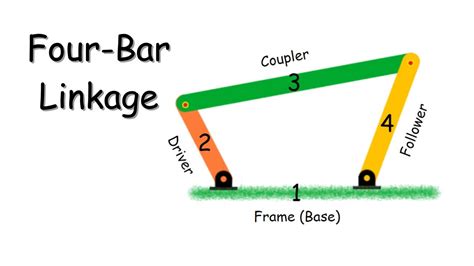

The 4 bar linkage is a fundamental mechanism in mechanical engineering, widely used in various applications, including robotics, automation, and mechanical systems. Its simplicity and versatility make it an essential component in many designs. To effectively utilize a 4 bar linkage, it's crucial to understand its dynamics, advantages, and limitations. In this article, we will delve into the world of 4 bar linkages, exploring their characteristics, design considerations, and practical applications.

Understanding the 4 Bar Linkage

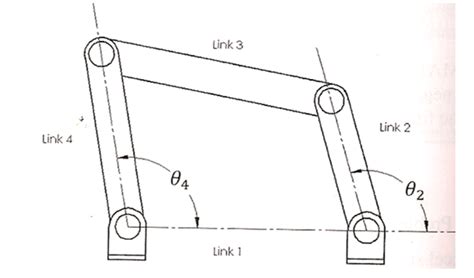

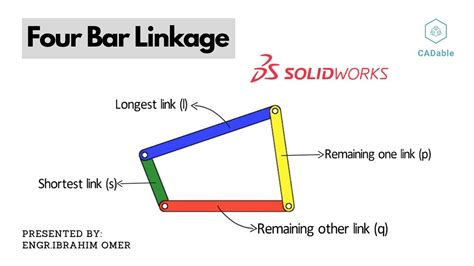

A 4 bar linkage consists of four rigid links connected by revolute joints, forming a closed-loop chain. This configuration allows for a wide range of motion, making it suitable for various tasks, such as grasping, manipulation, and locomotion. The links can be designed to have different lengths, shapes, and orientations, enabling the mechanism to adapt to specific requirements. By carefully selecting the link parameters, designers can create a 4 bar linkage that meets the desired performance criteria, including precision, speed, and payload capacity.

Design Considerations

When designing a 4 bar linkage, several factors must be taken into account. The link lengths, joint angles, and motion profiles all contribute to the overall performance of the mechanism. Grashof’s criterion is a fundamental concept in 4 bar linkage design, as it determines the feasibility of a particular configuration. By ensuring that the sum of the longest and shortest link lengths is less than or equal to the sum of the other two link lengths, designers can guarantee a smooth, continuous motion. Additionally, kinematic analysis is essential for predicting the linkage’s behavior, allowing designers to optimize the design for specific tasks and operating conditions.

| Link Parameter | Design Consideration |

|---|---|

| Link Length | Affects motion profile and range of motion |

| Joint Angle | Influences linkage's kinematic properties and stability |

| Motion Profile | Impacts linkage's performance, precision, and payload capacity |

Practical Applications

The 4 bar linkage has numerous practical applications in fields such as robotics, automation, and mechanical engineering. Its versatility and simplicity make it an attractive solution for tasks requiring precise motion, flexibility, and reliability. Industrial robots, for example, often employ 4 bar linkages in their manipulator arms to achieve high precision and dexterity. Similarly, mechanical grippers use 4 bar linkages to grasp and manipulate objects with delicate precision.

Key Points

- The 4 bar linkage is a fundamental mechanism in mechanical engineering, offering a wide range of motion and versatility.

- Grashof's criterion and kinematic analysis are essential design considerations for ensuring smooth, continuous motion.

- The linkage's performance, precision, and payload capacity can be optimized by carefully selecting link parameters and joint angles.

- Practical applications of the 4 bar linkage include industrial robots, mechanical grippers, and other mechanisms requiring precise motion and flexibility.

- A thorough understanding of the 4 bar linkage's dynamics and design principles is crucial for creating efficient and effective mechanisms.

Challenges and Limitations

While the 4 bar linkage offers many advantages, it also presents several challenges and limitations. Singularity is a critical issue, as it can cause the linkage to become unstable or even jam. Additionally, wear and tear on the joints and links can lead to reduced precision and performance over time. To mitigate these effects, designers must carefully consider the linkage’s dynamics, materials, and maintenance requirements.

In conclusion, the 4 bar linkage is a powerful mechanism with a wide range of applications in mechanical engineering and beyond. By understanding its design principles, advantages, and limitations, designers can create efficient, effective, and reliable mechanisms that meet specific performance criteria. Whether in robotics, automation, or other fields, the 4 bar linkage remains an essential component in many designs, offering a unique combination of simplicity, versatility, and precision.

What is the primary advantage of using a 4 bar linkage in mechanical systems?

+The primary advantage of using a 4 bar linkage is its ability to provide a wide range of motion, making it suitable for various tasks, including grasping, manipulation, and locomotion.

How does Grashof’s criterion affect the design of a 4 bar linkage?

+Grashof’s criterion determines the feasibility of a particular 4 bar linkage configuration, ensuring a smooth, continuous motion. It states that the sum of the longest and shortest link lengths must be less than or equal to the sum of the other two link lengths.

What are some common applications of the 4 bar linkage in industry?

+The 4 bar linkage has numerous practical applications in fields such as robotics, automation, and mechanical engineering. Examples include industrial robots, mechanical grippers, and other mechanisms requiring precise motion and flexibility.