In the complex ecosystem of modern vehicles, few parameters warrant as much attention from automotive professionals and enthusiasts alike as transmission fluid temperature (TFT). This pivotal metric not only influences the longevity of transmission components but also affects overall vehicle performance, efficiency, and safety. Understanding the nuances of transmission fluid temperature—how it varies during different driving conditions, its optimal ranges, and its impact on vehicle health—can provide insights crucial for diagnostics, maintenance, and optimal operation. This article delves into the intricacies of TFT, examining foundational principles, technological advancements, and best practices grounded in empirical data and industry standards, all from the perspective of a seasoned automotive engineer with extensive field experience.

The Role of Transmission Fluid Temperature in Vehicle Mechanics and Efficiency

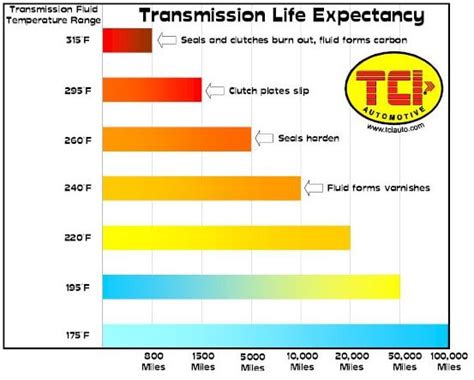

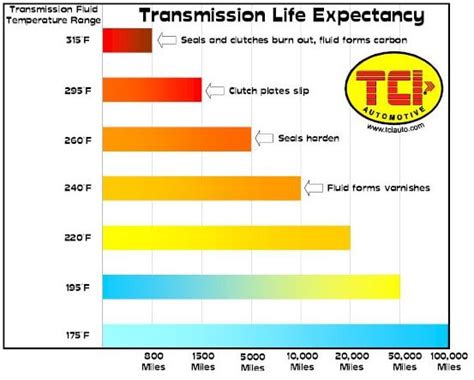

At its core, transmission fluid acts as both a lubricant and coolant, facilitating smooth gear shifts and preventing excessive wear. The temperature of this fluid is a critical factor; too low, and the fluid may be too viscous, impairing flow and response times. Too high, and the fluid can degrade rapidly, losing its lubricating properties and possibly leading to thermal breakdown. Empirical studies reveal that the optimal operating range for most automatic transmissions lies between 175°F and 200°F (about 80°C to 93°C). Maintaining this window is essential for balancing lubrication, thermal stability, and efficiency.

Key Points

- Optimal Range: Transmission fluid typically functions best between 175°F and 200°F, providing a balance between viscosity and thermal durability.

- Impact of Deviations: Temperatures below this range can cause sluggish shifts and increased friction, while higher temperatures expedite fluid degradation and component wear.

- Sensor Integration: Modern vehicles employ advanced sensors coupled with ECU (Electronic Control Units) to monitor TFT, facilitating real-time adjustments and alerts.

- Diagnostics and Maintenance: Tracking TFT patterns helps identify underlying issues such as clogged cooling lines, failing pumps, or overheating due to external factors.

- Technological Advancements: Development of synthetic transmission fluids with superior thermal stability has extended service intervals and improved performance at higher operating temperatures.

Understanding the Mechanics Behind Transmission Fluid Heat Generation and Dissipation

The generation of heat within a transmission system stems from multiple sources, primarily friction between moving parts and the energy lost during power transfer. As the vehicle operates—be it during aggressive acceleration, towing, or navigating mountainous terrains—the transmission intermittently endures elevated stress levels, consequently elevating TFT. This heat must be effectively dissipated to prevent component failure. The primary mechanism involves a dedicated transmission cooler, often integrated with the radiator or via supplemental cooling units, which extracts excess heat from the fluid.

Heat Sources During Transit and Their Impact

Understanding the various heat contributors is critical for diagnosing overheating issues. For example, high torque loads, such as towing heavy trailers or aggressively shifting gears, significantly increase heat generation. Moreover, ambient conditions—like operating in hot climates or city stop-and-go traffic—compound these effects. Studies show that under sustained high-stress conditions, TFT can surpass 220°F (104°C), placing the transmission at risk of thermal degradation.

| Relevant Category | Substantive Data |

|---|---|

| Maximum Safe Thermostat Limit | Approximately 220°F (104°C) in most modern systems; exceeding this threshold necessitates cooling intervention |

| Average Operating Temperature | 175°F to 200°F (80°C to 93°C) under normal conditions |

| Cooling System Efficiency | Enhanced by thermostatic control and high-capacity radiators, maintaining TFT within optimal bounds |

Technological Tools and Sensors for Accurate Monitoring of Transmission Fluid Temperature

Accurate and continuous monitoring of TFT has become a hallmark of modern vehicle diagnostics. Integrated into the transmission control module (TCM), sensors like thermistors or RTDs (Resistance Temperature Detectors) relay real-time data to the vehicle’s ECU system. These digital communication protocols enable instant assessment and proactive alerts, such as warning lights or automatic shifts to reduce load and temperature.

