Owning a 2006 Chevy Express means embracing a vehicle known for its durability and versatility, often serving as a workhorse for small businesses, family transport, or custom conversions. However, like any aging vehicle, its longevity greatly depends on meticulous maintenance and timely interventions. With over a decade and a half on the road, this model benefits from a systematic approach to upkeep grounded in both practical experience and technical understanding. For fleet managers, DIY enthusiasts, or owners seeking to optimize operational lifespan, understanding comprehensive maintenance strategies is paramount. This article delves into expert-recommended, data-supported maintenance practices tailored to the 2006 Chevy Express, emphasizing reliability, cost-efficiency, and safety—critical factors for any responsible vehicle owner.

Key Points

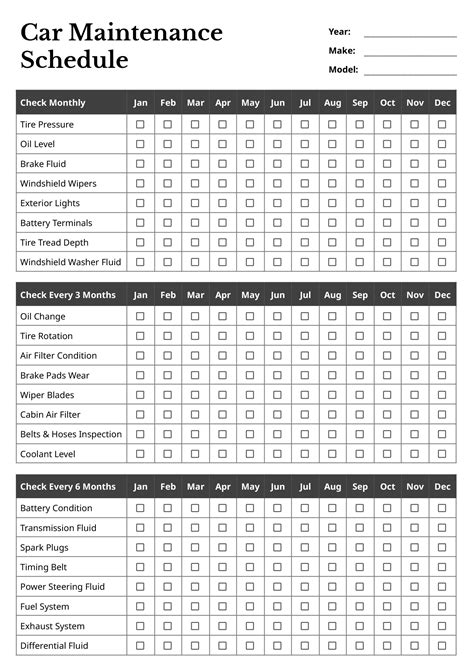

- Routine inspection schedules prevent unexpected breakdowns, extending vehicle lifespan significantly.

- Timely replacement of wear-and-tear components like brakes, belts, and fluids maintains optimal performance.

- Using manufacturer-recommended parts and fluids ensures compatibility, efficiency, and durability.

- Understanding specific model nuances, such as engine type and customization, informs precise maintenance needs.

- Adopting a proactive maintenance mindset reduces long-term costs and downtime, maximizing ROI for commercial users.

Introduction: Foundations of Reliable Maintenance for Your 2006 Chevy Express

The 2006 Chevy Express, with its robust V8 and I6 engine options, has reliably served myriad roles from cargo hauler to passenger van. As the vehicle ages, attention to nuanced maintenance becomes essential—particularly because its design, although sturdy, features aging technology and components that demand vigilant care. Experts in automotive longevity emphasize that proactive maintenance—performed with precision and adherence to manufacturer specifications—translates not only into extended vehicle life but also into increased safety and operational efficiency. For owners and fleet operators, understanding the specific needs of this model line, combined with a disciplined upkeep regimen, bridges the gap between mechanical longevity and cost-effective operation. In the paragraphs that follow, the focus shifts from foundational checks to detailed, expert-level insights designed to optimize your Chevy Express’s reliability.

Essential Maintenance Components for Longevity and Safety

Ensuring a dependable future for your 2006 Chevy Express involves a comprehensive understanding of its core maintenance areas. These span routine inspections, fluid management, wear part replacements, and system-specific calibrations. Given the age of the vehicle, prioritizing preventative care is vital—reducing the likelihood of costly repairs and unexpected failures. The key to achieving this is a disciplined, evidence-based maintenance schedule, aligned with industry standards such as those recommended by General Motors, and a thorough awareness of vehicle-specific identifiers like engine type, usage conditions, and modifications.

