When it comes to mechanical building, whether you're a seasoned engineer or an enthusiastic hobbyist, understanding the fundamental principles and best practices is crucial for creating efficient, reliable, and innovative mechanical systems. Mechanical building encompasses a wide range of activities, from designing and constructing machinery to assembling and maintaining mechanical components. In this article, we'll delve into five essential tips that can guide you through the process of mechanical building, ensuring your projects are not only successful but also reflect a high level of professionalism and expertise.

Key Points

- Start with a clear and detailed design to ensure your project's success

- Choose the right materials based on the project's requirements and environmental conditions

- Implement safety measures to protect yourself and others from potential hazards

- Follow a systematic approach to assembly to avoid mistakes and ensure efficiency

- Test and iterate your design to identify and fix any issues before finalizing the project

Tip 1: Detailed Design and Planning

A thorough and well-considered design is the cornerstone of any successful mechanical building project. Before you begin assembling your project, it’s essential to have a clear and detailed design. This involves not just sketching out what you want to build but also considering the materials you’ll need, the tools required, and any potential challenges you might face. Utilizing computer-aided design (CAD) software can be incredibly helpful in this stage, as it allows you to create precise models of your project and simulate its performance under various conditions. Remember, a good design should balance functionality, aesthetics, and cost-effectiveness.

The Importance of Material Selection

Material selection is another critical aspect of mechanical building. Different materials have different properties—such as strength, durability, and resistance to corrosion—that make them more or less suitable for specific applications. For instance, if your project will be exposed to water or high temperatures, you’ll need to choose materials that can withstand these conditions. Always research and test your materials before committing to them for your project.

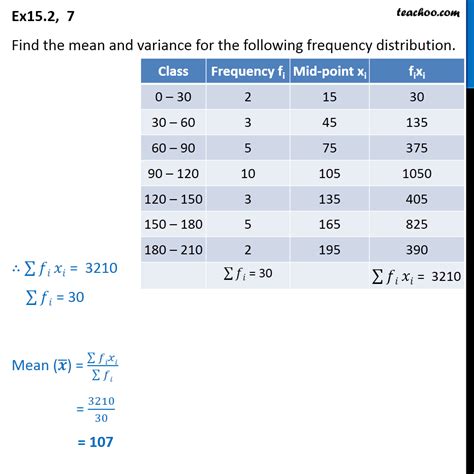

| Material | Properties | Common Uses |

|---|---|---|

| Aluminum | Lightweight, corrosion-resistant | Aircraft, automotive parts |

| Stainless Steel | High strength, resistant to corrosion | Cookware, medical equipment |

| Copper | Excellent conductor, resistant to corrosion | Electrical wiring, plumbing |

Tip 2: Safety First

Safety should always be your top priority when engaging in mechanical building. This means taking precautions to protect yourself from potential hazards such as sharp edges, heavy objects, and electrical components. Wearing appropriate personal protective equipment (PPE) like gloves, safety glasses, and a face mask can significantly reduce the risk of injury. Additionally, ensure that your workspace is well-ventilated and free from clutter to prevent accidents and facilitate easy movement.

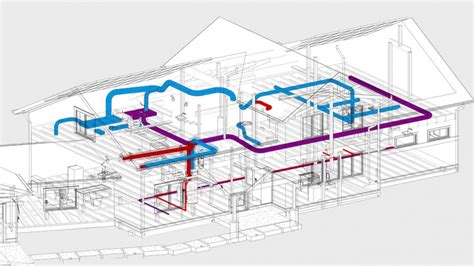

Systematic Assembly

A systematic approach to assembly is key to ensuring that your project comes together efficiently and correctly. Start by organizing your components and tools, and then proceed step by step according to your design plan. This not only helps in avoiding mistakes but also makes the process less overwhelming. Consider documenting your assembly process, as this can be invaluable if you need to disassemble or repair your project in the future.

Tip 3: Assembly and Testing

After you’ve assembled your project, it’s crucial to test it under various conditions to ensure it performs as expected. This stage can reveal flaws in your design or assembly process that you might not have anticipated. Be prepared to iterate on your design based on the results of your testing. Iteration is a natural part of the engineering process, and it’s better to identify and fix issues early on rather than after the project is complete.

Iterative Design

An iterative approach to design involves cycling back through the design process based on feedback from testing and performance analysis. This might involve refining your design, changing materials, or adjusting parameters to optimize performance. Embracing an iterative mindset allows you to refine your project continuously, leading to a better final product.

What is the most critical step in mechanical building?

+While all steps are crucial, having a detailed and well-considered design is foundational. It sets the stage for the success of your project by anticipating challenges, specifying the right materials, and guiding the assembly process.

How do I ensure safety during mechanical building projects?

+Always wear appropriate PPE, ensure your workspace is safe and well-ventilated, and follow safety guidelines for tools and equipment. Additionally, be mindful of potential hazards specific to your project, such as electrical or chemical risks.

What if my project doesn't work as expected after assembly?

+This is a common scenario. The key is to approach the issue systematically. Review your design and assembly process, consult your documentation, and test individual components to identify where the issue lies. Be prepared to make adjustments and iterate on your design as needed.

In conclusion, mechanical building is a complex and rewarding field that requires careful planning, attention to detail, and a commitment to safety and quality. By following these tips and maintaining a mindset open to iteration and improvement, you can ensure that your projects are not only successful but also reflect the highest standards of engineering practice. Whether you’re working on a personal project or a professional assignment, the principles outlined here will serve as a solid foundation for achieving your goals in mechanical building.