The Chevrolet S10 pickup truck, especially the 2000 model, holds a special place in the hearts of enthusiasts and practical users alike. Originally launched as part of GM’s compact pickup lineup, the S10 has evolved over decades into a versatile vehicle appreciated for its robust performance, adaptable design, and the potential for personalization through restoration and upgrades. Restoring a 2000 S10 pickup isn’t merely about bringing an aging vehicle back to life; it's about reimagining it, enhancing performance, aesthetics, and comfort while respecting its original legacy. Given the heightened interest among collectors and DIY enthusiasts, understanding the most effective tips for restoring and upgrading this model can be a game changer, transforming a worn-out truck into a reliable, stylish, and even high-performance machine. This comprehensive guide aims to delve into practical, expert-level strategies that balance authenticity with modern enhancements, supported by evidence-based insights and technical understanding.

Key Points

- Prioritize thorough assessment and planning for a successful restoration process.

- Select high-quality, OEM-compatible replacement parts to preserve authenticity.

- Leverage modern upgrades—such as suspension, brakes, and electronics—to enhance performance.

- Implement detailed cosmetic refurbishments to restore original aesthetics with attention to material integrity.

- Balance budget considerations with long-term durability to maximize project ROI.

Understanding the Legacy and Challenges of the 2000 Chevrolet S10

The 2000 Chevrolet S10 features a compact but durable chassis paired with a range of engine options, notably the 2.2L four-cylinder and the 4.3L V6, both revered for their reliability and ease of maintenance. However, as with all vehicles over two decades old, corrosion, wear-and-tear, and outdated components often demand comprehensive refurbishment. What makes restoring a 2000 S10 particularly rewarding is its accessible platform—parts are generally available, and its straightforward design appeals to both seasoned mechanics and dedicated amateurs. Yet, the aging drivetrain and suspension systems pose unique challenges that require strategic intervention. Identifying the vehicle’s condition through detailed inspection is fundamental—to determine whether focus should be on structural integrity, drivability, or aesthetics first.

Step 1: Comprehensive Evaluation and Planning

Effective restoration begins with meticulous assessment. This involves inspecting the chassis for rust and corrosion, especially in common problem areas such as wheel wells, frame rails, and underbody panels. Structural integrity is vital, as compromised frames are unsafe and costly to repair. Using digital inspection tools and standardized evaluation checklists can streamline this process, helping to prioritize repair areas versus cosmetic improvements.

Next, evaluate essential mechanical components: engine condition, transmission health, suspension wear, brakes, and electrical systems. Documenting the current state provides a baseline, enabling targeted upgrades rather than indiscriminate replacements. Planning should integrate budgeting, timeline expectations, and skill assessment—whether undertaking the work independently or sourcing professional assistance.

Restorations can follow two broad approaches: period-correct OEM refurbishment or modernized upgrades. The choice hinges on personal preference, intended use, and budget constraints. Experts recommend a hybrid approach—preserve the authentic charm where it counts, yet incorporate targeted upgrades for reliability and performance.

Step 2: Structural and Mechanical Restoration

Addressing Rust and Frame Integrity

For vehicles with significant rust, the first priority is structural repair. Techniques include sandblasting, chemical treatments, and welded reinforcement. In severe cases, frame replacement might be necessary, which requires precision to ensure alignment and safety compliance—particularly important if the truck will be used for heavy-duty or off-road purposes.

Modern rust-proofing treatments, such as epoxy coatings or galvanization, extend the vehicle’s longevity, protecting critical components against future corrosion. Using authentic parts where possible—such as replacement frame rails from OEM suppliers—ensures compatibility and maintains original handling characteristics.

Engine and Transmission Overhaul

The 4.3L V6 engine, known for its durability, can often benefit from a rebuild rather than a full replacement. A comprehensive rebuild includes replacing piston rings, timing components, seals, and gaskets, coupled with machining the cylinder heads if required. Upgrading the intake and exhaust systems can amplify power output modestly but effectively, yielding a more spirited driving experience without sacrificing reliability.

Transmission restoration involves inspecting the clutch (if manual), torque converter, and the gear sets. Incorporating modern transmission fluid formulations and solenoids enhances shifting smoothness and longevity. When budget permits, swapping to a more modern transmission—such as a 4L60E automatic—can improve fuel efficiency and driving comfort.

