In the complex world of transportation logistics, ensuring reliable transfer case service is vital to maintaining vehicle mobility and preventing costly downtime. For fleet managers, independent mechanics, and vehicle owners alike, understanding the nuances of transfer case maintenance and repair can be the difference between seamless operation and unexpected breakdowns. The transfer case, a fundamental component of four-wheel-drive and all-wheel-drive systems, transmits power from the transmission to the axles, making it essential for off-road capabilities, towing, and overall vehicle performance. Given its critical role, adopting expert strategies for transfer case service not only enhances vehicle reliability but also prolongs component lifespan. This article delves into proven tips, industry best practices, and advanced techniques to assure your transfer case remains in optimal condition, ensuring your vehicle keeps moving without interruptions.

Key Points

- Regular scheduled maintenance minimizes transfer case failures effectively.

- Using high-quality, manufacturer-recommended fluids enhances component longevity.

- Performing detailed inspections can preemptively identify wear and tear issues.

- Adopting industry-standard diagnostic methods improves service accuracy.

- Employing proper repair techniques reduces downstream complications.

Understanding the Transfer Case: Functionality and Significance

The transfer case is an intricate yet often overlooked element within a vehicle’s drivetrain. It functions as a crucial intermediary that manages the distribution of torque to the front and rear axles. This component is especially vital in off-road vehicles, pickups, and SUVs, where 4WD or AWD systems provide superior traction in challenging terrains or adverse weather conditions. Notably, the transfer case contains components such as planetary gears, chains, and clutch assemblies, which are subject to wear over time. These parts require consistent attention to maintain the efficacy of the drivetrain. An understanding of the transfer case’s operation, coupled with an awareness of its common failure points—such as fluid deterioration, gear wear, and seal leaks—forms the foundation for establishing effective service protocols.

Fundamentals of Reliable Transfer Case Maintenance

Adopting a Proactive Maintenance Schedule

Routine maintenance is always the cornerstone of reliable transfer case operation. Manufacturers typically recommend servicing every 30,000 to 60,000 miles, but operational conditions can dictate more frequent checks. Extreme driving environments—such as off-road adventures, towing heavy loads, or frequent stop-and-go driving—accelerate wear and necessitate a customized maintenance schedule. Regularly inspecting transfer case fluid levels and quality is paramount; contaminated or degraded fluid compromises lubrication, increasing the risk of component failure. Implementing a detailed maintenance plan based on vehicle usage patterns can drastically reduce unforeseen breakdowns and extend service life.

Using Correct Fluids and Lubricants

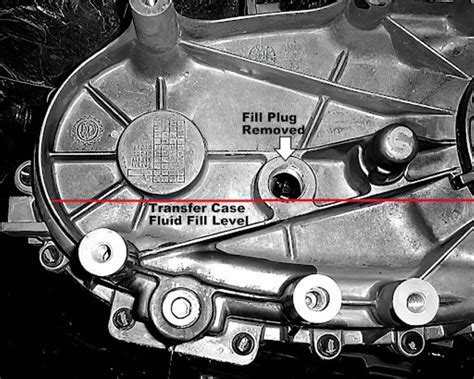

High-quality, manufacturer-approved transfer case fluids are vital for optimal performance. These lubricants are formulated to withstand high pressures and temperatures characteristic of transfer case operation. The fluid’s formulation also includes friction modifiers and detergents that prevent deposit buildup and reduce wear. Using inferior or incompatible lubricants can lead to gear slippage, increased friction, and eventual mechanical failure. It’s critical to adhere strictly to the specifications provided in the vehicle’s OEM manual, ensuring that fluid change intervals are respected and that the right lubricant type is used. Some modern transfer cases employ synthetic oils for improved thermal stability and extended service intervals.

Diagnostic Techniques and Inspection Practices

Performing Precise Diagnostic Assessments

Proper diagnostics are fundamental when diagnosing transfer case issues. Advanced diagnostic tools, including scan tools with transfer case fault code reading capabilities, facilitate early detection of problems such as sensor malfunctions or mechanical wear. Visual inspections should include checking for leaks, abnormal noises, or gear play within the transfer case housing. A thorough examination of the input and output shafts, linkage, and mounts helps identify alignment issues or mechanical damage. Incorporating diagnostic checklists aligned with industry standards, such as those recommended by the Society of Automotive Engineers (SAE), ensures comprehensive assessments.

