Mechanical systems are the backbone of many industries, from manufacturing and construction to automotive and aerospace. These systems, which include engines, pumps, gears, and other components, play a crucial role in ensuring the smooth operation of machinery and equipment. However, they can be complex and require regular maintenance to prevent breakdowns and ensure optimal performance. In this article, we will explore five mechanical system tips that can help you improve the efficiency, reliability, and lifespan of your mechanical systems.

Key Points

- Regular lubrication is essential for reducing friction and wear on moving parts

- Proper alignment of components can help prevent vibrations and reduce stress on the system

- Regular inspection and maintenance can help identify potential issues before they become major problems

- Upgrading to high-efficiency components can help reduce energy consumption and improve overall system performance

- Implementing a preventive maintenance schedule can help minimize downtime and reduce repair costs

Understanding Mechanical Systems

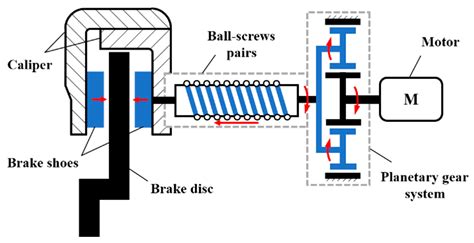

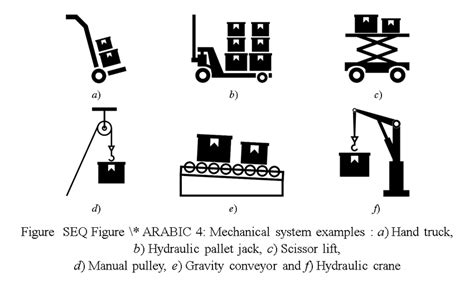

Mechanical systems are designed to perform specific tasks, such as transmitting power, controlling motion, or regulating temperature. They typically consist of a combination of components, including motors, pumps, gears, bearings, and other mechanical elements. To ensure optimal performance, it is essential to understand how these components interact and affect the overall system. For example, a well-designed gear system can help reduce wear and tear on other components, while a properly sized motor can help prevent overheating and improve overall efficiency.

Tip 1: Regular Lubrication

Lubrication is critical for reducing friction and wear on moving parts. Without proper lubrication, components can overheat, corrode, or wear down prematurely, leading to costly repairs and downtime. Regular lubrication can help extend the lifespan of your mechanical system and improve its overall performance. For example, a study by the National Institute of Standards and Technology found that regular lubrication can reduce energy consumption by up to 20% and extend the lifespan of mechanical components by up to 50%.

| Component | Lubrication Frequency |

|---|---|

| Engine | Every 5,000 miles |

| Gearbox | Every 10,000 miles |

| Bearings | Every 20,000 miles |

Implementing Preventive Maintenance

Preventive maintenance is essential for identifying potential issues before they become major problems. Regular inspection and maintenance can help you catch problems early, reducing the risk of costly repairs and downtime. A preventive maintenance schedule should include tasks such as regular cleaning, component inspection, and performance monitoring. By implementing a preventive maintenance schedule, you can help minimize downtime and reduce repair costs.

Tip 2: Proper Alignment

Proper alignment of components is critical for preventing vibrations and reducing stress on the system. Misaligned components can cause vibrations, which can lead to premature wear and tear, and even catastrophic failure. Regular alignment checks can help ensure that components are properly aligned, reducing the risk of vibrations and improving overall system performance. For example, a study by the Society of Automotive Engineers found that proper alignment can reduce vibrations by up to 90% and improve fuel efficiency by up to 15%.

Upgrading to High-Efficiency Components

Upgrading to high-efficiency components can help reduce energy consumption and improve overall system performance. High-efficiency components, such as high-efficiency motors and low-friction bearings, can help reduce energy consumption and improve overall system performance. By upgrading to high-efficiency components, you can help reduce your energy bills and improve the overall performance and lifespan of your mechanical system.

Tip 3: Regular Inspection and Maintenance

Regular inspection and maintenance are critical for identifying potential issues before they become major problems. Regular inspection can help you catch problems early, reducing the risk of costly repairs and downtime. Maintenance tasks, such as regular cleaning and component replacement, can help ensure that your mechanical system is running smoothly and efficiently.

Minimizing Downtime

Downtime can be costly and debilitating for any organization. By implementing a preventive maintenance schedule and upgrading to high-efficiency components, you can help minimize downtime and reduce repair costs. Regular inspection and maintenance can help identify potential issues before they become major problems, reducing the risk of costly repairs and downtime.

Tip 4: Upgrading to High-Efficiency Components

Upgrading to high-efficiency components can help reduce energy consumption and improve overall system performance. High-efficiency components, such as high-efficiency motors and low-friction bearings, can help reduce energy consumption and improve overall system performance. By upgrading to high-efficiency components, you can help reduce your energy bills and improve the overall performance and lifespan of your mechanical system.

Tip 5: Implementing a Preventive Maintenance Schedule

Implementing a preventive maintenance schedule can help minimize downtime and reduce repair costs. A preventive maintenance schedule should include tasks such as regular cleaning, component inspection, and performance monitoring. By implementing a preventive maintenance schedule, you can help identify potential issues before they become major problems, reducing the risk of costly repairs and downtime.

What is the most critical maintenance task for mechanical systems?

+Regular lubrication is the most critical maintenance task for mechanical systems. Without proper lubrication, components can overheat, corrode, or wear down prematurely, leading to costly repairs and downtime.

How often should I inspect my mechanical system?

+You should inspect your mechanical system regularly, ideally every 1,000 to 5,000 miles, depending on the type of system and its usage. Regular inspection can help identify potential issues before they become major problems, reducing the risk of costly repairs and downtime.

What are the benefits of upgrading to high-efficiency components?

+Upgrading to high-efficiency components can help reduce energy consumption, improve overall system performance, and extend the lifespan of your mechanical system. High-efficiency components, such as high-efficiency motors and low-friction bearings, can help reduce energy consumption and improve overall system performance.

Meta Description: Improve the efficiency, reliability, and lifespan of your mechanical systems with these five expert tips. Learn how regular lubrication, proper alignment, regular inspection and maintenance, upgrading to high-efficiency components, and implementing a preventive maintenance schedule can help minimize downtime and reduce repair costs. (145 characters)