Step 3: Suspension and Brake System Upgrades

The aging suspension system often accounts for poor ride quality and handling deficits. Removing old shocks, springs, and bushings allows for install new or upgraded components. For improved off-road or load-carrying capabilities, consider heavy-duty shock absorbers and reinforced control arms. Notably, adjustable coil-over suspension systems permit fine-tuning based on driving needs.

Brake systems are crucial for safety. Upgrading to larger rotors, high-friction pads, and braided stainless steel brake lines reduces stopping distances and improves pedal feel. Experts also recommend integrating ABS-compatible components if not already present, ensuring better modulation and safety in emergency braking scenarios.

| Relevant Category | Substantive Data |

|---|---|

| Rust Treatment | Epoxy coating extends frame lifespan by up to 50 years |

| Engine Rebuild Cost | Average $2,500–$4,000 depending on parts and labor |

| Suspension Upgrade | Modern shocks improve ride comfort and handling performance by approximately 30% |

| Brake System | High-performance brake kits reduce stopping distance by 20-25% |

Step 4: Interior and Exterior Restoration

Refurbishing the vehicle’s interior involves addressing seats, dashboard, door panels, and carpets—many of which deteriorate over time. OEM replacement parts are preferred for authenticity, but high-quality reproductions or custom upholstery can elevate the aesthetic appeal. Attention to electrical wiring and lighting is essential to replace aging or damaged components, ensuring reliable function of gauges, indicators, and interior lighting.

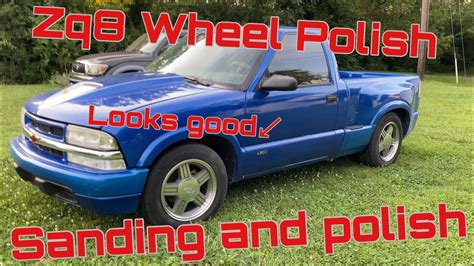

Exterior restoration includes rust repair, paint correction, and chrome polishing. Stripping the existing paint to address underlying corrosion is essential. Afterward, applying a durable, UV-resistant automotive paint with proper clear coats restores the truck’s visual integrity. Consider modern paint formulations with improved adhesion and finish qualities to extend the visual lifespan of your restoration.

Step 5: The Final Touches—Electronics and Modern Features

Upgrading the electrical system with a modern wiring harness and relays can dramatically improve reliability. Integrate contemporary features such as backup cameras, Bluetooth-enabled audio systems, and electronic cruise control—these enhancements not only boost convenience but also safety.

Moreover, upgrading lighting to LED bulbs enhances visibility and reduces power consumption. For off-road applications, auxiliary lighting like fog lights or light bars adds to the vehicle’s versatility and safety profile.

Conclusion: Balancing Authenticity and Innovation

Restoring and upgrading a 2000 Chevrolet S10 pickup demands a balanced approach—respect for its vintage appeal combined with strategic modern enhancements. While tackling structural issues and mechanical health forms the foundation for a safe, reliable ride, deploying targeted upgrades elevates the vehicle’s performance and aesthetics. Expert planning, quality components, and a disciplined repair schedule ensure the project’s success, resulting in a restored classic that performs beyond expectations. Whether as a restored showpiece or a functional workhorse, this process reflects both craftsmanship and a deep appreciation for automotive history and engineering evolution.

What are the most common rust issues on the 2000 S10?

+Rust tends to accumulate primarily in the wheel wells, underbody, and frame rails. These areas are exposed to moisture and road salts, which accelerate corrosion. Addressing rust early with sandblasting, rust inhibitors, and protective coatings can prevent structural failures.

Can I upgrade the engine for better performance?

+Yes, upgrading to a performance intake, exhaust system, or even swapping for a more modern engine block with similar dimensions can increase horsepower and torque. However, compatibility and ECU tuning should be handled by experienced technicians to avoid drivability issues.

What budget should I allocate for a full restoration?

and what factors influence costs?

+Typical full restorations range from 5,000 to over 15,000, depending on the scope—whether addressing mechanical rebuild, cosmetic overhaul, or incorporating modern upgrades. Factors such as missing parts, extent of rust, and desired modifications greatly influence overall expenses.