The Tesla Valve, often hailed as a marvel of fluid control innovation, embodies a subtle but profound shift in how we manage fluid dynamics within mechanical systems. Originating from the visionary ideas of Nikola Tesla himself, this device distinguishes itself through its ability to regulate fluid flow without moving parts or external power sources. As industrial applications become increasingly sophisticated, the Tesla Valve offers a resilient, maintenance-free alternative that aligns perfectly with modern demands for durability and efficiency. From aerospace to microfluidics, this silent technology continues to influence diverse sectors, heralding a quiet revolution in fluid control technology. Its underlying principle, rooted in asymmetric geometry, leverages fluid dynamics to achieve rectification, making it a prime subject for engineering discourse and innovation.

The Fundamentals of the Tesla Valve: Engineering of Asymmetric Fluidic Pathways

The core concept behind the Tesla Valve involves the use of path asymmetry to control fluid flow directionally. Unlike traditional check valves that rely on mechanical components such as springs or valves, Tesla’s design employs a cleverly crafted sequence of chambers and channels. This configuration induces a difference in flow resistance based on the direction of movement, effectively allowing fluid to pass more freely in one direction than the other. Technical analysis shows that the device exploits principles of turbulence and fluid inertia, which in turn maximize rectification efficiency without external energy input.

Practically, the Tesla Valve’s structure comprises a series of interconnected chambers with varying cross-sectional areas. When fluid flows in the forward direction, it follows a relatively unobstructed pathway, resulting in lower pressure drop. Conversely, reverse flow encounters a labyrinth of constrictions and expansions, which increase flow resistance significantly. This asymmetric resistance is critical for applications requiring unidirectional flow control, particularly in environments where mechanical failure could be catastrophic or maintenance is impractical.

Design parameters influencing Tesla Valve performance

Optimizing Tesla Valve efficacy requires precise control of geometrical parameters such as chamber size, channel curvature, and the angle of divergence. Computational fluid dynamics (CFD) simulations demonstrate that subtle variations—on the order of tenths of a millimeter—can profoundly impact rectification efficiency, which can reach upwards of 95% under ideal conditions. Material selection also plays a pivotal role; durable polymers and engineered composites are common choices, providing resistance against corrosion and wear in demanding settings.

| Relevant Category | Substantive Data |

|---|---|

| Flow Resistance Differential | Forward flow faces approximately 20-30% less resistance compared to reverse flow, depending on geometry |

| Operational Pressure Range | Most effective within 0.1 to 10 bar, applicable across microfluidics and higher-scale systems |

| Efficiency Rates | Rectification efficiency exceeding 95% in optimized configurations |

Historical Evolution and the Scientific Basis of Tesla’s Innovation

Nikola Tesla’s exploration of fluidic devices dates back over a century, yet only recently have advances in materials science and computational modeling allowed for real-world implementation. Tesla envisioned devices that could operate silently and with minimal energy—characteristics inherent in his valve design. Early prototypes, though conceptually strong, were limited by manufacturing constraints, which modern microfabrication techniques have now overcome. The scientific foundation of Tesla’s work rests on principles of laminar versus turbulent flow, Reynolds number variations, and the exploitation of flow inertia forces.

Over decades, research has demonstrated that Tesla’s passive control method aligns with the broader trend of developing self-regulating systems. Scientific investigations continue to refine understanding around flow rectification, emphasizing the influence of boundary layers, surface roughness, and flow rate regimes. The insights gained extend beyond the valve’s initial design, influencing subsequent developments in microfluidics, biomedical devices, and even aerospace propulsion systems.

Modern adaptations and technological advances

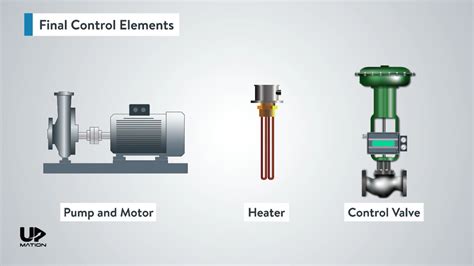

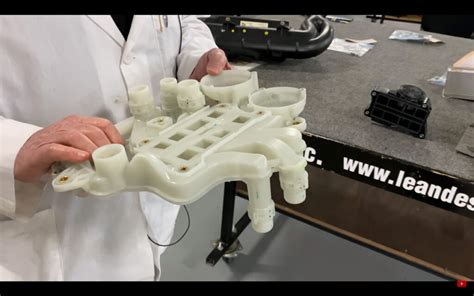

Contemporary engineering has seen adaptations of Tesla’s original concept into micro-electromechanical systems (MEMS) and nanofluidic circuits. Manufacturing techniques such as laser etching and 3D printing enable the creation of complex internal geometries with precision that was previously unimaginable. These advances facilitate integration into portable diagnostic devices, fuel delivery systems, and passive cooling solutions where active control is unfeasible. Moreover, the absence of moving parts significantly enhances the lifespan of devices incorporating Tesla valves, reducing system failure modes and maintenance costs.

