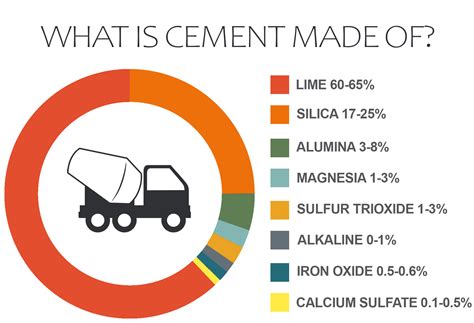

Cement is a fundamental component in the construction industry, serving as a binding agent that holds together the various elements of a structure, such as aggregate and water, to form concrete. The composition of cement is crucial in determining its properties and performance. Cement is typically made from a mixture of limestone, clay, sand, and other minerals, which are combined in specific proportions and then ground into a fine powder.

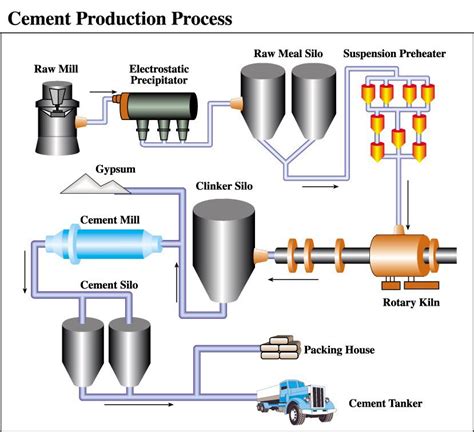

The primary components of cement include limestone (calcium carbonate, CaCO3), clay (silicates, SiO2), and sand (silicon dioxide, SiO2). These raw materials are abundant and can be sourced from quarries, mines, or other extraction sites. The manufacturing process involves several stages, including mining, crushing, grinding, and mixing, followed by calcination in a kiln at high temperatures, typically around 1450°C. This process, known as the calcination reaction, transforms the raw materials into a clinker, which is then cooled, ground into a fine powder, and mixed with gypsum (calcium sulfate, CaSO4·2H2O) to produce the final cement product.

Key Points

- Cement is a binding agent that holds together aggregate and water to form concrete.

- The primary components of cement include limestone, clay, and sand.

- The manufacturing process involves mining, crushing, grinding, mixing, calcination, and grinding again.

- Cement is used in various construction applications, including buildings, bridges, and infrastructure projects.

- The properties of cement, such as its strength and durability, are determined by its composition and manufacturing process.

The Chemistry of Cement

The chemistry of cement is complex and involves the reaction of the raw materials at high temperatures to form a series of compounds, including tricalcium silicate (C3S), dicalcium silicate (C2S), tricalcium aluminate (C3A), and tetracalcium aluminoferrite (C4AF). These compounds contribute to the strength, durability, and setting time of the cement. The hydration reaction, which occurs when cement comes into contact with water, is critical in the formation of the hardened cement paste that binds the aggregate together.

Cement Types and Applications

There are several types of cement, each with its own unique properties and applications. Ordinary Portland cement (OPC) is the most common type and is suitable for general construction purposes. Other types of cement include blended cements, such as Portland pozzolana cement (PPC) and Portland slag cement (PSC), which offer improved durability and sustainability. Specialized cements, such as sulfate-resistant cement and white cement, are designed for specific applications and environments.

| Cement Type | Properties | Applications |

|---|---|---|

| Ordinary Portland Cement (OPC) | General-purpose cement with good strength and durability | Building construction, infrastructure projects |

| Portland Pozzolana Cement (PPC) | Improved durability and resistance to chemical attack | Construction in aggressive environments, such as coastal areas |

| Portland Slag Cement (PSC) | Enhanced sustainability and reduced heat of hydration | Mass concrete structures, such as dams and foundations |

Cement Manufacturing Process

The cement manufacturing process is complex and involves several stages, from raw material extraction to final product packaging. The process can be broadly divided into two main categories: wet process and dry process. The wet process involves the use of water to grind the raw materials, while the dry process uses a dry grinding system. The choice of process depends on the availability of raw materials, energy costs, and environmental considerations.

Environmental Impact of Cement Production

Cement production is a significant contributor to greenhouse gas emissions, primarily due to the calcination reaction, which releases carbon dioxide (CO2) as a byproduct. The cement industry is also a major consumer of energy and natural resources. Efforts to reduce the environmental impact of cement production include the use of alternative fuels, waste reduction, and the development of more sustainable cement types, such as blended cements and supplementary cementitious materials (SCMs).

What is the primary component of cement?

+The primary component of cement is limestone, which is a source of calcium carbonate (CaCO3).

What is the purpose of the calcination reaction in cement production?

+The calcination reaction transforms the raw materials into a clinker, which is then ground into a fine powder to produce cement.

What are the main types of cement?

+The main types of cement include Ordinary Portland Cement (OPC), Portland Pozzolana Cement (PPC), and Portland Slag Cement (PSC), among others.

In conclusion, cement is a complex material with a rich chemistry and a wide range of applications. Understanding the composition, properties, and manufacturing process of cement is essential for selecting the appropriate type and grade for specific construction projects. As the construction industry continues to evolve, the development of more sustainable and environmentally friendly cement types will play a critical role in reducing the environmental impact of cement production.