Measuring tools are an essential part of various industries, including construction, engineering, and manufacturing. These tools enable professionals to accurately measure distances, angles, and other physical properties, ensuring that their work meets the required standards and specifications. With the advancement of technology, measuring tools have evolved to become more precise, efficient, and user-friendly. In this guide, we will explore the different types of measuring tools, their applications, and the importance of accuracy in measurement.

Key Points

- Understanding the different types of measuring tools and their applications

- The importance of accuracy in measurement and its impact on various industries

- Calibration and maintenance of measuring tools to ensure precision and reliability

- Emerging trends in measuring technology, including digital and laser-based tools

- Best practices for selecting and using measuring tools in various contexts

Types of Measuring Tools

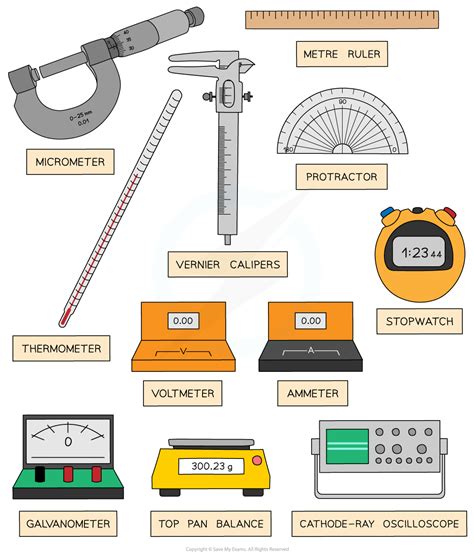

Measuring tools can be broadly categorized into two main types: traditional and modern. Traditional measuring tools include rulers, tape measures, and calipers, which are widely used for measuring distances and sizes. Modern measuring tools, on the other hand, include digital and laser-based instruments, such as digital calipers, laser distance meters, and coordinate measuring machines (CMMs). These tools offer higher precision and efficiency, making them ideal for complex measurements and applications.

Traditional Measuring Tools

Traditional measuring tools are simple, yet effective, and have been used for centuries. Rulers and tape measures are commonly used for measuring distances and sizes, while calipers are used for measuring the diameter and thickness of objects. These tools are relatively inexpensive and easy to use, making them accessible to a wide range of users. However, they may not offer the same level of precision as modern measuring tools, and their accuracy can be affected by human error.

| Traditional Measuring Tool | Application | Accuracy |

|---|---|---|

| Ruler | Measuring distances and sizes | ±1 mm |

| Tape Measure | Measuring distances and sizes | ±5 mm |

| Caliper | Measuring diameter and thickness | ±0.1 mm |

Modern Measuring Tools

Modern measuring tools have revolutionized the way we measure physical properties. Digital calipers, for example, offer high precision and accuracy, making them ideal for complex measurements. Laser distance meters, on the other hand, use laser technology to measure distances and sizes, offering high accuracy and efficiency. CMMs are used for measuring the geometry of objects, offering high precision and accuracy.

Digital Measuring Tools

Digital measuring tools have become increasingly popular in recent years due to their high precision and accuracy. Digital calipers, for example, can measure distances and sizes with an accuracy of ±0.01 mm, making them ideal for complex measurements. Laser distance meters, on the other hand, can measure distances and sizes with an accuracy of ±1 mm, making them ideal for construction and engineering applications.

Calibration and Maintenance of Measuring Tools

Calibration and maintenance of measuring tools are crucial to ensure their precision and reliability. Measuring tools should be calibrated regularly to ensure that they are accurate and reliable. Maintenance involves cleaning and storing the tools properly, as well as performing regular checks to ensure that they are functioning correctly.

Best Practices for Calibration and Maintenance

Best practices for calibration and maintenance of measuring tools include regular calibration, proper storage, and regular checks. Measuring tools should be calibrated at least once a year, or as recommended by the manufacturer. Proper storage involves keeping the tools in a dry, cool place, away from direct sunlight and moisture. Regular checks involve verifying that the tools are functioning correctly and accurately.

| Calibration and Maintenance Practice | Frequency | Importance |

|---|---|---|

| Calibration | At least once a year | High |

| Proper Storage | Always | High |

| Regular Checks | Regularly | Medium |

Emerging Trends in Measuring Technology

Emerging trends in measuring technology include the development of digital and laser-based tools. Digital measuring tools, such as digital calipers and laser distance meters, offer high precision and accuracy, making them ideal for complex measurements. Laser-based tools, such as laser scanners and laser trackers, offer high accuracy and efficiency, making them ideal for construction and engineering applications.

Advantages of Digital and Laser-Based Tools

Digital and laser-based tools offer several advantages over traditional measuring tools. They offer high precision and accuracy, making them ideal for complex measurements. They are also efficient and easy to use, making them ideal for construction and engineering applications. Additionally, they offer real-time data and analysis, making them ideal for applications that require rapid decision-making.

What is the most accurate type of measuring tool?

+The most accurate type of measuring tool is the digital caliper, which can measure distances and sizes with an accuracy of ±0.01 mm.

How often should measuring tools be calibrated?

+Measuring tools should be calibrated at least once a year, or as recommended by the manufacturer.

What is the advantage of using digital measuring tools?

+The advantage of using digital measuring tools is that they offer high precision and accuracy, making them ideal for complex measurements. They are also efficient and easy to use, making them ideal for construction and engineering applications.

In conclusion, measuring tools are an essential part of various industries, and their accuracy and precision are crucial to ensuring that work meets the required standards and specifications. By understanding the different types of measuring tools, their applications, and the importance of calibration and maintenance, professionals can select the right tool for the job and ensure that their work is accurate and reliable. As technology continues to evolve, we can expect to see even more advanced and precise measuring tools that will further improve the efficiency and accuracy of measurements.