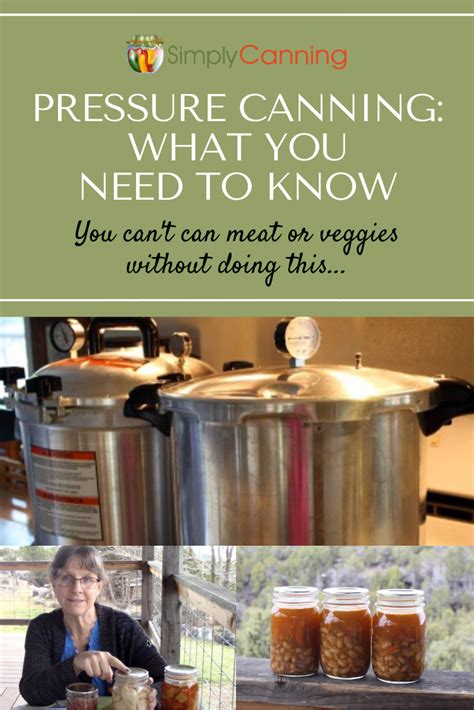

Pressure canning is a crucial method for preserving food, especially for low-acid foods like meats, vegetables, and soups. One of the most critical components of pressure canning is understanding and managing pressure. The pressure canner pressure guide is essential for ensuring that food is heated to a sufficient temperature to kill off harmful bacteria and other microorganisms, while also preventing spoilage and maintaining the quality of the food. In this article, we will delve into the world of pressure canning, exploring the importance of pressure, the different types of pressure canners, and providing a comprehensive guide to pressure canner pressures.

Key Points

- Understanding pressure canner pressures is crucial for safe and effective food preservation.

- Different types of pressure canners have varying pressure requirements.

- Altitude and temperature affect pressure canner pressures.

- Regular maintenance and testing of pressure canners are essential for ensuring accurate pressures.

- Consulting a reliable pressure canner pressure guide is vital for achieving optimal canning results.

Introduction to Pressure Canners

Pressure canners are specialized pots designed to withstand high pressures and temperatures, making them ideal for canning low-acid foods. There are several types of pressure canners available, including dial-gauge canners, weighted-gauge canners, and electric canners. Each type of canner has its unique characteristics, advantages, and pressure requirements. For instance, dial-gauge canners rely on a dial to indicate the pressure, while weighted-gauge canners use a weighted regulator to control the pressure.

Understanding Pressure Canner Pressures

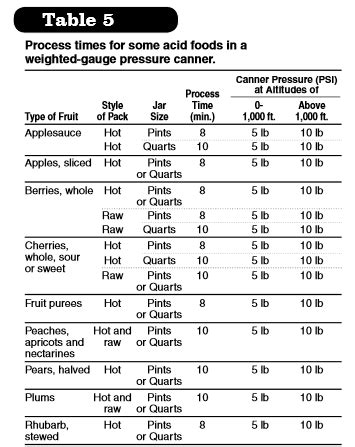

Pressure canner pressures are measured in pounds per square inch (PSI). The ideal pressure for canning varies depending on the type of food, altitude, and desired level of doneness. Generally, pressure canners operate at pressures between 5 and 15 PSI. However, it’s essential to consult a reliable pressure canner pressure guide to determine the exact pressure requirements for your specific canning needs. For example, canning green beans at 10 PSI can ensure that they are heated to a sufficient temperature to kill off harmful bacteria, while also preserving their texture and flavor.

| Food Type | Pressure (PSI) | Processing Time (minutes) |

|---|---|---|

| Green Beans | 10 | 20-30 |

| Meat (Beef, Pork, Lamb) | 10-15 | 30-60 |

| Vegetables (Carrots, Peas, Corn) | 5-10 | 10-30 |

Factors Affecting Pressure Canner Pressures

Several factors can affect pressure canner pressures, including altitude, temperature, and the type of canner being used. At higher altitudes, the air pressure is lower, which can affect the pressure canner’s performance. Temperature also plays a crucial role, as higher temperatures can increase the pressure inside the canner. It’s essential to adjust the pressure canner’s pressure accordingly to ensure that the food is heated to a sufficient temperature to kill off harmful bacteria. For instance, at high altitudes, you may need to increase the pressure to 12 PSI to ensure that the food is properly sterilized.

Altitude Adjustments

When canning at high altitudes, it’s essential to adjust the pressure canner’s pressure to compensate for the lower air pressure. A general rule of thumb is to increase the pressure by 1 PSI for every 1,000 feet of altitude. However, it’s crucial to consult a reliable pressure canner pressure guide to determine the exact pressure requirements for your specific altitude and canning needs. For example, if you’re canning at an altitude of 5,000 feet, you may need to increase the pressure to 12 PSI to ensure that the food is properly sterilized.

| Altitude (feet) | Pressure Adjustment (PSI) |

|---|---|

| 0-1,000 | 0 |

| 1,001-2,000 | 1 |

| 2,001-3,000 | 2 |

| 3,001-5,000 | 3 |

Maintenance and Testing of Pressure Canners

Regular maintenance and testing of pressure canners are essential for ensuring accurate pressures and safe canning practices. It’s crucial to check the canner’s gasket, valve, and other components regularly to ensure they’re in good working condition. Additionally, testing the canner’s pressure gauge periodically can help identify any potential issues. A well-maintained pressure canner is essential for achieving optimal canning results and ensuring the safety of the food being preserved.

Testing Pressure Canners

Testing pressure canners involves checking the pressure gauge to ensure it’s accurate and functioning correctly. This can be done by attaching a test gauge to the canner and comparing the readings. It’s also essential to check the canner’s valve and gasket for any signs of wear or damage. Regular testing and maintenance can help prevent potential issues and ensure that the pressure canner is operating at optimal levels. For instance, if the pressure gauge is inaccurate, it can lead to under- or over-processing of the food, which can affect its safety and quality.

What is the ideal pressure for canning green beans?

+The ideal pressure for canning green beans is 10 PSI, with a processing time of 20-30 minutes.

How do I adjust the pressure canner's pressure for high altitude?

+A general rule of thumb is to increase the pressure by 1 PSI for every 1,000 feet of altitude. However, it's crucial to consult a reliable pressure canner pressure guide to determine the exact pressure requirements for your specific altitude and canning needs.

Why is regular maintenance and testing of pressure canners important?

+Regular maintenance and testing of pressure canners are essential for ensuring accurate pressures and safe canning practices. This helps prevent potential issues and ensures that the pressure canner is operating at optimal levels.

Meta description: Learn how to use a pressure canner with our comprehensive guide, covering pressure canner pressures, altitude adjustments, and maintenance tips for safe and effective food preservation.