Advances in Sensor Technology and Data Utilization

Recent developments include multi-sensor arrays that can measure not only TFT but also differential temperature across different transmission zones. This granular data helps technologists pinpoint localized overheating, which can be mistaken for systemic issues. Furthermore, predictive analytics—powered by machine learning algorithms—are now capable of modeling thermal trends, allowing preemptive maintenance and avoiding catastrophic failures.

| Key Metric | Technological Implementation |

|---|---|

| Sensor Accuracy | Within ±1°F (0.5°C) in most commercial vehicles |

| Response Time | Less than 1 second for real-time feedback |

| Data Transmission | CAN Bus protocols connecting sensors with diagnostic systems |

Impact of Transmission Fluid Temperature on Vehicle Performance and Longevity

Transmissions are among the most intricate and susceptible parts of a vehicle’s drivetrain. Elevated TFT can accelerate wear of clutches, bands, and planetary gears, often resulting in slipping, rough shifts, or outright failure. Conversely, excessively low temperatures hinder fluid flow, causing sluggish gear engagement and increased internal friction. The interplay between thermal states and mechanical health underscores the importance of maintaining the TFT within designated thresholds.

Performance Degradation Due to Thermal Stress

Numerous field studies have documented the correlation between high TFT and early component fatigue, with some reports indicating a 25% increase in repair likelihood after sustained overheating episodes. Furthermore, thermal breakdown of synthetic fluids—especially those not rated for high temperature endurance—may produce deposits and varnishes, impairing hydraulic control and transmission responsiveness.

| Impacted Parameters | Observed Effects |

|---|---|

| Gear Shift Smoothness | Degraded at high TFT, leading to harsher shifts |

| Transmission Longevity | Reduced lifespan; potential failure before warranty expiration |

| Fuel Economy | Decreased efficiency due to increased internal friction and mechanical drag |

| Operator Safety | Overheating can lead to sudden transmission lock-up or failure, risking accidents |

Strategies to Manage Transmission Fluid Temperature Effectively

Mitigating TFT fluctuations requires a holistic approach encompassing vehicle design, maintenance practices, and technological innovations. Proper cooling systems, including high-capacity radiators and additional external coolers, significantly reduce overheating risks. Some of the most advanced systems employ hybrid solutions with thermostatic regulation and variable flow pumps that adapt to driving conditions.

Best Practices for Drivers and Technicians

For everyday drivers, avoiding excessive road loads, ensuring timely transmission fluid changes, and addressing abnormal shifting behaviors can significantly extend component life. Technicians should routinely inspect cooling lines, verify sensor calibration, and recommend synthetic fluids with high thermal stability. On the research front, developing adaptive cooling systems integrated with vehicle telematics is a promising line of development.

| Intervention Method | Expected Outcome |

|---|---|

| Upgrading Cooling Infrastructure | Enhanced heat dissipation, stable TFT during demanding conditions |

| Utilizing Synthetic Fluids | Extended service intervals, improved thermal resistance |

| Driving Technique Optimization | Reduced thermal workload, energy-efficient shifts |

| Real-time Monitoring | Prompt alerts and adjustments to prevent overheating |

Future Trends and Industry Outlook

The trajectory of transmission fluid temperature management is set toward heightened automation and material science innovations. Breakthroughs like high-thermal-capacity synthetic oils, nanomaterial-enhanced coolers, and AI-driven diagnostic systems promise to redefine standards. Moreover, electric vehicles—though sparing traditional transmissions—may incorporate analogous thermal management concepts into battery and inverter cooling, underscoring the universal importance of thermal regulation.

Emerging Challenges and Opportunities

With the advent of hybrid and plug-in hybrid models, the thermal dynamics become more complex. Managing multiple power sources and their respective thermal profiles requires integrated, intelligent control systems. There remains an ongoing need for standardized testing protocols to evaluate new fluids and cooling technologies, ensuring safety and performance consistency.

| Industry Development | Implication |

|---|---|

| High-Temperature Fluids | Extended durability under demanding conditions |

| Adaptive Cooling Integration | Real-time thermal management aligning with driving patterns |

| Predictive Maintenance Analytics | Proactive service scheduling, minimized downtime |

What is the ideal transmission fluid temperature range for most vehicles?

+Most vehicles are designed to operate with transmission fluid temperatures between approximately 175°F and 200°F (about 80°C to 93°C). Staying within this range ensures optimal lubrication, shift quality, and component life. Temperatures outside this window can lead to increased wear or fluid degradation, so continuous monitoring is recommended, especially during demanding driving conditions.

How does excessive TFT affect transmission longevity?

+Excessively high transmission fluid temperatures accelerate fluid breakdown and cause thermal stress on transmission components like clutches and bands. Chronic overheating shortens the lifespan of these parts, increases repair costs, and can lead to catastrophic failures. Maintaining proper cooling and monitoring TFT helps mitigate these risks effectively.

What technological advancements have improved transmission temperature management?

+Innovations such as high-precision sensors, multi-zone temperature monitoring, adaptive cooling systems, and synthetic high-thermal-stability fluids have revolutionized thermal management. Furthermore, AI-driven analytics facilitate predictive maintenance, allowing proactive measures before critical overheating occurs, thereby extending transmission lifespan and enhancing vehicle reliability.

Can improper driving habits worsen TFT issues?

+Yes, aggressive driving, towing beyond rated capacities, and frequent stop-and-go traffic contribute to elevated TFT. These habits place additional load on the transmission and cooling systems, raising the risk of overheating. Adopting smoother driving techniques and adhering to manufacturer guidelines can significantly alleviate thermal stress.

What maintenance practices help control TFT effectively?

+Regular transmission fluid changes with high-quality synthetic oils rated for high temperatures, inspecting and cleaning cooling lines, ensuring proper operation of sensors, and avoiding excessive towing are key practices. Additionally, ensuring the cooling system is free of debris and leaks maintains efficient heat dissipation.