When it comes to working at heights, particularly on staircases, ladders, or elevated platforms, the importance of stability and safety cannot be overstated. Step ladder steps, often overlooked in their significance, are fundamental components that directly influence the integrity of the entire structure and the safety of the user. From professional construction sites to household maintenance, understanding the intricacies of step ladder steps—how they are designed, manufactured, and maintained—is essential for anyone aiming to minimize risks and improve operational efficiency. In this comprehensive guide, we will explore the technical aspects of step ladder steps, analyze industry standards, and provide best practices for ensuring optimal stability and safety during use. Drawing on expertise in occupational safety, mechanical engineering, and materials science, this article offers evidence-based insights, contextual examples, and practical recommendations tailored for professionals and serious DIY enthusiasts alike.

Understanding the Structural Foundation of Step Ladder Steps

The stability of a step ladder fundamentally depends on the sturdy construction and proper design of its individual steps. Typically crafted from durable materials such as aluminum, fiberglass, or reinforced steel, these steps are engineered to withstand significant load pressures while maintaining their shape and surface integrity. The core considerations include load capacity, slip resistance, material fatigue, and ease of maintenance.

Each step must support a safe working load, which is often specified by manufacturing standards such as ANSI (American National Standards Institute) and OSHA (Occupational Safety and Health Administration) requirements. For example, OSHA stipulates a minimum load capacity of 200 pounds for portable stepladders, which directly impacts the design specifications of individual steps. Materials used are selected not only for their strength-to-weight ratios but also for their resistance to environmental factors such as corrosion, moisture, and temperature variations.

Design Features Contributing to Stability

Key features of step ladder steps that influence overall stability include tread surface texture, tread width and depth, and attachment mechanisms. The tread surface often incorporates abrasive coatings or textured patterns—like knurling—to prevent slipping even when wet or greasy. The depth of the step is designed to distribute weight evenly, reducing pressure points that could cause bending or deformation.

Attachment mechanisms, such as rivets, welds, or slip-resistant plates, ensure that steps remain securely fastened to the side rails under load. Properly engineered attachment points prevent loosening over time, a common cause of instability. It’s worth noting that industry standards specify a minimum tread depth of 3 inches for safety purposes, with many commercial models opting for 4 to 5 inches for enhanced comfort and stability.

| Relevant Category | Substantive Data |

|---|---|

| Load Capacity | Minimum 200 pounds as per OSHA, with high-grade models supporting up to 375 pounds or more |

| Step Material | Aluminum alloys (e.g., 6061-T6) for lightweight strength, or reinforced fiberglass for electrical insulation |

| Surface Texture | Textured or abrasive coatings supporting slip-resistance ratings of R13 or higher |

The Evolution of Step Ladder Standards and Material Science

Over the past century, innovations in material science and manufacturing have profoundly influenced the safety standards of step ladder steps. Early wooden models, common in the 19th century, presented challenges such as cracking, splintering, and insufficient load capacity. The shift toward engineered aluminum alloys introduced lightweight yet robust alternatives capable of supporting rigorous industrial demands.

The introduction of fiberglass reinforcement further enhanced safety, particularly for electricians and workers exposed to live electrical environments, as fiberglass is inherently non-conductive. Advances in surface coating technologies—like powder coating and specialized anti-slip paints—have extended the durability and functional lifespan of ladder steps, even in harsh conditions.

Standards and certifications shaping modern design

Key standards such as ANSI A14.7 (for portable step ladders) and ISO 14122-3 (for fixed ladders) delineate specific criteria for step dimensions, load capacities, and safety features. Compliance with these standards ensures uniform safety profiles across different manufacturers and provides users with confidence in product reliability.

| Relevant Standard | Criteria |

|---|---|

| ANSI A14.7 | Requires non-slip treads, continuous structural integrity, and secure attachment mechanisms |

| ISO 14122-3 | Specifies safety requirements for fixed ladders, including step design and spacing |

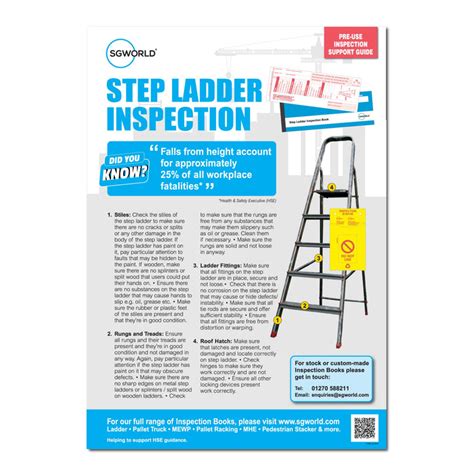

Maintenance and Inspection: Ensuring Longevity and Safety of Step Ladder Steps

Proper maintenance extends the functional lifespan of step ladder steps and mitigates potential hazards. Regular inspections should focus on identifying signs of wear, corrosion, deformation, or loosened attachment points. For example, corrosion may be more prevalent in steel or aluminum models exposed to moisture; here, protective coatings and prompt repairs are critical.

Implementing routine checks, such as the “TWA” (Visual, Touch, and Audible) method, can help operators quickly assess the condition of steps. Visual inspections for cracks or corrosion, tactile assessments for roughness or looseness, and auditory tests for unusual sounds during movement provide comprehensive evaluations.

