The stress strain curve is a fundamental concept in the field of materials science and engineering, providing a graphical representation of the relationship between stress and strain in a material under tension or compression. This curve is essential in understanding the mechanical behavior of materials, including their strength, stiffness, and ductility. The stress strain curve is typically obtained through a uniaxial tensile test, where a material specimen is subjected to a gradually increasing tensile force until failure. The resulting curve provides valuable information on the material's elastic and plastic behavior, allowing engineers to design and optimize structures and components for various applications.

Key Points

- The stress strain curve is a graphical representation of the relationship between stress and strain in a material.

- The curve is obtained through a uniaxial tensile test, providing information on the material's elastic and plastic behavior.

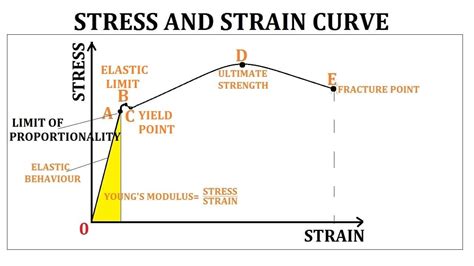

- The curve consists of several distinct regions, including the proportional limit, elastic limit, yield point, and ultimate tensile strength.

- Understanding the stress strain curve is crucial in designing and optimizing structures and components for various applications.

- The curve can be influenced by various factors, including material composition, microstructure, and testing conditions.

Components of the Stress Strain Curve

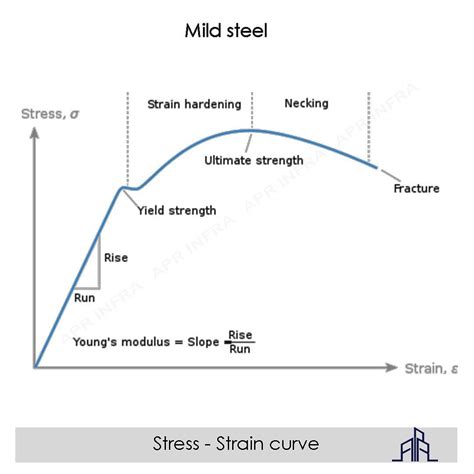

The stress strain curve can be divided into several distinct regions, each corresponding to a specific stage of the material’s deformation. The first region is the proportional limit, where the material exhibits a linear relationship between stress and strain, following Hooke’s law. This region is characterized by the material’s elastic behavior, where the strain is directly proportional to the applied stress. As the stress increases, the material reaches its elastic limit, beyond which the material begins to deform plastically. The yield point marks the transition from elastic to plastic deformation, where the material’s stress strain curve begins to deviate from linearity. The ultimate tensile strength represents the maximum stress that the material can withstand before failing.

Material Behavior Beyond the Yield Point

Beyond the yield point, the material enters the plastic deformation region, where the stress strain curve exhibits a non-linear behavior. In this region, the material undergoes significant deformation, resulting in a permanent change in shape. The material’s strain hardening behavior is characterized by an increase in strength with increasing strain, while strain softening behavior is marked by a decrease in strength with increasing strain. The necking phenomenon, where the material’s cross-sectional area decreases, can also occur in this region, leading to a localized reduction in strength.

| Material Property | Definition | Unit |

|---|---|---|

| Proportional Limit | Maximum stress at which the material exhibits a linear stress-strain relationship | MPa |

| Elastic Limit | Maximum stress at which the material returns to its original shape after unloading | MPa |

| Yield Point | Stress at which the material begins to deform plastically | MPa |

| Ultimate Tensile Strength | Maximum stress that the material can withstand before failing | MPa |

Factors Influencing the Stress Strain Curve

The stress strain curve can be influenced by various factors, including material composition, microstructure, and testing conditions. The material composition can significantly impact the curve, with different alloying elements affecting the material’s strength, ductility, and strain hardening behavior. The microstructure of the material, including grain size and orientation, can also influence the curve, with finer grain sizes typically resulting in higher strength and lower ductility. Testing conditions, such as temperature and strain rate, can also impact the curve, with higher temperatures and strain rates typically resulting in lower strength and higher ductility.

Importance of the Stress Strain Curve in Engineering Applications

Understanding the stress strain curve is crucial in designing and optimizing structures and components for various engineering applications. The curve provides valuable information on the material’s strength, stiffness, and ductility, allowing engineers to select the most suitable material for a specific application. The curve can also be used to predict the material’s behavior under different loading conditions, including tension, compression, and fatigue. By analyzing the stress strain curve, engineers can identify potential failure modes and design structures and components to mitigate these risks.

What is the significance of the stress strain curve in materials science?

+The stress strain curve is a fundamental concept in materials science, providing a graphical representation of the relationship between stress and strain in a material. It is essential in understanding the mechanical behavior of materials, including their strength, stiffness, and ductility.

How does the material composition influence the stress strain curve?

+The material composition can significantly impact the stress strain curve, with different alloying elements affecting the material’s strength, ductility, and strain hardening behavior. For example, adding chromium to steel can improve its strength and corrosion resistance.

What is the importance of the stress strain curve in engineering applications?

+Understanding the stress strain curve is crucial in designing and optimizing structures and components for various engineering applications. The curve provides valuable information on the material’s strength, stiffness, and ductility, allowing engineers to select the most suitable material for a specific application.