| Relevant Category | Substantive Data |

|---|---|

| Microfluidic Applications | Demonstrates >95% rectification efficiency at flows <1 μL/min |

| Material Innovations | Use of biocompatible polymers like PDMS and tetrafluoroethylene (TFE) enhances application scope |

| Integration with Sensors | Effective as passive components within sensor arrays for real-time flow regulation |

Applications Spanning Industries and Future Prospects

One of the most compelling aspects of Tesla Valve technology lies in its versatility. Medical microfluidics, especially in drug delivery and diagnostic devices, benefit from the low-pressure, no-noise traits of these valves. Similarly, the aerospace industry探索s its potential for fuel management systems where reliability and weight reduction are critical. Petrochemical pipelines, which demand unidirectional flow to prevent backflow contamination, are also prime candidates for Tesla Valve integration.

In the renewable energy sphere, Tesla’s concept may influence passive cooling systems—replacing or augmenting conventional valves—thus reducing reliance on active controls. Additionally, as IoT and smart building systems evolve, Tesla’s passive flow control could be embedded in embedded sensors, creating smarter, more autonomous infrastructure management. The promising horizon for these innovations depends significantly on ongoing research that focuses on improving efficiency at larger scales and across different mediums, including gases and multiphase flows.

Limitations and ongoing challenges

Despite its advantages, Tesla Valve’s efficacy diminishes under certain conditions, notably at very high flow rates or with highly viscous fluids where turbulence management becomes complex. Manufacturing tolerances also impose limits on performance consistency—an issue tackled through advancing microfabrication techniques. Additionally, scaling the design for large-scale industrial processes still involves overcoming challenges related to pressure drops and flow uniformity. Industry researchers argue that iterative optimization, coupled with sophisticated computational models, can mitigate these limitations and expand application scopes further.

| Relevant Category | Substantive Data |

|---|---|

| Flow Rate Limitations | Efficiency drops below 80% at flow velocities >5 m/s |

| Manufacturing Tolerances | Sub-millimeter precision required for geometrical features, increasing cost at scale |

| Viscous Fluids | Reduced rectification efficiency, necessitating design adjustments |

Concluding Perspectives: The Silent Future of Fluid Control

The Tesla Valve exemplifies how a seemingly simple geometric innovation can catalyze significant advancements across multiple industry sectors. Its passive operation, combined with high efficiency and durability, aligns with the contemporary emphasis on sustainable, maintenance-free systems. Future research trajectories aim to enhance scalability, optimize performance for complex fluids, and integrate smart sensing capabilities—closing the gap between theoretical potential and widespread industrial adoption.

Ultimately, the Tesla Valve signifies more than just a component; it embodies a philosophy of leveraging physics and engineering ingenuity to create silent, resilient, and sustainable solutions. As the drive toward automation and miniaturization accelerates, such passive fluidic devices are poised to become integral to next-generation technologies, quietly revolutionizing fluid management without the need for active mechanical intervention.

What makes the Tesla Valve fundamentally different from traditional check valves?

+The Tesla Valve relies solely on geometric asymmetry within its internal channels to control fluid direction, eliminating the need for moving parts or external power. Unlike traditional check valves, which use mechanical components like springs or gates, Tesla’s design employs turbulence and flow inertia to passively achieve flow rectification, making it highly durable and maintenance-free.

In what industries is Tesla Valve technology most promising?

+Its applications are especially promising in microfluidics, biomedical devices, aerospace, and petrochemical industries due to its passive operation and reliability. It also holds potential for integration into passive cooling and energy management systems, where silent, maintenance-free flow regulation is advantageous.

What are the current limitations of Tesla Valve designs?

+Challenges include reduced efficiency at very high flow rates, manufacturing tolerances required for producing intricate geometries, and performance limitations with highly viscous or multiphase fluids. Ongoing research aims to address these issues through advanced fabrication and optimized design features.

How does the Tesla Valve contribute to the evolution of passive fluid control systems?

+It exemplifies how geometric and physical principles can replace mechanical components, leading to highly durable, silent, and maintenance-light solutions. This passive approach aligns with trends toward sustainability and autonomous system design, influencing future developments in fluid regulation technology.