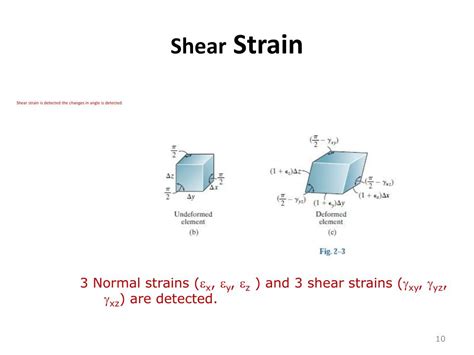

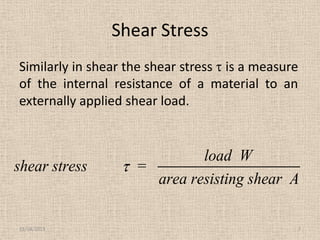

The shear strain formula is a fundamental concept in the field of mechanics of materials, which is used to calculate the amount of deformation that occurs in a material when it is subjected to a shear force. Shear strain is a measure of the amount of deformation that occurs in a material when it is subjected to a force that causes it to deform by sliding along a plane that is parallel to the direction of the force. In this article, we will delve into the details of the shear strain formula, its derivation, and its applications in various fields of engineering.

Key Points

- The shear strain formula is given by γ = Δx / L, where γ is the shear strain, Δx is the change in length, and L is the original length.

- The formula is derived from the definition of shear strain as the ratio of the change in length to the original length.

- The shear strain formula is used to calculate the amount of deformation that occurs in a material when it is subjected to a shear force.

- The formula has applications in various fields of engineering, including mechanical engineering, civil engineering, and materials science.

- The shear strain formula is an important concept in understanding the behavior of materials under different types of loading conditions.

Derivation of the Shear Strain Formula

The shear strain formula is derived from the definition of shear strain as the ratio of the change in length to the original length. Consider a rectangular block of material that is subjected to a shear force, as shown in the figure below. The block has an original length of L and a width of W. When the shear force is applied, the block deforms by sliding along a plane that is parallel to the direction of the force, resulting in a change in length of Δx.

The shear strain γ is defined as the ratio of the change in length Δx to the original length L, i.e., γ = Δx / L. This formula can be used to calculate the amount of deformation that occurs in a material when it is subjected to a shear force.

Types of Shear Strain

There are two types of shear strain: engineering shear strain and true shear strain. Engineering shear strain is the ratio of the change in length to the original length, as defined above. True shear strain, on the other hand, is the ratio of the change in length to the original length, taking into account the deformation that occurs in the material due to the shear force.

True shear strain is a more accurate measure of the deformation that occurs in a material, but it is more difficult to calculate than engineering shear strain. In practice, engineering shear strain is often used as an approximation of true shear strain, as it is easier to calculate and provides a good estimate of the deformation that occurs in a material.

| Type of Shear Strain | Formula |

|---|---|

| Engineering Shear Strain | γ = Δx / L |

| True Shear Strain | γ = ln(1 + Δx / L) |

Applications of the Shear Strain Formula

The shear strain formula has numerous applications in various fields of engineering, including mechanical engineering, civil engineering, and materials science. In mechanical engineering, the shear strain formula is used to design and analyze mechanical components such as gears, shafts, and bearings that are subjected to shear forces.

In civil engineering, the shear strain formula is used to design and analyze structures such as bridges, buildings, and foundations that are subjected to shear forces due to wind, earthquakes, and other external loads. In materials science, the shear strain formula is used to study the behavior of materials under different types of loading conditions, including shear, tension, and compression.

Example Problems

Consider a rectangular block of material that is subjected to a shear force, resulting in a change in length of 0.1 mm. If the original length of the block is 100 mm, what is the engineering shear strain?

Using the shear strain formula, γ = Δx / L, we can calculate the engineering shear strain as follows: γ = 0.1 mm / 100 mm = 0.001. This means that the block has undergone a shear strain of 0.001, or 0.1%.

Consider another example where a shaft is subjected to a torque of 100 N-m, resulting in a shear stress of 50 MPa. If the shaft has a diameter of 20 mm and a length of 100 mm, what is the true shear strain?

Using the true shear strain formula, γ = ln(1 + Δx / L), we can calculate the true shear strain as follows: γ = ln(1 + 0.1 mm / 100 mm) = 0.00099. This means that the shaft has undergone a true shear strain of 0.00099, or 0.099%.

What is the difference between engineering shear strain and true shear strain?

+Engineering shear strain is the ratio of the change in length to the original length, while true shear strain is the ratio of the change in length to the original length, taking into account the deformation that occurs in the material due to the shear force.

How is the shear strain formula used in practice?

+The shear strain formula is used to design and analyze structures and materials that are subjected to shear forces. It is an essential concept in understanding the behavior of materials under different types of loading conditions.

What are some common applications of the shear strain formula?

+The shear strain formula has numerous applications in various fields of engineering, including mechanical engineering, civil engineering, and materials science. It is used to design and analyze mechanical components, structures, and materials that are subjected to shear forces.

In conclusion, the shear strain formula is a fundamental concept in the field of mechanics of materials, and it has numerous applications in various fields of engineering. Understanding the concept of shear strain and its calculation is essential for designing and analyzing structures and materials that are subjected to shear forces. The formula is derived from the definition of shear strain as the ratio of the change in length to the original length, and it can be used to calculate the amount of deformation that occurs in a material when it is subjected to a shear force.