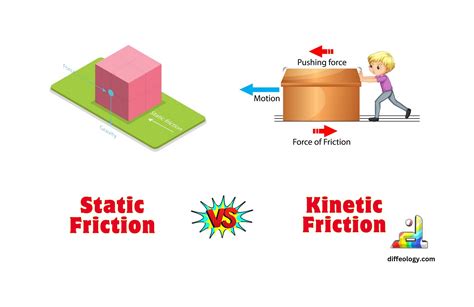

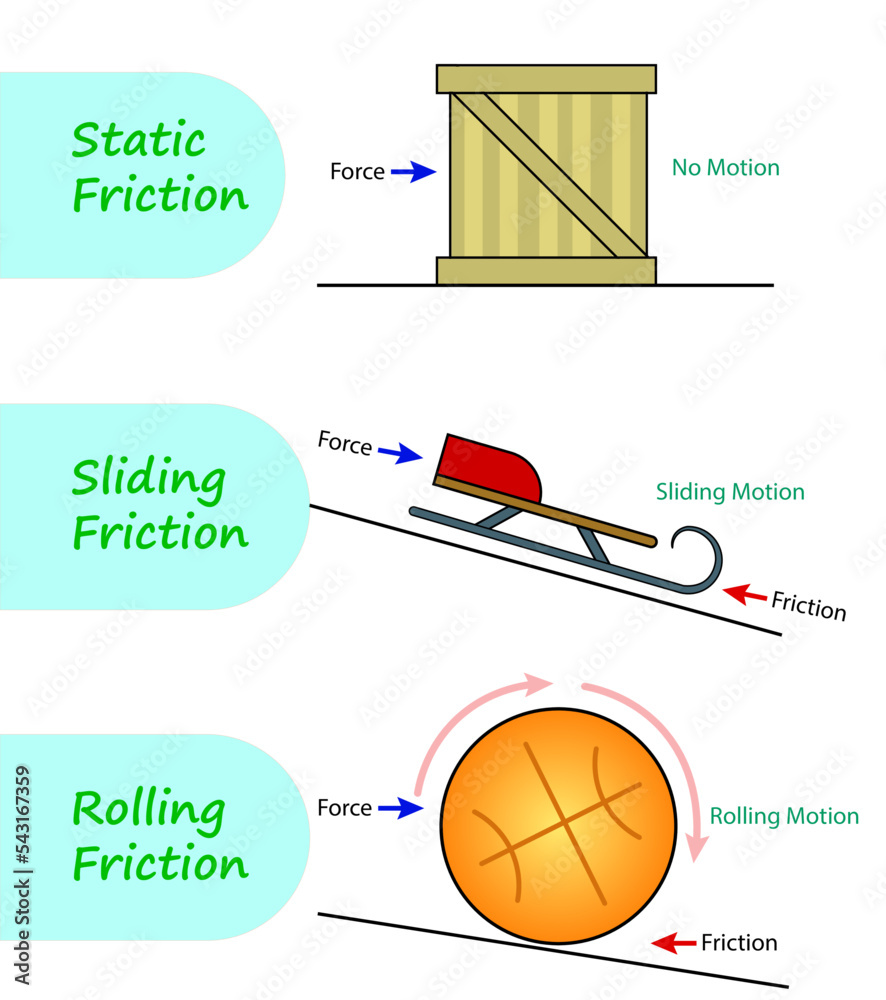

Static friction is a fundamental concept in physics that plays a crucial role in our daily lives, from walking and driving to designing and engineering various systems. It is the force that opposes the initiation of motion between two surfaces that are in contact with each other. Understanding and applying the principles of static friction can significantly enhance efficiency, safety, and performance in numerous applications. Here, we will delve into the concept of static friction, explore its significance, and provide actionable tips for leveraging its potential.

