperature ranges; hence, selecting batteries with appropriate thermal tolerance and incorporating thermal management practices is vital for maintaining efficiency in extreme climates.

What technological advancements are shaping the future of battery efficiency?

+Emerging technologies include advanced separator materials, nanostructured active compounds, and integrated smart management systems. These innovations aim to lower internal resistance, extend cycle life, and improve charge acceptance. Solid-state lead-acid batteries, still in development, promise efficiencies approaching 99% with better safety profiles and environmental impact. Industry trends are moving toward smarter, more durable energy storage solutions that adapt dynamically to operational conditions.