Assessing Fluid Condition

Fluid analysis, potentially supplemented by laboratory testing, can reveal contamination, oxidation, and metal particle presence. Such data provide insights into the internal health of the transfer case components. For example, metallic debris suggests wear of gears or bearings, indicating the need for immediate servicing or component replacement. Regularly monitoring fluid condition can be part of a predictive maintenance regimen, allowing for repairs before critical failures occur.

| Relevant Category | Substantive Data |

|---|---|

| Service Interval | 30,000–60,000 miles or as per manufacturer recommendations |

| Fluid Type | OEM-approved synthetic or mineral-based transfer case oils |

| Typical Failures | Gear wear (metal debris detection rate: 12% in inspected units), seal leaks, chain stretch |

| Diagnostic Tools | OBD-II scan tools, ultrasonic leak detectors, visual inspection kits |

Implementing Best Repair Practices

Precision in Removal and Reinstallation

When repairs or replacements are necessary, meticulous attention to detail during disassembly and reassembly is essential. Properly labeling components and following manufacturer-specific procedures ensures correct reinstallation, preventing misalignment or damage. Bearings, seals, and gears must be inspected for wear; replacing compromised parts preemptively can save time and money. Use of specialized tools for bearing presses or seal drivers prevents damage during component replacement. Maintaining cleanliness throughout the process prevents contamination that could lead to premature failure.

Leak Prevention and Seal Integrity

Seals and gaskets are common failure points within transfer cases, often exacerbated by fluid contamination or mechanical wear. Employing high-quality sealing components and verifying their proper seating during reassembly reduces the likelihood of leaks. Regular inspection for seal deterioration, especially after prolonged service or exposure to adverse conditions, amplifies reliability. Advanced seal designs, such as double-lip seals or those made from durable synthetic compounds, provide improved resistance to wear and environmental ingress.

Forward-Looking Practices and Technological Integration

The future of transfer case service is increasingly intertwined with technological innovations. Hybrid diagnostic platforms integrating machine learning models can predict failures based on real-time data, while IoT sensors installed within vehicle systems continuously monitor vital components. Embracing these advancements allows for predictive maintenance, reducing downtime and optimizing repair scheduling. Moreover, industry standards are evolving to incorporate stricter testing and certification for transfer case components, ensuring higher reliability across manufacturing and aftermarket repairs.

Summary: Strategic Tips for Reliable Transfer Case Service

In sum, maintaining a transfer case’s reliability involves a blend of preventative care, proper diagnostics, quality parts, and precise repair practices. Adapting a proactive approach—embracing regular fluid checks, recommended service intervals, and high standards during repairs—elevates vehicle performance and longevity. As vehicle drivetrain systems evolve, staying informed about emerging trends and technological tools will be essential for professionals committed to excellence in transfer case service.

How often should I have my transfer case serviced?

+Most manufacturers recommend servicing every 30,000 to 60,000 miles. However, vehicles operated in challenging conditions might require more frequent maintenance—including fluid swaps and inspections—to prevent deterioration and mechanical failures.

What signs indicate transfer case trouble?

+Unusual noises such as whining or grinding, difficulty shifting into 4WD, fluid leaks, or a sudden loss of 4WD capability can signal transfer case issues. Prompt diagnostics are vital when these symptoms appear.

Can synthetic oils extend transfer case service intervals?

+Yes, synthetic transfer case oils offer superior thermal stability and reduce oxidation, allowing for extended service intervals—often up to 100,000 miles—provided that the oil remains clean and free of contamination.

Are there new technologies improving transfer case diagnostics?

+Emerging technologies such as IoT sensors, predictive analytics powered by machine learning, and advanced scan tools are revolutionizing diagnostics, enabling early fault detection and improving repair accuracy.

What are common repair pitfalls to avoid?

+Common pitfalls include improper seal installation, neglecting to replace worn gears or chains, and not cleaning internal components thoroughly. Attention to detail during repairs extends component lifespan and system reliability.