Maintaining proper tire pressure is often underestimated in vehicle maintenance, yet it remains critical to ensuring safety, vehicle longevity, and optimal performance. When tyre pressure drops below manufacturer-recommended levels, the risk of tire damage, compromised handling, and increased wear escalates significantly. Low tyre pressure not only compromises grip and braking but also fosters conditions conducive to tire damage such as sidewall flexing, overheating, and tread separation. Experts in automotive safety and tire technology consistently emphasize that proactive management of tyre pressure offers a remarkably effective approach to preventing costly and dangerous tyre failures. This comprehensive guide explores practical tips grounded in scientific understanding and industry best practices to prevent tyre damage caused by low pressure, ultimately safeguarding drivers and prolonging the lifespan of tires.

Understanding the Impact of Low Tyre Pressure on Tire Integrity

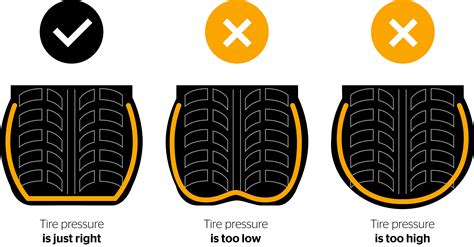

Before diving into preventative measures, it’s essential to understand why low tyre pressure presents such a threat to tire health. Tires are engineered with specific internal pressures to support vehicle weight evenly, optimize contact patch for traction, and facilitate heat dissipation. When pressure falls below recommended levels, several detrimental effects ensue:

- Increased Sidewall Flexing: Under-inflated tires exhibit exaggerated sidewall deformation, leading to premature cracking and potential blowouts.

- Overheating: The added flex increases internal heat, accelerating rubber degradation and softening structural components.

- Uneven Wear Patterns: Low pressure causes irregular tread wear, decreasing lifespan and increasing susceptibility to punctures or cuts.

- Reduced Handling and Safety: Compromised grip and increased braking distances elevate accident risk.

Given these outcomes, vigilant pressure management becomes an essential element of vehicle maintenance for both safety-critical situations and routine operational efficiency.

Scientific and Industry Perspectives on Tire Pressure Optimization

The National Highway Traffic Safety Administration (NHTSA) and automotive industry standards consistently recommend monitoring tyre pressure at least once a month. Data indicates that approximately 26% of vehicles on U.S. roads have at least one under-inflated tire by 25% or more, highlighting a widespread oversight. Studies reveal that maintaining proper pressure—typically within 1-2 psi of the manufacturer’s specifications—not only reduces rolling resistance and fuel consumption but also significantly extends tire life. Experts in tyre engineering, such as those holding Certified Automotive Tire Specialist credentials, support the use of advanced monitoring technologies to complement manual checks. Meanwhile, recent innovations like smart TPMS (Tire Pressure Monitoring Systems) have demonstrated up to 75% more timely alerts for pressure drops, providing an industry-driven shift toward preventative maintenance.

Practical Tips to Prevent Tire Damage Caused by Low Pressure

Consistent Monitoring and Maintenance

Perhaps the most straightforward yet effective tip involves establishing a routine. Regularly check tire pressure using a calibrated digital or analog gauge—preferably once a month and before long trips. The process should include:

- Ensuring the tire is cold—preferably before driving or after at least 3 hours of vehicle shutdown to avoid heat-induced pressure fluctuations.

- Comparing readings with the vehicle’s specified psi levels, available on the tire placard or owner’s manual.

- Refilling or letting out air to reach optimal pressure, followed by rechecking for precision.

Automakers increasingly advocate integrating digital TPMS sensors, which offer continual real-time data, minimizing human error.

Utilize Advanced Technologies for Continuous Monitoring

Incorporating smart TPMS devices enables drivers to receive instant alerts if pressure drops below safe thresholds. According to recent industry reports, these systems can reduce roadside tire failures by up to 60%, especially in commercial or fleet vehicles prone to pressure variations due to temperature or loading conditions. Selecting high-quality sensors that are compatible with OEM systems and conducting periodic calibration ensures consistent accuracy. Some models incorporate Bluetooth connectivity, allowing data to be transmitted directly to smartphones or vehicle dashboards, fostering proactive interventions.

Adopt Proper Inflation Procedures and Tools

Proper inflation tools and techniques are often overlooked. Use well-maintained pressure gauges rather than relying solely on gas station air pumps, which frequently provide inaccurate readings due to poor calibration or mechanical issues. When inflating, follow these steps:

- Check the recommended psi specific to each tire; avoid using a generic pressure value if the vehicle has load-dependent recommendations.

