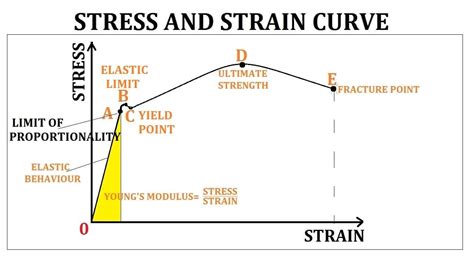

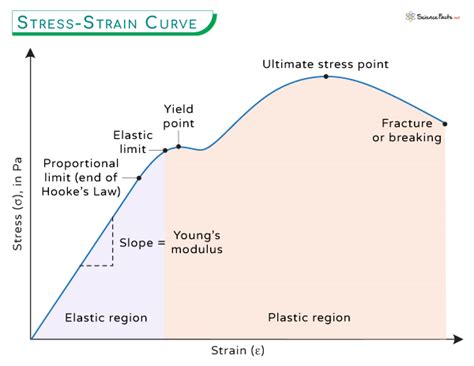

The stress-strain curve is a fundamental concept in the field of materials science and engineering, providing valuable insights into the mechanical behavior of various materials under different types of loading. It is a graphical representation of the relationship between the stress (force per unit area) applied to a material and the resulting strain (deformation per unit length). Understanding the stress-strain curve is crucial for engineers and researchers to design and develop materials with specific properties, predict material failure, and optimize structural performance.

Introduction to Stress-Strain Curve

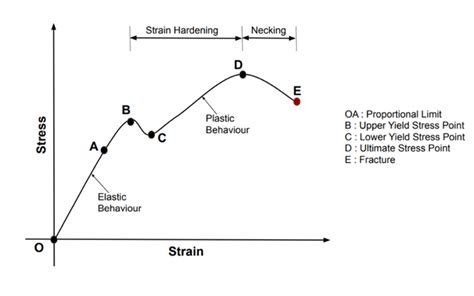

The stress-strain curve is typically obtained through uniaxial tensile testing, where a material specimen is subjected to a controlled amount of stress, and the resulting strain is measured. The curve is divided into several distinct regions, each representing a different stage of material behavior. The initial portion of the curve, known as the elastic region, is characterized by a linear relationship between stress and strain. In this region, the material behaves elastically, and the strain is directly proportional to the applied stress. The slope of this linear portion is representative of the material’s elastic modulus, also known as Young’s modulus.

Elastic Region and Yield Point

Beyond the elastic region, the stress-strain curve enters the plastic region, where the material begins to deform permanently. The point at which this transition occurs is known as the yield point or yield strength. At this point, the material starts to exhibit significant plastic deformation, and the stress-strain curve deviates from its initial linear behavior. The yield point is a critical parameter in material selection and design, as it marks the onset of permanent deformation and potential material failure.

| Material Property | Typical Value |

|---|---|

| Yield Strength (MPa) | 250-500 |

| Ultimate Tensile Strength (MPa) | 400-700 |

| Elastic Modulus (GPa) | 200-210 |

Plastic Region and Ultimate Tensile Strength

As the material continues to deform beyond the yield point, it enters the plastic region, where significant strain hardening occurs. The stress-strain curve in this region is characterized by a non-linear relationship, with the material exhibiting increasing resistance to deformation. The ultimate tensile strength, also known as the tensile strength, is the maximum stress that a material can withstand before failing. This point is typically marked by a peak in the stress-strain curve, followed by a decline in stress as the material begins to neck and eventually fail.

Necking and Ductility

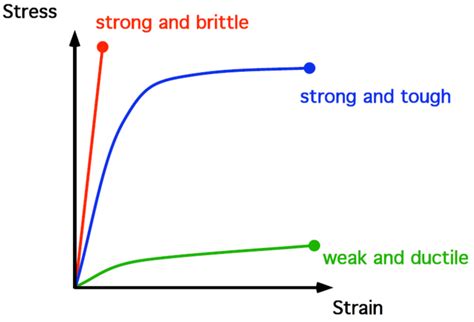

The final stage of the stress-strain curve is characterized by the onset of necking, where the material begins to localize deformation and reduce its cross-sectional area. This region is critical in determining the material’s ductility, which is a measure of its ability to deform without failing. Materials with high ductility, such as copper and aluminum, exhibit significant necking before failing, while brittle materials, such as glass and ceramics, tend to fail with little or no necking.

Key Points

- The stress-strain curve is a graphical representation of the relationship between stress and strain in a material.

- The curve is divided into distinct regions, including the elastic region, yield point, plastic region, and ultimate tensile strength.

- Understanding the stress-strain curve is crucial for material selection, design, and failure prediction.

- The yield point marks the onset of permanent deformation and potential material failure.

- Material ductility is determined by the extent of necking and deformation before failure.

Applications and Implications

The stress-strain curve has far-reaching implications in various fields of engineering, including aerospace, automotive, and civil engineering. By understanding the stress-strain behavior of materials, engineers can design structures that are optimized for performance, safety, and efficiency. Additionally, the stress-strain curve is essential in material selection, as it provides valuable insights into the material’s mechanical properties and potential failure modes.

Material Selection and Design

In material selection, the stress-strain curve is used to evaluate the suitability of a material for a specific application. For example, in the design of aircraft structures, materials with high strength-to-weight ratios and excellent ductility are preferred to ensure optimal performance and safety. Similarly, in the automotive industry, materials with high impact resistance and toughness are selected for crash-critical components.

What is the significance of the yield point in material selection?

+The yield point is a critical parameter in material selection, as it marks the onset of permanent deformation and potential material failure. Exceeding the yield point can lead to unforeseen material behavior and failure, making it essential to consider this value in design and selection.

How does the stress-strain curve relate to material ductility?

+The stress-strain curve is closely related to material ductility, as the extent of necking and deformation before failure determines the material's ductility. Materials with high ductility exhibit significant necking and deformation, while brittle materials tend to fail with little or no necking.

What are the implications of the stress-strain curve in structural design?

+The stress-strain curve has significant implications in structural design, as it provides valuable insights into the material's mechanical properties and potential failure modes. By understanding the stress-strain behavior of materials, engineers can design structures that are optimized for performance, safety, and efficiency.

Meta description suggestion: “Learn about the stress-strain curve, a fundamental concept in materials science and engineering, and its significance in material selection, design, and failure prediction.” (149 characters)