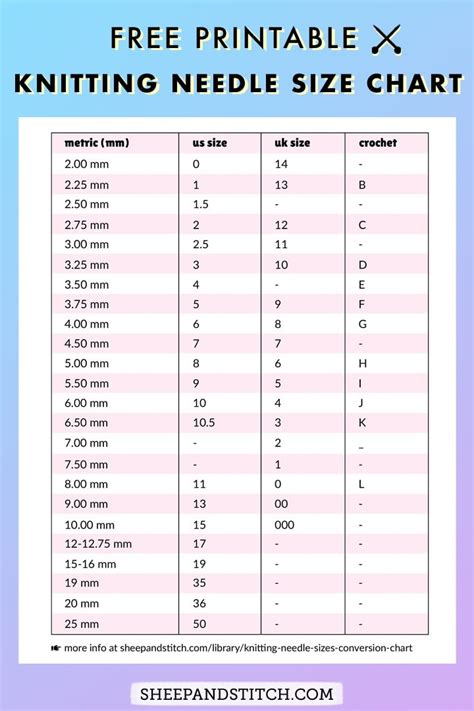

The world of needle gauge sizes can be complex and nuanced, especially for those who are new to the field of medical devices, sewing, or other applications where needles are used. To understand the intricacies of needle gauge sizes, it's essential to first grasp the basics of how gauges are measured and categorized. In this context, the term "gauge" refers to the diameter of the needle, with higher gauge numbers indicating smaller diameters and lower gauge numbers indicating larger diameters.

This inverse relationship between gauge numbers and needle diameters can seem counterintuitive at first, but it's a standard convention in the industry. The gauge system is based on the Stubs Iron Wire Gauge, which was originally developed for measuring the thickness of iron wire. Over time, this system has been adapted for use in various fields, including medicine, textiles, and more. Understanding the historical context and evolution of the gauge system can provide valuable insights into its application and interpretation.

Primary Considerations in Needle Gauge Sizes

When selecting a needle for a specific application, several factors must be considered, including the type of material being worked with, the desired outcome, and the potential risks associated with needle use. For instance, in medical settings, the choice of needle gauge size can have significant implications for patient safety and the effectiveness of treatments. Similarly, in sewing and embroidery, the right needle gauge can make a substantial difference in the quality and durability of the finished product.

The relationship between needle gauge size and the material being worked with is particularly important. Thicker materials generally require larger gauge needles to ensure smooth penetration and minimize the risk of breakage or damage. Conversely, thinner materials can be worked with smaller gauge needles, which provide more precision and control. This delicate balance between needle size and material thickness is crucial for achieving optimal results in various applications.

Gauge Size Ranges and Applications

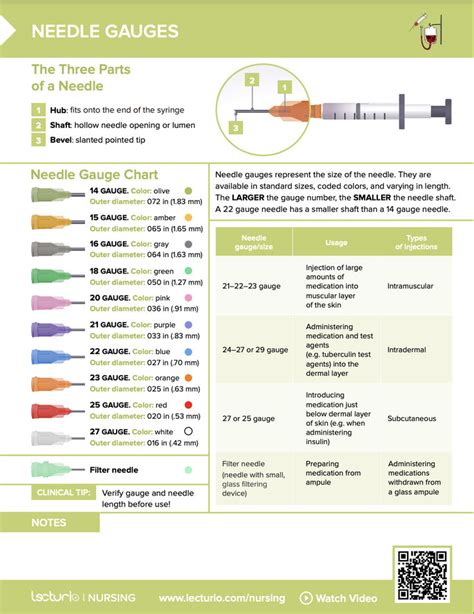

Needle gauge sizes span a wide range, from very fine (high gauge numbers) to very coarse (low gauge numbers). The specific range of gauge sizes used can vary significantly depending on the application. For example, in medical contexts, needles can range from 7 gauge (thick) to 33 gauge (very thin), with each size suited to particular procedures and patient needs. In contrast, sewing needles might range from 8 gauge to 20 gauge, with the choice of size depending on factors like fabric type, thread weight, and desired stitch quality.

The following table illustrates some common gauge sizes and their typical applications:

| Gauge Size | Application |

|---|---|

| 7-10 gauge | Heavy-duty sewing, leatherwork |

| 11-14 gauge | General sewing, quilting |

| 15-18 gauge | Delicate fabrics, embroidery |

| 19-22 gauge | Medical applications, vaccinations |

| 23-26 gauge | Intramuscular injections, blood sampling |

| 27-30 gauge | Subcutaneous injections, insulin administration |

| 31-33 gauge | Very fine, specialized medical procedures |

Key Considerations for Selecting the Right Needle Gauge Size

Selecting the appropriate needle gauge size involves careful consideration of several key factors, including the type of material, the desired outcome, and the potential risks associated with needle use. It's also important to consider the needle's length, as longer needles may be necessary for thicker materials or for reaching deeper tissue in medical applications. The point style of the needle is another critical factor, as different points are suited to different types of materials and tasks.

In medical settings, healthcare professionals must carefully evaluate the patient's specific needs and the requirements of the procedure when choosing a needle gauge size. This might involve considering factors like the patient's age, weight, and medical history, as well as the type of medication or treatment being administered. By taking a thoughtful and informed approach to needle selection, healthcare professionals can help ensure safe and effective outcomes for their patients.

Key Points

- Needle gauge sizes are inversely related to diameter, with higher gauge numbers indicating smaller diameters.

- The choice of needle gauge size depends on the application, including the type of material and the desired outcome.

- In medical contexts, needle gauge sizes range from 7 gauge to 33 gauge, with each size suited to particular procedures and patient needs.

- Considering factors like needle length and point style is crucial for optimal performance and safety.

- Healthcare professionals must carefully evaluate patient needs and procedure requirements when selecting a needle gauge size.

Future Directions and Implications

As technology continues to evolve, it's likely that new innovations in needle design and materials will emerge, offering improved performance, safety, and efficacy. The development of finer, more precise needles could expand the possibilities for delicate procedures and minimally invasive treatments. Additionally, advancements in materials science could lead to the creation of needles with unique properties, such as enhanced durability or reduced friction, which could further improve outcomes in various applications.

Looking ahead, it's essential to consider the potential implications of these advancements and how they might shape the future of needle use in medical, sewing, and other contexts. By staying informed about the latest developments and trends in needle technology, professionals and enthusiasts alike can stay ahead of the curve and capitalize on new opportunities for growth and innovation.

What is the relationship between needle gauge size and material thickness?

+Thicker materials generally require larger gauge needles to ensure smooth penetration and minimize the risk of breakage or damage. Conversely, thinner materials can be worked with smaller gauge needles, which provide more precision and control.

How do I choose the right needle gauge size for a medical procedure?

+Choosing the right needle gauge size for a medical procedure involves careful consideration of several key factors, including the type of material, the desired outcome, and the potential risks associated with needle use. It’s also essential to evaluate the patient’s specific needs and the requirements of the procedure.

What are some common applications for different needle gauge sizes?

+Needle gauge sizes are used in a variety of applications, including medical procedures, sewing, and embroidery. The specific gauge size used depends on the type of material, the desired outcome, and the potential risks associated with needle use. For example, thicker materials like leather may require larger gauge needles, while thinner materials like silk may require smaller gauge needles.