- Insist on slow, steady filling to prevent over-pressurization, yet ensure that the desired level is achieved—rapid filling can cause temperature spikes and inaccuracies.

- After inflation, re-measure to confirm the pressure is within safe limits.

Prevent Temperature-Related Pressure Variations

Temperature fluctuations significantly influence tyre pressure—every 10°C temperature change can alter tire pressure by approximately 1 psi. To mitigate this, plan tire checks during consistent ambient conditions, especially before and after exposure to extreme weather. Insulating tires from prolonged sunlight or cold environments; for instance, parking in shaded or garage areas; can stabilize pressure levels. Additionally, understanding the heat buildup during driving helps in avoiding damage—overheated tires are at higher risk of blowout or tread separation.

Addressing Additional Factors Contributing to Tire Damage

While low tyre pressure is a primary concern, other interrelated factors can exacerbate the risk of damage:

- Overloading: Heavier loads increase tire stress, especially when combined with under-inflation.

- Driving on Rough Surfaces: Potholes and debris can cause immediate punctures or weaken the sidewalls, particularly if tire pressure is insufficient to absorb shocks.

- Improper Tire Repairs: Substandard repairs or neglecting damage promptly often result in progressive failure under pressure stress.

Managing these variables involves maintaining overall vehicle health, ensuring proper loading, and being attentive to tire condition and repair quality.

Limitations and Challenges in Maintaining Optimal Tire Pressure

Despite technological advances, several hurdles exist in enforcing perfect pressure management. Human error during manual checks, delays in addressing PSI drops, and sensor malfunctions can undermine preventive efforts. Additionally, environmental factors like seasonal temperature swings require ongoing vigilance. Industry experts suggest integrating multiple strategies—combining regular manual checks with advanced sensors—as the most resilient approach. Nonetheless, awareness and education remain vital for consumers and operators alike, empowering informed decisions that reduce the chance of tire damage.

Future Trends in Tire Pressure Management

The evolution of smart tyre technologies points toward increasingly automated and predictive systems. Machine learning algorithms can now analyze auxiliary inputs such as vehicle load, ambient temperature, and driving patterns to forecast potential pressure declines before they occur. Moreover, advancements in tire materials—namely, self-healing rubber compounds—promise to mitigate damage in the early stages of pressure loss. Industry forecasts project that by 2030, nearly 90% of vehicles will incorporate integrated tyre health monitoring systems, drastically reducing tire failures attributable to low pressure.

Key Points

- Regular pressure checks are essential: Capacity for early detection prevents damage and safety risks.

- Leverage advanced sensor technology: Smart TPMS systems offer continuous, real-time pressure monitoring, vastly improving preventive maintenance.

- Account for environmental influences: Weather and temperature swings impact tyre pressure, necessitating seasonally sensitive practices.

- Address vehicle load and road conditions: Overloading and rough terrain amplify risks compounded by low tyre pressure.

- Stay informed about future innovations: Self-healing tires and predictive analytics promise a safer, more resilient tyre infrastructure.

FAQ Section

How often should I check my tire pressure?

+It’s advisable to check tire pressure at least once a month and before long trips, especially during seasonal changes when temperature fluctuations are more pronounced. Ensuring tires are cold—after the vehicle has been parked for over three hours—provides the most accurate readings.

Can I rely solely on a tire pressure monitoring system (TPMS) to prevent damage?

+While TPMS significantly enhances safety by providing real-time alerts, it’s not a substitute for manual checks. Sensor malfunctions or inaccuracies can occur, making regular visual inspections and manual pressure measurements a necessary complement.

What are the best practices for inflating tires properly?

+Use a high-quality, calibrated gauge for precision. Inflate tires when cold, following the manufacturer’s recommended PSI detailed on the vehicle’s placard or manual, and recheck after filling. Avoid rapid inflation to minimize temperature spikes and inaccuracies.

How do environmental factors affect tyre pressure?

+Temperature fluctuations directly impact air volume within the tire—around 1 psi change for every 10°C increase or decrease. Consistent ambient conditions help maintain stable pressure, and parking in shaded areas may reduce seasonal variance.

What advances are expected in future tire pressure management?

+Emerging technologies include integrated smart sensors with predictive analytics, self-healing materials, and AI-driven maintenance recommendations. By 2030, such innovations are anticipated to vastly reduce low-pressure-related failures and extend tire lifecycle.