The concept of grain and its impact on relaxation times is a complex and multifaceted topic, spanning various disciplines such as materials science, physics, and engineering. At its core, grain refers to the microscopic crystal structure that makes up the bulk of many materials, including metals, ceramics, and even some biological tissues. The size, shape, and distribution of these grains can significantly influence the physical, mechanical, and thermal properties of a material. One critical aspect where grain plays a pivotal role is in the relaxation times of materials, which are essential for understanding how materials respond to external stresses, thermal fluctuations, and other environmental changes. Relaxation times are a measure of how quickly a material returns to its equilibrium state after being disturbed. In this context, the impact of grain on relaxation times can be understood through several key mechanisms.

Key Points

- The size and distribution of grains within a material can significantly affect its thermal conductivity, with smaller grains typically leading to lower thermal conductivity due to increased grain boundary scattering.

- Grain boundaries can act as sinks for defects and impurities, influencing the material's electrical conductivity and potentially affecting its relaxation times in response to electrical stimuli.

- The mechanical properties of a material, such as its strength and ductility, are influenced by grain size, with finer grains often resulting in stronger but less ductile materials.

- Grain orientation and anisotropy can have a profound impact on the relaxation times of materials under different types of external stimuli, including magnetic fields and mechanical stress.

- The dynamics of grain growth and recrystallization can significantly alter a material's microstructure over time, thereby changing its relaxation behavior in response to thermal treatments or mechanical working.

Influence of Grain Size on Thermal Relaxation

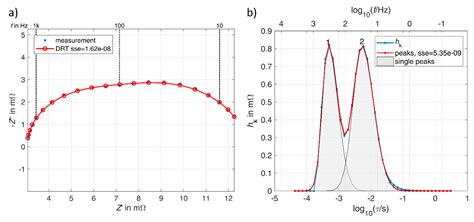

One of the primary ways grain impacts relaxation times is through its influence on thermal conductivity. Smaller grains lead to increased grain boundary area per volume, which can significantly impede heat transfer due to the scattering of phonons at grain boundaries. This phenomenon is particularly relevant in polycrystalline materials, where the grain size distribution can vary widely. For instance, in the context of thermoelectric materials, optimizing grain size is crucial for achieving high figures of merit, which depend on the material’s ability to conduct heat and electricity efficiently. Experimental studies have shown that reducing grain size can lead to enhanced thermoelectric performance by reducing thermal conductivity without severely impacting electrical conductivity.

Grain Boundary Effects on Electrical Relaxation

Grain boundaries can also play a critical role in the electrical relaxation of materials. These boundaries can act as defects or traps for charge carriers, influencing the material’s electrical conductivity. In semiconducting materials, for example, grain boundaries can significantly affect the carrier mobility and lifetime, thereby influencing the relaxation times of electrical signals. Research in photovoltaic materials has highlighted the importance of controlling grain size and boundary properties to optimize device efficiency, as large grains with clean boundaries can reduce recombination losses and enhance charge carrier collection.

| Material Property | Influence of Grain Size |

|---|---|

| Thermal Conductivity | Decreases with smaller grain size due to increased scattering |

| Electrical Conductivity | Can decrease with smaller grain size due to grain boundary defects |

| Mechanical Strength | Generally increases with smaller grain size due to Hall-Petch relationship |

Grain Orientation and Anisotropy Effects

The orientation and anisotropy of grains within a material can also have a profound impact on its relaxation times. In materials with significant anisotropy, such as wood or certain composites, the direction of the grain relative to an external stimulus (like a magnetic field or mechanical stress) can dramatically affect the material’s response. Studies on magnetic materials have shown that grain orientation can influence the coercivity and remanence of the material, thereby affecting its magnetic relaxation behavior. Similarly, in the context of mechanical properties, the anisotropy introduced by grain orientation can lead to variations in strength and ductility depending on the loading direction.

Dynamics of Grain Growth and Recrystallization

The microstructure of a material, including its grain size and distribution, is not static and can evolve over time due to processes like grain growth and recrystallization. These dynamic processes can be triggered by thermal treatments, mechanical working, or other forms of energy input. Understanding the kinetics of grain growth and the conditions under which recrystallization occurs is crucial for predicting how a material’s relaxation times might change over its lifespan. Investigations into the recrystallization behavior of deformed metals, for instance, have highlighted the importance of controlling thermal treatments to achieve desired grain structures and, by extension, tailored relaxation properties.

How does grain size affect the thermal conductivity of a material?

+Smaller grain sizes lead to increased grain boundary area, which can scatter phonons and reduce thermal conductivity. This effect is more pronounced in materials with high grain boundary densities.

What role do grain boundaries play in electrical relaxation?

+Grain boundaries can act as traps for charge carriers, influencing the material's electrical conductivity and relaxation times. Optimizing grain boundary properties is crucial for achieving high efficiency in devices like solar cells.

How does grain orientation affect the mechanical properties of a material?

+The orientation of grains relative to the loading direction can significantly affect a material's strength and ductility. Materials with anisotropic grain structures may exhibit varying properties depending on the direction of loading.

In conclusion, the impact of grain on relaxation times in materials is multifaceted and depends on various factors, including grain size, orientation, and the dynamic processes that alter the material’s microstructure over time. Understanding these relationships is crucial for designing and optimizing materials for specific applications, where tailored relaxation properties can significantly enhance performance and efficiency. By considering the complex interplay between grain structure and material properties, researchers and engineers can develop innovative solutions that exploit the unique characteristics of grains to achieve desired relaxation behaviors.