In recent years, the convenience and efficiency of fluid removal methods have significantly advanced, with the oil extractor pump emerging as a prominent tool benefiting industrial, automotive, and hobbyist applications alike. These devices, designed to streamline the process of extracting oils, fuels, and other liquids, have transformed traditional practices by offering a safer, cleaner, and more precise alternative to manual pouring or cumbersome siphoning techniques. Experts in mechanical engineering, automotive repair, and DIY mechanics recognize that integrating an oil extractor pump into routine maintenance routines enhances operational effectiveness while reducing labor and mess. As technology continues to evolve, understanding the core advantages of utilizing an oil extractor pump becomes essential not only for professionals but also for enthusiasts seeking optimized workflows. This detailed exploration underscores the top ten benefits that make these devices indispensable in fluid management processes.

Key Points

- Enhanced safety: Minimizes exposure to hazardous fluids, reducing health risks during fluid removal.

- Time efficiency: Accelerates fluid extraction, cutting down labor hours significantly.

- Clean operation: Reduces spillage and mess, promoting a neater workspace or environment.

- Precision control: Offers accurate fluid retrieval, instrumental in sensitive applications where contamination or loss must be minimized.

- Versatility: Supports multiple fluids including oils, gasoline, and coolants, adaptable to various industries and DIY tasks.

The Role of Oil Extractor Pumps in Modern Maintenance and Industry

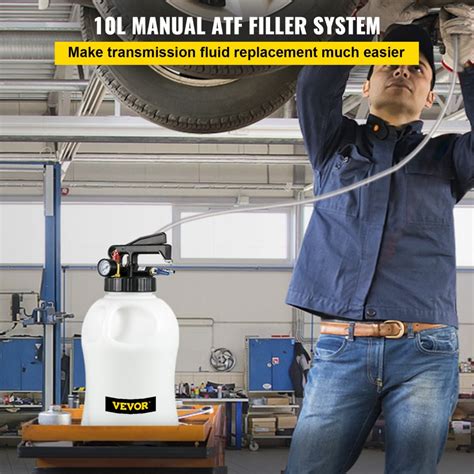

Oil extractor pumps are increasingly recognized as fundamental tools that revolutionize fluid handling in several key sectors. In automotive maintenance, especially, these devices simplify oil changes by providing a swift, mess-free alternative to traditional draining methods. Additionally, in industrial settings, such pumps facilitate rapid removal of lubricants, chemicals, and fuels from tanks or machinery, thereby minimizing downtime and improving safety standards. They are particularly valued in environments where fluid contamination must be rigorously controlled or where manual siphoning presents safety hazards. For hobbyists and small-scale repair shops, investing in a portable oil extractor pump enhances workflow efficiency and reduces the physical strain associated with manual fluid transfer.

Comprehensive Benefits of Using an Oil Extractor Pump

1. Improved Safety Profile

Safety remains paramount in any fluid management operation, especially when handling potentially hazardous substances like gasoline, engine oil, or other chemicals. Traditional methods, such as siphoning or draining into open containers, increase the risk of spills, accidental contact, and inhalation of fumes. Oil extractor pumps mitigate these risks by providing a sealed and controlled environment for fluid transfer. With automatic shutoff features and the ability to operate without tilting or tipping tanks, operators reduce their exposure to dangerous vapors and liquids. This benefit is particularly advantageous where environmental or health regulations impose strict safety standards, making the use of extractor pumps not only more convenient but also compliant with safety directives.

2. Significant Time and Labor Savings

Time efficiency is a crucial consideration, especially in professional settings that demand high throughput. Manual draining or siphoning can be time-consuming, often requiring multiple steps and constant supervision to prevent spills. Oil extractor pumps, especially electric or battery-powered models, drastically cut downtime. For instance, a typical automotive oil change using a traditional method might take 30–45 minutes, but with a high-quality extractor pump, the process can be completed in under 10 minutes. Industry data illustrates that using these pumps can reduce labor hours by up to 50%, translating into tangible cost savings and increased productivity in commercial operations.

3. Cleaner and More Precise Fluid Removal

Mess and spills are common drawbacks of manual fluid extraction techniques. These not only pose safety hazards but also contribute to environmental pollution and increased cleanup efforts. Oil extractor pumps provide a cleaner alternative by utilizing sealed hoses and transparent reservoirs that enable precise control over fluid volume. Their design minimizes spillage, ensuring a neat workspace and reducing waste. Furthermore, the ability to regulate flow rate and stopping points enhances accuracy, critical in applications where over-removal could damage equipment or diminish fluid levels inadvertently. In sensitive contexts like laboratory settings or high-precision machinery, this level of control is invaluable.