Fluid Management: Bloodline of Mechanical Reliability

Fluid maintenance remains the cornerstone of engine health in any vehicle, especially in the context of the 2006 Chevy Express, which has endured through many miles of service. Regular checking and changing of engine oil, transmission fluid, coolant, and brake fluid prevent corrosion, reduce wear, and mitigate overheating risks. For instance, the engine oil—often overlooked—should be replaced every 3,000 to 5,000 miles with high-quality synthetic or semi-synthetic formulations. Coolant flushes every 2 years maintain thermal efficiency and prevent corrosion in the radiator and engine block. Additionally, brake fluid should be replaced at least every two years to prevent moisture buildup and brake fade, critical in ensuring safe stopping power.

| Relevant Category | Substantive Data |

|---|---|

| Engine Oil Change Interval | 3,000-5,000 miles or annual, with synthetic oils extending to 7,500 miles based on driving conditions |

| Coolant Replacement | Every 2 years, or based on coolant additive package lifespan (as specified by Dex-Cool standards) |

| Brake Fluid Change | Every 24 months, with attention to moisture content and fluid color indicating system health |

Critical Wear Parts: Replacement Strategies to Prevent Failures

Wear parts are the Achilles’ heel of aging vehicles, yet with informed planning, their replacement can be optimized to prevent calamitous failures. Key components—including brakes, belts, hoses, and suspension parts—must be monitored with a keen eye. For example, the brake pads typically need replacement every 30,000 to 70,000 miles, depending on driving habits and load conditions. Worn belts, especially serpentine and timing belts, if neglected, can lead to engine overheating or catastrophic failure, emphasizing the importance of routine inspection at every oil change. Rubber hoses, susceptible to dry rot and cracking, should be replaced every 4-6 years, or immediately upon signs of deterioration.

Monitoring Tire and Suspension Integrity

Among various safety-critical systems, tires and suspension components warrant particular attention. Tire tread depth should be checked bi-monthly; when tread falls below 2⁄32 inch, replacement is advisable. Proper tire inflation, aligned with manufacturer specs—typically around 35 psi for the Express—optimizes fuel economy and safety. Suspension parts such as shock absorbers and bushings also degrade over time, impacting ride quality and handling. Visual inspection for leaks, cracks, or excessive wear allows timely replacement, preserving stability and safety.

| Relevant Category | Substantive Data |

|---|---|

| Brake Pad Replacement | 30,000 to 70,000 miles depending on operating conditions |

| Serpentine Belt Replacement | Between 60,000 and 100,000 miles or every 5-7 years |

| Tire Tread & Inflation | Replace once tread depth <2/32 inch; maintain 35 psi for best results |

Electrical System Maintenance: Ensuring Consistent Performance

The electrical system in the 2006 Chevy Express encompasses batteries, alternators, starter motors, and wiring harnesses. As these components age, issues such as slow cranking, dimming lights, or battery failures become more prevalent. Battery replacements are typically warranted every 3-5 years, with testing every 6-12 months as part of routine checkups. Alternator health can be gauged by voltage output, ideally between 13.8 and 14.8 volts when engine is running. Wiring insulation deterioration also warrants inspection, particularly in models with extensive modifications or aftermarket accessories. Precise electrical diagnostics ensure the prevention of unforeseen breakdowns and maintain consistent vehicle performance.

Routine Battery and Alternator Checks

Using a multimeter, owners can verify whether the battery voltage remains within the specified range. Besides, load testing provides a more accurate assessment of battery health. Fleet operators should perform these checks at least semi-annually, with more frequent evaluations in high-temperature climates where battery lifespan shortens. Ensuring proper connection terminals and corrosion-free contact points also affords longer component life and fewer electrical anomalies.

| Relevant Category | Substantive Data |

|---|---|

| Battery Lifespan | 3-5 years; replace when capacity drops below 80% |

| Alternator Output | 13.8-14.8 volts; checked during routine oil changes or similar maintenance |

| Wiring Inspection | Annually, especially in areas exposed to moisture or vibration |

Engine and Transmission Performance Optimization

The engine and transmission are the heart of your Chevy Express’s operational capability. For the 2006 models, whether equipped with a Vortec 5300 V8 or an inline-six, maintaining peak performance involves precise tuning and regular component inspection. Spark plugs, for example, should be replaced every 100,000 miles or sooner if signs of misfire or poor fuel economy emerge. Air filters, critical for combustion efficiency, need replacement every 12,000 to 15,000 miles or more frequently under dusty conditions. Additionally, maintaining the transmission fluid—typically every 30,000 to 60,000 miles—preserves smooth shifting and mitigates overheating risks.

