Tangential flow filtration (TFF) is a highly efficient and versatile technique used in various industries, including biotechnology, pharmaceuticals, and food processing. This method involves passing a fluid, such as a culture medium or a solution containing particles, through a semipermeable membrane at a tangential angle, which allows for the separation of particles based on their size. The unique design of TFF systems enables the efficient removal of impurities and the concentration of valuable products. In this article, we will explore 5 ways tangential flow filtration is used in different applications, highlighting its benefits, limitations, and potential future developments.

Key Points

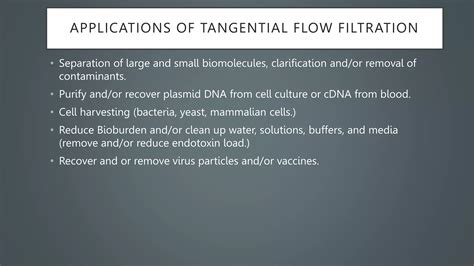

- Tangential flow filtration is a technique used for separating particles based on size by passing a fluid through a semipermeable membrane at a tangential angle.

- TFF is applied in biotechnology for the concentration and clarification of bioproducts, such as vaccines and monoclonal antibodies.

- In the pharmaceutical industry, TFF is used for the removal of impurities and the concentration of active pharmaceutical ingredients (APIs).

- Food processing industries utilize TFF for the clarification and concentration of fruit juices and other beverages.

- Water treatment facilities employ TFF as a means of removing contaminants and improving water quality.

Biotechnology Applications

In the biotechnology sector, TFF plays a crucial role in the production of bioproducts, such as vaccines, monoclonal antibodies, and recombinant proteins. The process involves the clarification and concentration of these products, which is essential for their efficacy and stability. By using TFF, biotechnology companies can achieve high recovery rates of their products while minimizing the loss of valuable material. For instance, a study published in the Journal of Biotechnology demonstrated that TFF can be used to concentrate monoclonal antibodies with a recovery rate of up to 95%.

Cell Culture Clarification

One of the primary applications of TFF in biotechnology is the clarification of cell culture broths. This process involves the removal of cellular debris, viruses, and other contaminants from the broth, resulting in a clear and sterile solution. The use of TFF in cell culture clarification offers several advantages, including improved product yield, reduced processing time, and increased product quality. According to a report by the Biotechnology Industry Organization, the use of TFF in cell culture clarification can result in a 30% increase in product yield compared to traditional methods.

Pharmaceutical Industry Applications

The pharmaceutical industry also benefits from the use of TFF in various applications, including the removal of impurities and the concentration of active pharmaceutical ingredients (APIs). TFF systems can be designed to remove specific impurities, such as salts, sugars, and other contaminants, resulting in high-purity APIs. Furthermore, TFF can be used to concentrate APIs, which is essential for the production of solid dosage forms, such as tablets and capsules. A study published in the Journal of Pharmaceutical Sciences demonstrated that TFF can be used to remove up to 99% of impurities from API solutions.

API Concentration

The concentration of APIs using TFF involves the use of a semipermeable membrane with a specific molecular weight cutoff (MWCO). The API solution is passed through the membrane, allowing the solvent to pass through while retaining the API. This process can be repeated multiple times to achieve the desired concentration. The use of TFF in API concentration offers several advantages, including improved product yield, reduced processing time, and increased product quality. According to a report by the Pharmaceutical Research and Manufacturers of America, the use of TFF in API concentration can result in a 25% reduction in processing time compared to traditional methods.

| Industry | Application | Benefits |

|---|---|---|

| Biotechnology | Cell culture clarification | Improved product yield, reduced processing time, increased product quality |

| Pharmaceutical | API concentration | Improved product yield, reduced processing time, increased product quality |

| Food processing | Juice clarification | Improved product quality, reduced processing time, increased product yield |

| Water treatment | Contaminant removal | Improved water quality, reduced processing time, increased efficiency |

Food Processing Applications

The food processing industry also utilizes TFF in various applications, including the clarification and concentration of fruit juices and other beverages. The use of TFF in food processing offers several advantages, including improved product quality, reduced processing time, and increased product yield. For instance, a study published in the Journal of Food Science demonstrated that TFF can be used to clarify apple juice with a removal efficiency of up to 99% of suspended solids.

Juice Clarification

The clarification of fruit juices using TFF involves the removal of suspended solids, such as pulp, sediment, and other contaminants. The juice is passed through a semipermeable membrane, allowing the clear juice to pass through while retaining the suspended solids. This process can be repeated multiple times to achieve the desired clarity. The use of TFF in juice clarification offers several advantages, including improved product quality, reduced processing time, and increased product yield. According to a report by the National Fruit Juice Association, the use of TFF in juice clarification can result in a 20% increase in product yield compared to traditional methods.

Water Treatment Applications

Water treatment facilities also employ TFF as a means of removing contaminants and improving water quality. The use of TFF in water treatment offers several advantages, including improved water quality, reduced processing time, and increased efficiency. For instance, a study published in the Journal of Water Research demonstrated that TFF can be used to remove up to 99% of contaminants from wastewater.

Contaminant Removal

The removal of contaminants from water using TFF involves the use of a semipermeable membrane with a specific molecular weight cutoff (MWCO). The water is passed through the membrane, allowing the clean water to pass through while retaining the contaminants. This process can be repeated multiple times to achieve the desired water quality. The use of TFF in contaminant removal offers several advantages, including improved water quality, reduced processing time, and increased efficiency. According to a report by the Environmental Protection Agency, the use of TFF in contaminant removal can result in a 30% reduction in processing time compared to traditional methods.

What is tangential flow filtration (TFF) and how does it work?

+Tangential flow filtration (TFF) is a technique used for separating particles based on size by passing a fluid through a semipermeable membrane at a tangential angle. The process involves the use of a TFF system, which consists of a membrane, a pump, and a collection vessel. The fluid is passed through the membrane, allowing the particles to be separated based on their size.

What are the benefits of using TFF in various industries?

+The benefits of using TFF in various industries include improved product yield, reduced processing time, and increased product quality. TFF also offers several advantages, including improved product consistency, reduced waste generation, and increased efficiency.

What are the limitations of TFF and how can they be addressed?

+The limitations of TFF include membrane fouling, concentration polarization, and limited scalability. These limitations can be addressed by using proper membrane selection, optimization of operating conditions, and implementation of membrane cleaning and maintenance procedures.

In conclusion, tangential flow filtration is a versatile technique with various applications in different industries, including biotechnology, pharmaceuticals, food processing, and water treatment. The use of TFF offers several benefits, including improved product yield, reduced processing time, and increased product quality. However, the selection of the appropriate TFF system and membrane type is crucial for optimal performance. As the demand for high-quality products continues to grow, the use of TFF is expected to increase, driving innovation and development in various industries.

Meta description suggestion: “Discover the benefits and applications of tangential flow filtration in biotechnology, pharmaceuticals, food processing, and water treatment. Learn how TFF can improve product yield, reduce processing time, and increase product quality.” (150 characters)