Stress testing using chemicals is a critical process in various industries, including manufacturing, construction, and pharmaceuticals. The primary goal of stress testing is to determine the durability and reliability of materials, products, or systems under extreme conditions. Chemical stress testing, in particular, involves exposing specimens to chemicals that can potentially degrade or damage them, thereby simulating real-world scenarios. This process helps manufacturers and researchers identify potential weaknesses, optimize product design, and ensure compliance with regulatory standards.

Chemical stress testing can be applied to a wide range of materials, including metals, polymers, ceramics, and composites. The choice of chemicals used for stress testing depends on the specific application and the material being tested. For example, in the automotive industry, chemicals such as saltwater, acid, and alkaline solutions are used to simulate the effects of corrosion on metal components. In the pharmaceutical industry, chemicals such as solvents, buffers, and preservatives are used to test the stability and compatibility of drug formulations.

Key Points

- Chemical stress testing is used to evaluate the durability and reliability of materials and products under extreme conditions.

- The process involves exposing specimens to chemicals that can potentially degrade or damage them.

- Chemical stress testing is applied to a wide range of materials, including metals, polymers, ceramics, and composites.

- The choice of chemicals used for stress testing depends on the specific application and the material being tested.

- Chemical stress testing helps manufacturers and researchers identify potential weaknesses, optimize product design, and ensure compliance with regulatory standards.

Types of Chemical Stress Testing

There are several types of chemical stress testing, each designed to simulate specific environmental conditions. These include:

Corrosion Testing

Corrosion testing involves exposing materials to chemicals that can cause corrosion, such as saltwater, acid, and alkaline solutions. This type of testing is commonly used in the automotive, aerospace, and construction industries to evaluate the durability of metal components.

Chemical Resistance Testing

Chemical resistance testing involves exposing materials to chemicals that can potentially degrade or damage them. This type of testing is commonly used in the pharmaceutical and food processing industries to evaluate the compatibility of materials with chemicals used in manufacturing processes.

Stability Testing

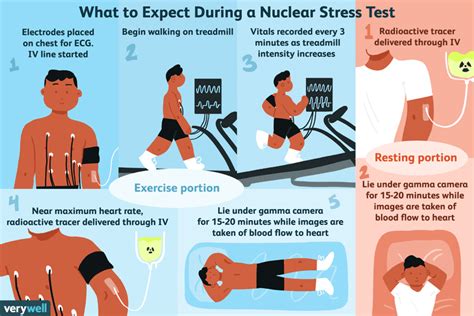

Stability testing involves exposing materials to chemicals that can affect their stability, such as light, heat, and moisture. This type of testing is commonly used in the pharmaceutical industry to evaluate the stability of drug formulations.

| Chemical Stress Testing Type | Description |

|---|---|

| Corrosion Testing | Evaluates the durability of materials in the presence of corrosive chemicals. |

| Chemical Resistance Testing | Evaluates the compatibility of materials with chemicals used in manufacturing processes. |

| Stability Testing | Evaluates the stability of materials in the presence of chemicals that can affect their stability. |

Applications of Chemical Stress Testing

Chemical stress testing has a wide range of applications in various industries, including:

Automotive Industry

In the automotive industry, chemical stress testing is used to evaluate the durability of metal components, such as engine blocks, cylinder heads, and exhaust systems. The process involves exposing specimens to chemicals that can cause corrosion, such as saltwater, acid, and alkaline solutions.

Pharmaceutical Industry

In the pharmaceutical industry, chemical stress testing is used to evaluate the stability and compatibility of drug formulations. The process involves exposing specimens to chemicals that can affect their stability, such as light, heat, and moisture.

Construction Industry

In the construction industry, chemical stress testing is used to evaluate the durability of building materials, such as concrete, steel, and wood. The process involves exposing specimens to chemicals that can cause corrosion, such as saltwater, acid, and alkaline solutions.

Chemical stress testing is a critical process in ensuring the durability and reliability of materials and products. By simulating real-world scenarios, manufacturers and researchers can identify potential weaknesses, optimize product design, and ensure compliance with regulatory standards. The applications of chemical stress testing are diverse and continue to grow as new industries and technologies emerge.

What is chemical stress testing?

+Chemical stress testing is a process used to evaluate the durability and reliability of materials and products under extreme conditions. It involves exposing specimens to chemicals that can potentially degrade or damage them, thereby simulating real-world scenarios.

What are the types of chemical stress testing?

+There are several types of chemical stress testing, including corrosion testing, chemical resistance testing, and stability testing. Each type of testing is designed to simulate specific environmental conditions.

What are the applications of chemical stress testing?

+Chemical stress testing has a wide range of applications in various industries, including the automotive, pharmaceutical, and construction industries. It is used to evaluate the durability and reliability of materials and products, identify potential weaknesses, and ensure compliance with regulatory standards.