4. Versatility Across Fluids and Applications

One of the standout qualities of modern oil extractor pumps is their versatility. Various models support a range of fluids, from engine oils and transmission fluids to gasoline, coolant, or even certain chemicals used in manufacturing. This multifunctionality extends their utility across sectors such as automotive repair, aviation, small-scale manufacturing, and environmental remediation. For example, specialized pumps with compatible materials prevent corrosion or chemical reactions with particular substances, expanding their application scope. Such adaptability makes them essential tools for diverse fluid handling tasks, offering a single solution adaptable to shifting requirements.

5. Cost-effectiveness and Long-term Investment

While the initial purchase price of a quality oil extractor pump may appear significant, the long-term savings justify the investment. These devices extend the lifespan of maintenance tools by reducing wear on manual labor and minimizing consumables like disposable containers or absorbent pads. Additionally, reducing spills prevents environmental fines and cleanup costs, especially for businesses subject to strict regulations. When factoring in the decreased labor hours, lower risk of accidents, and improved efficiency, an oil extractor pump emerges as a cost-effective upgrade that pays for itself over time through operational savings.

Technical Aspects and Selection Criteria

Choosing the right oil extractor pump involves evaluating several technical specifications, including flow rate, hose length, compatibility with fluids, and power source. For instance, a pump with a flow rate exceeding 1 liter per minute ensures swift operation, especially in larger tanks or engines. Hose length must balance portability with reach, typically ranging from 1 to 3 meters in most models. Material construction—such as BPA-free plastics or corrosion-resistant metals—ensures durability and safety. Power options vary from manual hand-operated levers to electric motors powered by 12V car batteries or mains electricity. Users must consider their specific application environment, flow capacity needs, and budget when selecting a device.

| Relevant Category | Substantive Data |

|---|---|

| Flow Rate | Typically 0.5-2 liters per minute, depending on model and fluid viscosity |

| Hose Length | Standard 1-3 meters, adjustable in many models for flexibility |

| Power Type | Manual, battery-powered, or mains electric options |

| Material Compatibility | High-density polyethylene, polypropylene, and stainless steel components for chemical resistance |

Potential Limitations and Considerations

Despite their numerous benefits, oil extractor pumps are not universally flawless. Limitations include potential for hose clogging or failure when handling highly viscous or contaminated fluids. Some models may struggle with thick oils or sludge, necessitating maintenance or pre-filtering steps. Furthermore, electric pumps require reliable power sources, which may limit their usability in remote or off-grid locations. Cost considerations should also be balanced against anticipated usage volume—occasional DIY users might opt for manual models, while large workshops benefit from high-capacity, automated devices. Awareness of these limitations encourages informed purchasing decisions and ensures safe, effective operation.

Future Trends in Fluid Extraction Technology

The evolution of oil extractor pumps continues, driven by advances in automation, materials science, and digital integration. Emerging models incorporate smart sensors for real-time flow monitoring and automatic shutoff to prevent over-extraction. Wireless, battery-powered devices with longer operational life and faster charging capabilities are on the horizon, increasing portability and convenience. Additionally, environmentally friendly materials and energy-efficient motors reflect industry commitments to sustainable practices. These trends promise to further embed oil extractor pumps into a broad spectrum of applications, from detailed laboratory procedures to large-scale industrial maintenance, elevating standard operational practices.

Conclusion: Embracing the Efficiency of Oil Extractor Pumps

In summary, the top ten benefits of employing an oil extractor pump encompass safety, efficiency, cleanliness, precision, versatility, cost-effectiveness, and ongoing technological enhancements. These devices stand out as pivotal tools that streamline fluid management processes across various sectors, reducing risks and labor while improving accuracy and environmental compliance. As industries increasingly focus on safety standards and operational excellence, integrating high-quality oil extractor pumps aligns with broader goals of innovation and sustainability. Whether in professional service centers or DIY garages, their role in modern fluid handling is truly transformative, embodying a blend of engineering ingenuity and practical necessity.

What distinguishes electric oil extractor pumps from manual models?

+Electric models offer faster flow rates, consistent operation, and require less physical effort, making them ideal for high-volume or frequent use. Manual pumps depend on hand operation, providing greater control but at a slower pace, suitable for occasional tasks or when power sources are unavailable.

Are oil extractor pumps suitable for all types of fluids?

+Most models are compatible with standard petroleum-based fluids like engine oil, gasoline, and coolants. However, highly viscous or contaminated fluids may require specialized pumps designed to handle such conditions, and users should always verify the material compatibility to prevent damage or leaks.

How can I ensure the safety when operating an oil extractor pump?

+Always wear protective gear, operate in well-ventilated areas, and follow manufacturer instructions. Use sealed, leak-proof containers, and ensure the pump’s safety features—like shutoff valves—are functioning. Regular maintenance and inspection also help prevent accidental spills or malfunctions.