When deterioration is detected—such as corrosion-induced thinning of steel or embrittlement of fiberglass—replacement or professional refurbishing should be prioritized to prevent failure under load.

Best practices for maintenance

- Clean steps regularly to remove debris and contaminants that may compromise surface grip

- Apply protective coatings or anti-slip tapes as necessary

- Secure attachment points tightly and re-tighten bolts periodically

- Replace worn or damaged steps immediately, adhering to manufacturer guidelines

Ergonomics and User Experience in Step Ladder Design

Beyond raw strength, ergonomic considerations in step ladder steps influence user safety and comfort. Ideally, steps should accommodate a broad range of footwear, with surface textures providing reliable grip. Additionally, step dimensions must support natural foot placement, reducing fatigue and enhancing stability.

Studies indicate that optimized tread width (approximately 4 inches) and depth (around 4.5 inches) foster confidence, especially during extended use. Incorporation of ergonomic handrails and stable side rails complements the overall safety ecosystem.

Impact of ergonomic design on occupational safety

Properly designed steps reduce slip-and-fall incidents significantly, which comprise over 30% of work-related falls. Notable ergonomic features include beveled edges to prevent tripping, anti-fatigue coatings to reduce discomfort, and clear visual cues for step boundaries. Tailoring designs for specific environments—such as slippery industrial floors or uneven terrain—further enhances safety, demonstrating the importance of contextual tailoring.

| Relevant Category | Key Data |

|---|---|

| Step Width | Optimal 4 inches for general use, wider for specialized applications |

| Surface Texture | Roughened or abrasive coatings achieving R13 slip resistance rating |

| Weight Support | Supports user weight plus tools, typically up to 300 pounds in high-end models |

Technological Innovations and Future Directions in Step Ladder Step Manufacturing

The realm of step ladder steps is continuously evolving with technological advancements such as nanomaterials, smart sensors, and automated inspection systems. Nanocoatings, for example, promise exceptional durability combined with superhydrophobic and anti-slip properties, prolonging the lifespan of steps in even the most demanding environments.

Smart sensors embedded within steps could provide real-time data on structural integrity or environmental conditions, alerting operators to impending failures before they manifest visibly. Additionally, the advent of 3D printing has enabled rapid prototyping and customization, catering to bespoke safety requirements or specialized applications.

Emerging trends shaping industry practice

Potential directions include self-healing materials, which autonomously repair cracks or corrosion, and connected safety devices that synchronize with facility management systems. The integration of these technologies could significantly elevate safety protocols and operational efficiency.

| Relevant Innovation | Description |

|---|---|

| Nanocoatings | Enhance durability, slip resistance, and environmental resistance |

| Embedded Sensors | Monitor structural health in real-time, predictive maintenance capabilities |

| 3D Printing | Enable rapid, customized manufacturing of complex step designs |

Conclusion: Integrating Expertise, Standards, and Innovation for Safe Use

Ensuring the safety and stability of step ladder steps involves a multifaceted approach—combining solid engineering principles, adherence to industry standards, diligent maintenance, ergonomic design, and embracing technological advancements. As workplace safety continues to be a priority globally, continuous improvements in materials and design practices foster safer environments for workers and DIY enthusiasts alike. The future of step ladder step technology points toward smarter, more durable, and customizable solutions that can adapt to diverse needs and hazards. By understanding the critical factors highlighted in this guide, users and manufacturers can collaboratively uphold safety standards, ultimately reducing accidents and promoting a culture of vigilant safety consciousness.

What materials are most commonly used for step ladder steps and why?

+The most prevalent materials are aluminum alloys, reinforced fiberglass, and steel. Aluminum, especially 6061-T6, is favored for its lightweight properties and corrosion resistance, enabling ease of handling and longevity. Reinforced fiberglass provides excellent electrical insulation and chemical resistance, primarily used in environments with electrical hazards. Steel, often galvanized or treated, offers exceptional strength but adds weight, making it suitable for heavy-duty industrial applications. Material choice hinges on factors including load requirements, environmental exposure, electrical safety, and cost considerations.

How often should step ladder steps be inspected for safety?

+Industry guidelines recommend conducting visual and tactile inspections prior to every use, especially in demanding environments. Formal comprehensive inspections should occur at least quarterly, with detailed assessments focusing on corrosion, cracks, deformation, and attachment integrity. In high-use settings, monthly inspections might be warranted. Consistent maintenance and prompt repairs or replacements when issues arise are vital for ensuring continued safety and compliance with standards.

What are key ergonomic considerations in step ladder step design?

+Ergonomics emphasizes designing steps that support natural foot placement, typically with a tread width around 4 inches and depth close to 4.5 inches. Surface textures should provide reliable grip, even when wet or greasy. Additionally, step edges should be beveled or rounded to prevent tripping, and the overall height should minimize strain during ascent and descent. Incorporating ergonomic features reduces fatigue and fall risk, especially during prolonged or repetitive tasks.

What innovations are shaping the future of step ladder steps?

+Emerging innovations include nanocoatings for increased durability and slip resistance, embedded sensors for real-time structural monitoring, and the use of 3D printing for customization. These advances promise enhancements in safety, lifespan, and adaptability. Furthermore, self-healing materials capable of repairing cracks automatically and connected safety systems that alert users to potential hazards are poised to transform the industry standards and operational practices in the coming years.