Diagnostic Monitoring and Adaptive Maintenance

Modern diagnostic tools enable real-time monitoring of engine parameters, offering insights into sensor health and system efficiency. For older models like the 2006 Chevy Express, using OBD-II scanners can reveal stored error codes, potentially indicating issues with oxygen sensors, catalytic converters, or emissions systems. Addressing these proactively prevents more severe damage. Engine tuning, including recalibration of fuel maps and idle settings, ensures fuel economy and emissions standards are maintained. Working with seasoned mechanics familiar with GM’s engineering nuances is advisable for complex diagnostics and repairs.

| Relevant Category | Substantive Data |

|---|---|

| Spark Plug Replacement | Every 100,000 miles or when misfire occurs |

| Air Filter Change | 12,000-15,000 miles, more often in dusty environments |

| Transmission Fluid Service | Every 30,000-60,000 miles, or based on transmission performance |

Preservation Strategies for Aging Vehicles

As your 2006 Chevy Express accrues more miles, preventive maintenance shifts from routine checks to preservation strategies. To maximize longevity, owners should consider protective measures such as rustproofing, especially in regions with harsh winters. Regular lubrication of suspension and chassis components reduces wear from vibration and vibration-related fatigue. Some owners also opt for professional underbody inspections annually to detect early corrosion or structural deterioration. Additionally, keeping detailed maintenance logs aids in planning future repairs and demonstrates vehicle care—beneficial for resale or fleet management.

Innovative Upkeep: Technologies and Modern Practices

Emerging technological advances—like remote diagnostics via aftermarket telematics—enable fleet owners to monitor vehicle health continuously. For individual owners, investing in a comprehensive maintenance app simplifies scheduling, tracking service histories, and alerting for upcoming tasks. Some market solutions incorporate predictive analytics, forecast component failures, and suggest optimal maintenance windows, enhancing the predictive maintenance approach once reserved for high-end fleet management. Integration of these modern tools with traditional practices results in a seamlessly maintained vehicle that can reliably serve for many more years.

| Relevant Category | Substantive Data |

|---|---|

| Rustproofing | Annual applications in vulnerable regions extend body integrity, especially in salted environments |

| Underbody Inspection | Annually or biannually, looking for early signs of corrosion or structural fatigue |

| Telematics & Diagnostics | Real-time data access allows predictive maintenance and efficient scheduling |

Final Thoughts: Building a Customized Maintenance Plan

Every 2006 Chevy Express is unique, shaped by its usage, environment, and maintenance history. Creating a personalized, data-driven maintenance schedule—aligned with detailed inspection records—maximizes reliability while controlling costs. Consulting with certified mechanics familiar with older GM models ensures nuanced understanding and targeted repairs. Combining these expert insights with a disciplined upkeep routine transforms a well-worn workhorse into a dependable partner for years to come. Remember, investing in preventive care today reduces the risk of costly repairs tomorrow, ensuring your vehicle remains a trusted asset rather than a liability.

What are the top signs that my Chevy Express needs urgent maintenance?

+Indicators include persistent warning lights, unusual noises, poor acceleration, braking issues, or fluid leaks. When these signs appear, immediate inspection by a qualified mechanic is recommended to prevent further damage.

How often should I replace the timing belt on my 2006 Chevy Express?

+Generally, timing belts are not standard on all Express models, especially if equipped with timing chains. If your specific engine configuration includes a timing belt, replacement is advisable every 60,000 to 100,000 miles or as per the vehicle’s service manual.

Are aftermarket parts a viable option for maintenance on my Chevy Express?

+When sourced from reputable manufacturers and matched to OEM standards, aftermarket parts can provide cost-effective, reliable alternatives. However, verifying compatibility and warranty terms is essential to avoid compromising vehicle integrity.

What are the benefits of routine professional inspections versus DIY maintenance?

+Professional inspections offer expert diagnosis, access to specialized tools, and adherence to safety standards, catching issues that might elude DIY checks. While some routine maintenance—like oil changes—can be performed independently, complex diagnostics and system repairs benefit from professional expertise.