Key Points

- Understanding the concept of static friction and its importance in everyday applications

- Recognizing the factors that influence static friction, including surface roughness and normal force

- Applying static friction principles to enhance safety and efficiency in various contexts

- Utilizing materials and designs that optimize static friction for specific purposes

- Considering the limitations and potential drawbacks of relying on static friction in certain situations

Understanding Static Friction

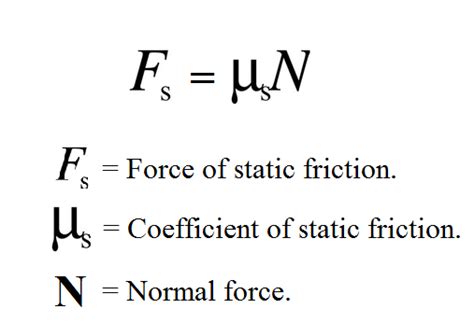

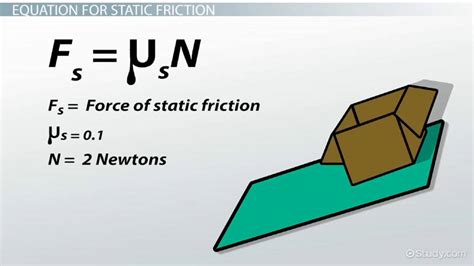

Static friction, often denoted as μs, is a measure of the maximum force that must be overcome to initiate motion between two stationary objects. It is influenced by the nature of the surfaces in contact, the normal force pressing these surfaces together, and the presence of any lubricants or contaminants. A deeper understanding of these factors can help in manipulating static friction to achieve desired outcomes, whether it’s to prevent slipping, ensure stable positioning, or facilitate smooth movement.

Factors Influencing Static Friction

The coefficient of static friction (μs) varies significantly depending on the materials involved. For instance, rubber on concrete has a higher μs than steel on steel, indicating a greater resistance to slipping. Moreover, increasing the normal force (the force perpendicular to the surfaces) enhances the static frictional force, as it increases the contact area and the interlocking of surface asperities. These principles are crucial in designing brakes, clutches, and other mechanical systems where control over motion initiation is critical.

| Material Combination | Coefficient of Static Friction (μs) |

|---|---|

| Rubber on Dry Concrete | 0.8 - 1.0 |

| Steel on Steel (Dry) | 0.6 - 0.8 |

| Wood on Wood | 0.25 - 0.5 |

Applying Static Friction Principles

Static friction plays a vital role in ensuring stability and control in various applications. In the context of vehicle safety, for example, the static friction between tires and the road surface is critical for preventing skidding and ensuring effective braking. Similarly, in construction, understanding and manipulating static friction is essential for the stability of structures and the safety of personnel and equipment.

Optimizing Static Friction

Optimizing static friction involves selecting materials and designing interfaces that achieve the desired level of frictional resistance. This can be done by increasing surface roughness, applying lubricants strategically, or utilizing texture and pattern designs that enhance interlocking between surfaces. In some cases, reducing static friction is beneficial, such as in the design of bearing systems where low friction coefficients are desirable for smooth and efficient operation.

In conclusion, static friction is a powerful force that can be harnessed and manipulated to achieve specific goals in engineering, safety, and performance. By understanding its principles and applying them thoughtfully, we can create more efficient, safer, and more reliable systems across a wide range of applications.

What is the primary factor influencing the coefficient of static friction?

+The primary factors include the nature of the surfaces in contact and the normal force pressing these surfaces together. However, the presence of lubricants, surface roughness, and environmental conditions also play significant roles.

How can static friction be optimized for specific applications?

+Static friction can be optimized by selecting appropriate materials, designing surfaces with specific textures or patterns, and strategically applying lubricants. Understanding the environmental conditions and how they affect static friction is also crucial.

What are the implications of ignoring static friction in system design?

+Ignoring static friction can lead to inefficient systems, reduced safety, and increased risk of accidents or failures. For example, underestimating the static friction between a vehicle’s tires and the road can result in skidding or inability to stop in time, while overestimating it can lead to unnecessary wear on components.